Method for testing dispersity of SBS modifier in asphalt mixture

A technology of asphalt mixture and testing method, which is applied in the direction of material analysis, measuring device, analyzing material by optical means, etc., can solve the problems of lack of scientificity and rigor, unmeasured actual value, unspecific, etc. Simplification of the environment, good practicality and promotion value, the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for testing the dispersibility of SBS modifier in asphalt, comprising the following steps:

[0035] (1) Disperse sampling is carried out on the modified asphalt mixture to be tested. The sampling position should be clearly differentiated, including the edge, center, bottom layer, and surface layer; add an appropriate amount of carbon tetrachloride (CCl 4 ) to dissolve the sample to obtain a solution for subsequent use;

[0036] (2) Use the calcium fluoride or potassium bromide slide penetration method to carry out infrared testing on the solution of step (1); with the blank slide as the background, the background scan time is 64 times, the sample scan time is 64 times, and the scan speed 7.5KHz, reserved 4000-600cm -1 The data in the interval, the resolution is 4cm -1 ;

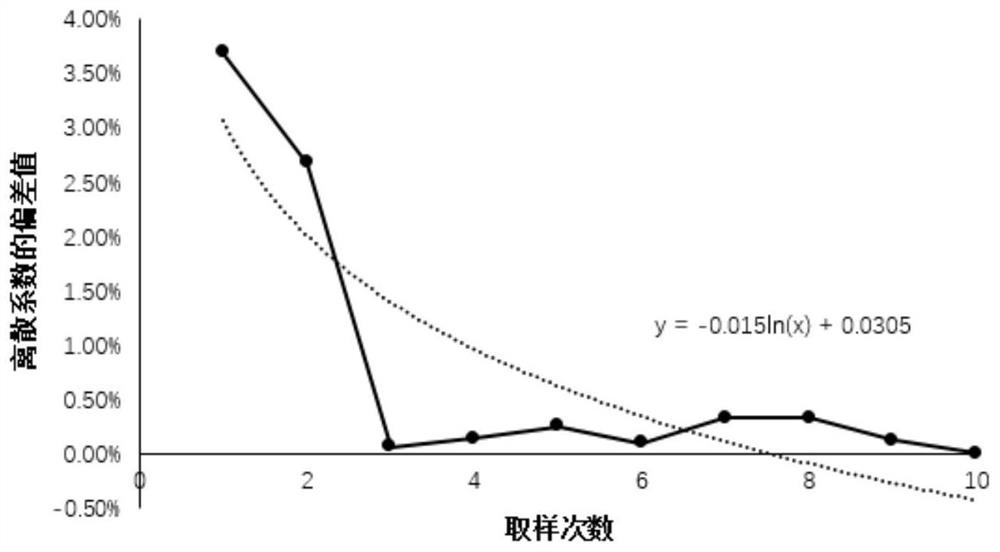

[0037] (3) Carry out quantitative analysis to the infrared image of gain, use OPUS software to carry out integral to infrared spectrogram, integrate infrared spectrogram, calculate the area...

Embodiment 2

[0051] In this embodiment, an absorbance-concentration standard curve is drawn with a series of preconfigured concentration gradients of SBS modified asphalt. Both infrared acquisition and data processing use OPUS software, and other data processing software with integral functions can also be used. The area ratio Z after integration i The discrete calculation can use any data processing software.

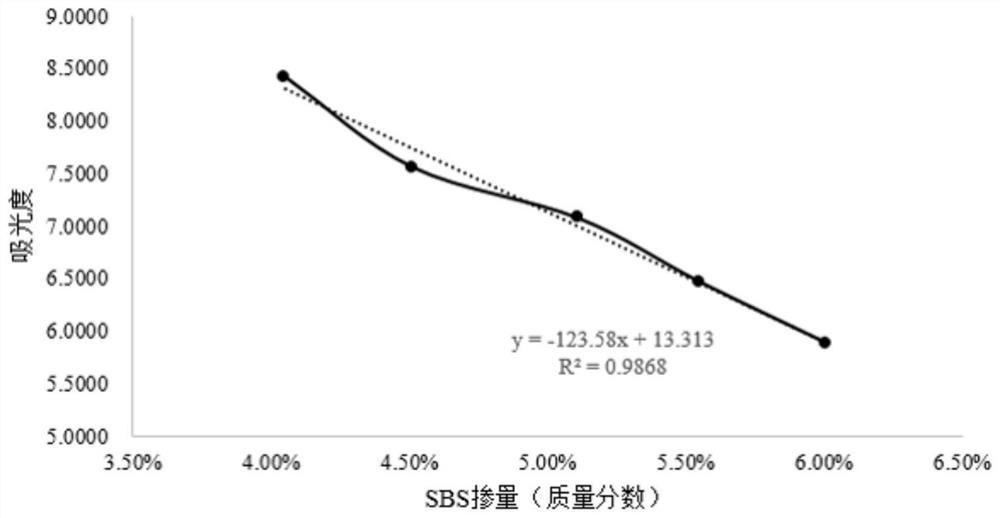

[0052] Establishment of Absorbance-Dry SBS Dosage Standard Curve

[0053] A certain amount of dry-process SBS modifier particles and No. 70 matrix asphalt were weighed with an analytical balance, dissolved in carbon tetrachloride, and made into a specified concentration of SBS modified asphalt solution. The concentration gradient was set at 4%-6%. 5 groups were set up, and 5 parallel samples were set for each group concentration. When performing infrared measurement, if there is no abnormality in the data of this test, you can move the slide and select a position with a differen...

Embodiment 3

[0058] In this embodiment, the SMA-13 gradation is taken as an example to determine the optimal mixing time of dry SBS under the SMA-13 gradation. Add 7% dry-process SBS modifier to No. 70 asphalt, use basalt coarse aggregate and limestone fine aggregate as stone materials, and set three different mixing times.

[0059] Carry out SBS dispersibility analysis to prepared three groups of mixtures by the method described in the present invention, and Marshall stability test, freeze-thaw splitting experiment, rutting experiment etc., analyze the influence of mixing time on SBS dispersibility, and The effect of the dispersion of dry SBS modifier in asphalt mixture on the macroscopic performance of the specimen.

[0060] 1. Preparation of dry SBS modified asphalt mixture:

[0061] (1) Dry-mix the dry-process SBS modifier and hot aggregate for 60 / 90 / 120s, so that the dry-process SBS modifier is evenly dispersed in the mineral material;

[0062] (2) Add asphalt according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com