Preparation method of polydopamine ball anchored Pd nanoparticle catalyst

A technology of polydopamine spheres and nanoparticles, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems such as complex preparation process, low reactivity, and poor catalyst stability, and achieve simplified preparation Process, improve catalytic performance, reduce the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

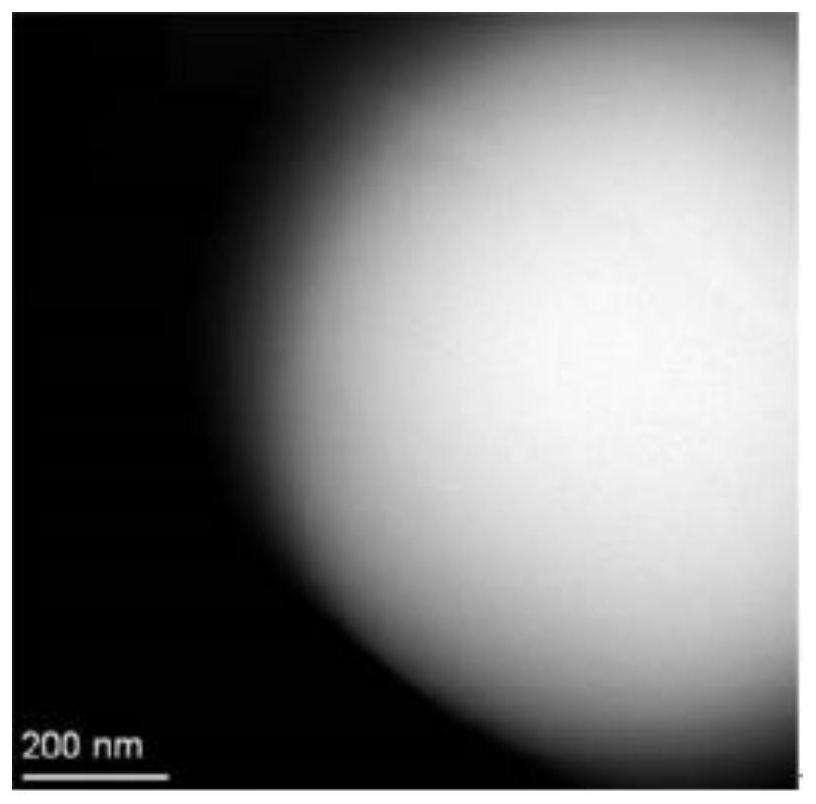

[0035] The preparation of 1wt%-Pd / PDA-0h catalyst:

[0036] Measure 38mL absolute ethanol, 190mL 10mmol / L Tris solution, weigh 291mg DA and 0.4mL0.07035mol / L H 8 Cl 4 N 2 Pd solution was added into a 250mL beaker, stirred at 25°C for 24h, filtered with suction to obtain a black solid, and dried under vacuum at 60°C for 12h. sample at 200°C in H 2 / N 2 (1:1) mixed atmosphere reduction 1h, H 2 with N 2 The flow rate is 20mL / min. Named 1wt%-Pd / PDA-Oh.

Embodiment 2

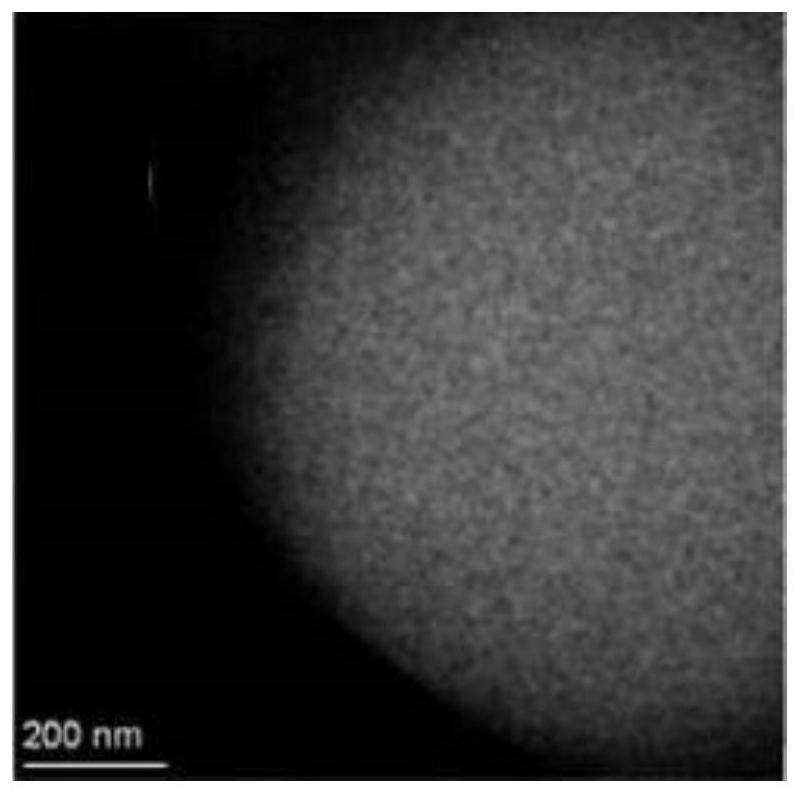

[0038] The preparation of 3wt%-Pd / PDA-0h catalyst:

[0039] Measure 38mL absolute ethanol, 190mL 10mmol / L Tris solution, weigh 291mg DA and 1.2mL0.07035mol / L H 8 Cl 4 N 2 Pd solution was added into a 250mL beaker, stirred at 25°C for 24h, filtered with suction to obtain a black solid, and dried under vacuum at 60°C for 12h. sample at 200°C in H 2 / N 2 (1:1) mixed atmosphere reduction 1h, H 2 with N 2 The flow rate is 20mL / min. Named 3wt%-Pd / PDA-Oh.

Embodiment 3

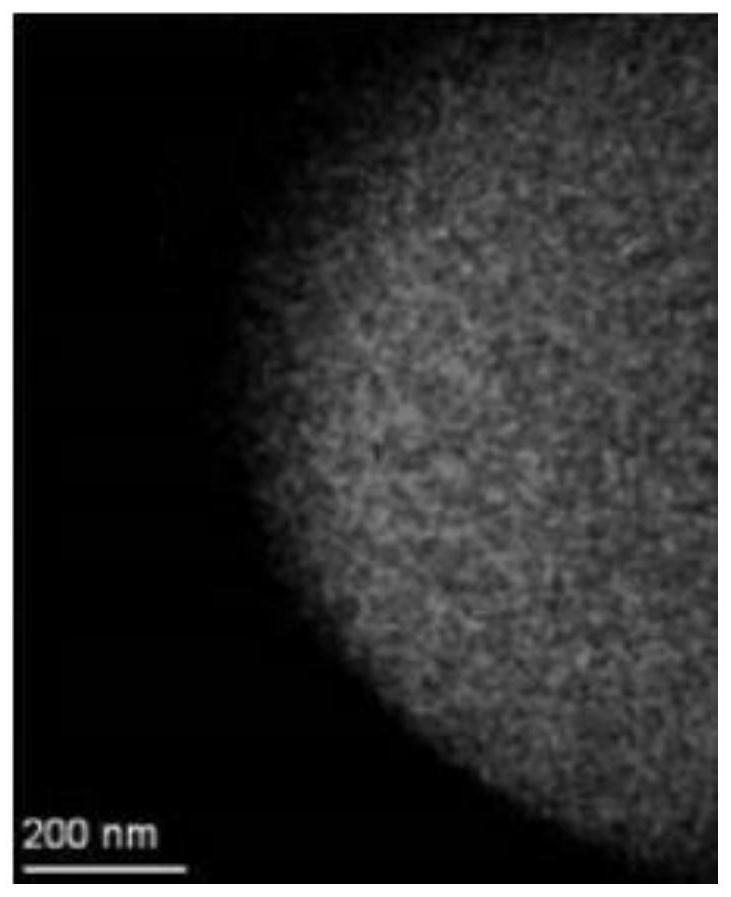

[0041] The preparation of 5wt%-Pd / PDA-0h catalyst:

[0042] Measure 38mL absolute ethanol, 190mL 10mmol / L Tris solution, weigh 291mg DA and 2mL0.07035mol / L H 8 Cl4 N 2 Pd solution was added into a 250mL beaker, stirred at 25°C for 24h, filtered with suction to obtain a black solid, and dried under vacuum at 60°C for 12h. sample at 200°C in H 2 / N 2 (1:1) mixed atmosphere reduction 1h, H 2 with N 2 The flow rate is 20mL / min. Named 5wt%-Pd / PDA-Oh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com