Intelligent crude-oil desulfurization equipment

A technology for desulfurization equipment and crude oil, applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of no large-scale industrial production, small adsorption capacity of adsorbents, and low oil yield, etc., and is easy to scale up. The effect of capacity expansion, low hydrogen consumption and low octane loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

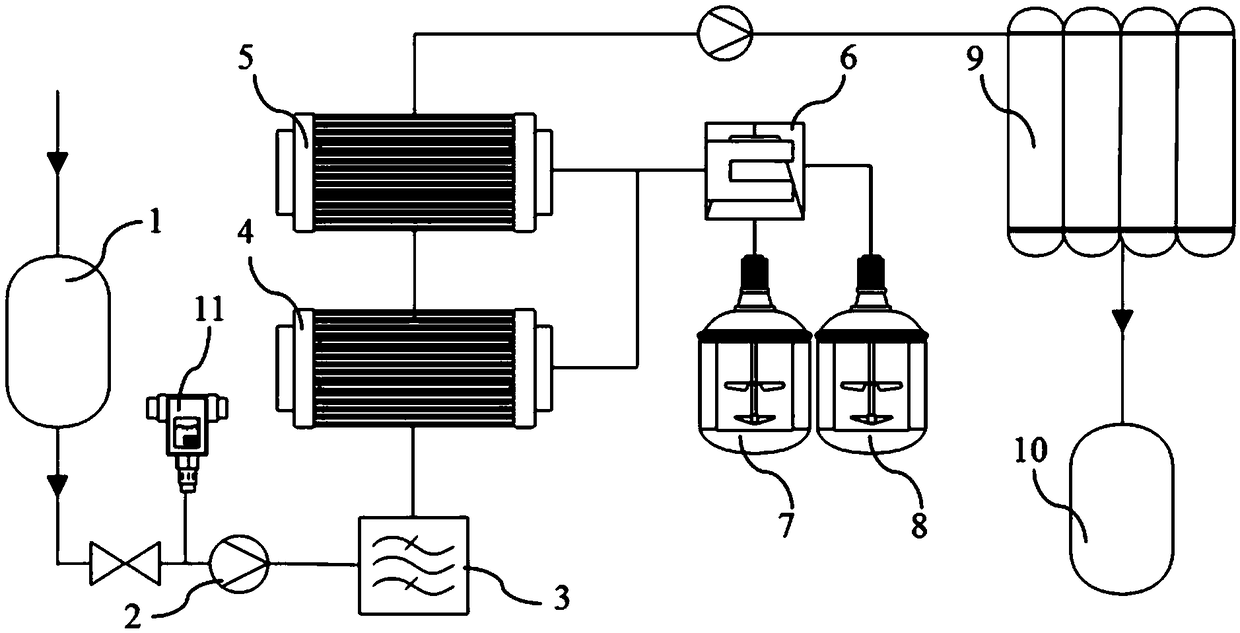

[0023] The invention particularly relates to a membrane separation-biological desulfurization coupling FCC gasoline raw material desulfurization equipment, such as figure 1 As shown, the crude oil desulfurization equipment includes a crude oil stream 1, which is transported into a filter 3 through a feed pump 2, an intelligent analysis instrument 11 is arranged at the crude stream 1, and the filter 3 is connected to a first Membrane reactor 4, described first membrane reactor 4 is connected with first vacuum pump, and described first membrane reactor 4 is also connected with second membrane reactor 5, and described second membrane reactor 5 is connected with second vacuum pump , the first membrane reactor 4 and the second membrane reactor 5 are provided with a plurality of plate-and-frame membrane modules separated from each other along the vertical axis, the first membrane reactor 4 and the second membrane reactor 5 are respectively connected to Graded condensing 6 equipment ...

Embodiment 2

[0025] The membrane reactor provided by the present invention includes a deep desulfurization permeable membrane made of a plate-and-frame membrane module. In actual production, it can be installed according to the permeation direction according to the crude oil treatment requirements, and the required membrane area can be obtained by connecting in series. The deep desulfurization permeable The dissolution and diffusion capabilities of the membrane are different under different conditions. During the pervaporation process, the recovered product is selected according to the permeation flux. The sulfur-containing compounds in the middle distillate and heavy distillate gasoline are mainly thiophene and its derivatives. The specific method of the present invention A deep desulfurization permeable membrane for thiophene and its derivatives is provided, preferably, it has an excellent effect on removing sulfides, disulfides, and thiophenes in gasoline, and the specific manufacturing s...

Embodiment 3

[0031] Prepare a bioreactor, the core reaction element of the bioreactor is polyacrylamide gel-embedded immobilized cell particles of active microorganisms, the production steps of the immobilized cell particles are as follows:

[0032]Step 31. Take appropriate proportions of Rhodococcus erythropolis, Thiobacillus thiooxidans, Thiobacillus usthioparus, Thiobacillus ferrooxidans and Thiobacillus denitrificans) culture, the ratio is 10:2:1:1:1, and the above strains are all commercially available strains;

[0033] Step 32. Dissolve the mixed bacterial suspension in sterile water so that the total cell mass of the mixed bacterial suspension reaches 50g / L, add 65.5g / L acrylamide to 1L of the mixed bacterial solution, add 200ml of 2.5g / L BIS, Then add 200ml of 20ml / L APS and 2 drops of tetramethylethylenediamine, and ice bath for 30 minutes to obtain immobilized cell particles;

[0034] Step 33: Fill the immobilized cell granules into the bioreactor and keep still, adjust the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com