Catering cooking fume purification equipment

A technology for oil fume purification and equipment, applied in the field of machinery, can solve the problems of easy expansion of gas path and oil path dredging, burst pipe, large space for aerodynamic oil mist to float up and so on, and improve the maintenance degree and pressure resistance adjustment degree. , avoid recoil gas path, improve the effect of dredging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

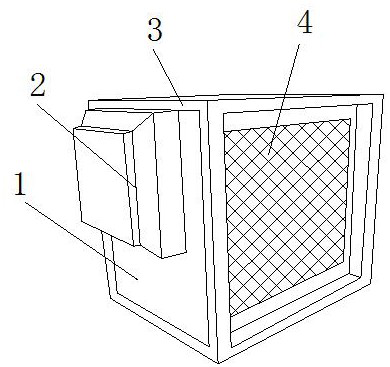

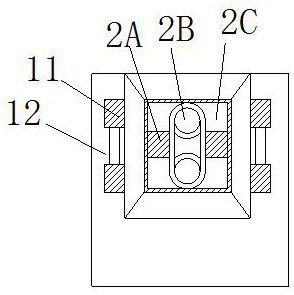

[0035] see Figure 1-Figure 8 , the present invention provides a cooking oil fume purification equipment, the structure of which includes: a side vertical plate 1, a wheel belt needle frame groove 2, a rib frame 3, a grid screen 4, the side vertical plate 1 and the wheel There are two frame grooves 2 with needle holders and they are installed on the left and right sides of the reinforcement frame 3 respectively. Above, the grid screening net 4 is inserted into the inside of the rib frame 3, the wheel belt needle holder frame groove 2 is mechanically connected with the reinforcement rib frame 3, and the wheel belt needle holder frame groove 2 is provided with a shuttle Needle row block 2A, needle plate wheel belt frame 2B, side frame slot seat 2C, the shuttle needle row block 2A is provided with two and installed on the left and right sides of the needle plate wheel belt frame 2B respectively, the shuttle row The needle block 2A and the needle plate wheel frame 2B adopt cleara...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a cooking fume purification equipment, the other aspects are the same as embodiment 1, the difference is:

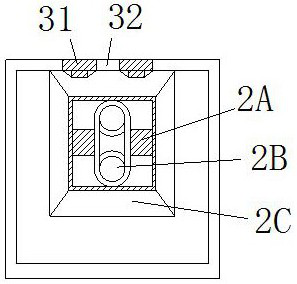

[0044] see image 3 , the rib frame 3 is composed of a buckle frame block 31 and a frame rod frame 32, the buckle frame block 31 is installed on the top of the frame rod frame 32, and the buckle frame block 31 and the frame rod frame 32 adopt an interference fit , the operation effect of the top hoisting wheel grooved shell is formed in the frame bar frame 32 through the hanging buckle frame block 31 .

[0045] see Figure 6 , the buckle frame block 31 is composed of a buckle block body 311 and a cover buckle cap 312, the buckle block body 311 is installed on the top of the cover buckle cap 312, and the buckle block body 311 and the cover buckle cap 312 are buckled together And on the same vertical plane, the cover buckle cap 312 is a trapezoidal cover cap groove structure with double locking pins and bent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com