Method for modifying silicoaluminophosphate molecular sieve, modified molecular sieve and application thereof

A silicoaluminophosphate, molecular sieve technology, applied in molecular sieve catalyst, molecular sieve and alkali exchange phosphate, chemical instruments and methods, etc., can solve the problems of high cost, complicated operation process, etc. Effects of Reaction Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] To prepare SAPO-34 molecular sieve with hierarchical pore structure, the raw material is taken from the conventional SAPO-34 molecular sieve A prepared according to [Comparative Example 1], which only contains micropores.

[0034] Weigh 30g of molecular sieve A and place it in a 0.03M acidic solution, wherein the acidic solution is a mixed solution of nitric acid and citric acid, the ratio of the two before and after is 8:1, the amount of the solution is 0.9L, and stirred at 75°C After 3 hours, product B was obtained after filtering, washing, drying and roasting.

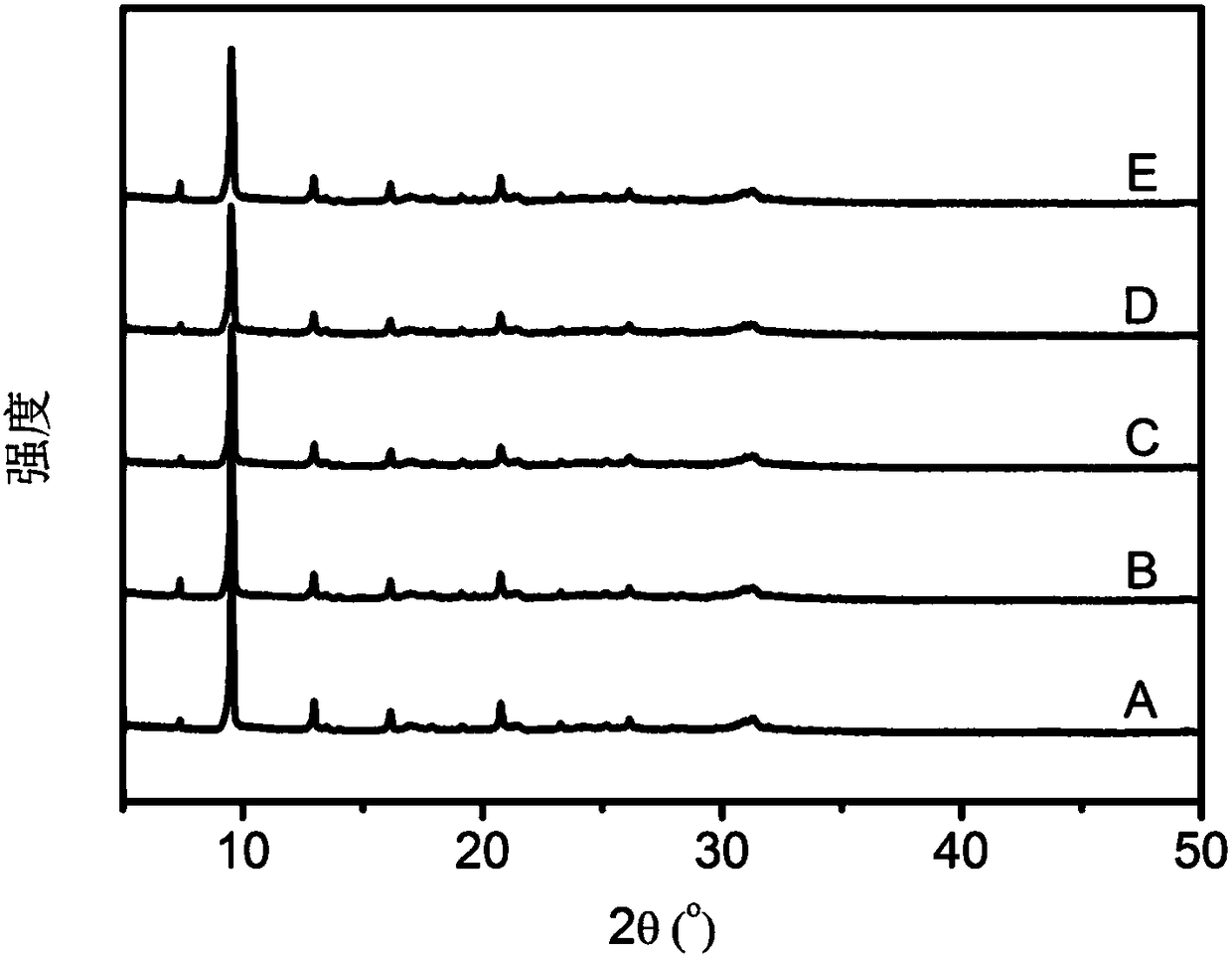

[0035] The XRD spectrum of B is as figure 1 shown, from figure 1 It can be seen that the synthesized molecular sieve has the characteristic diffraction peaks of SAPO-34 molecular sieve, indicating that the prepared product is pure SAPO-34 molecular sieve with a relative crystallinity of 92%.

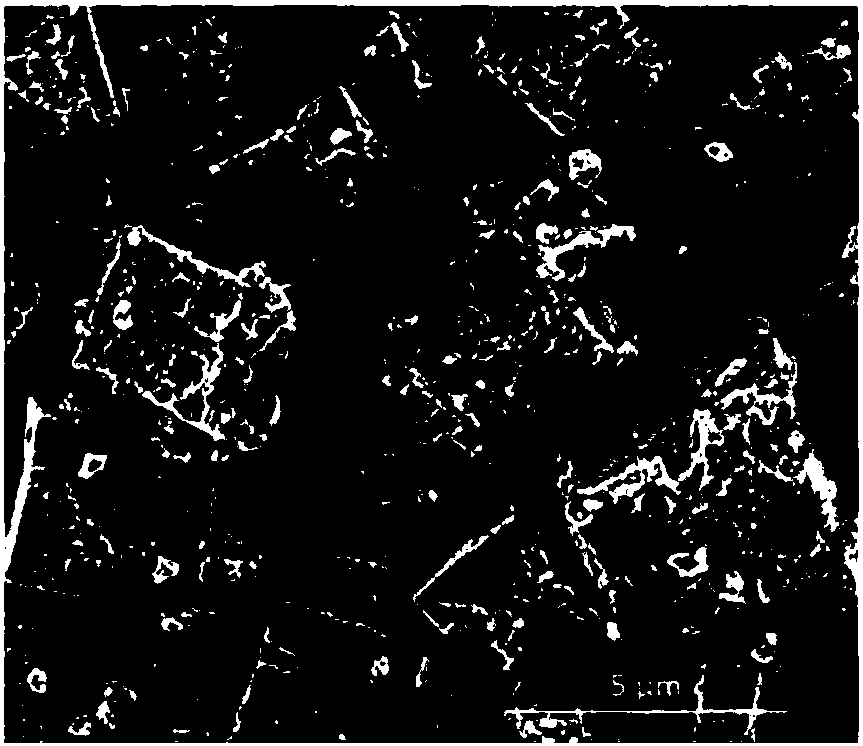

[0036] The SEM photograph of B is as image 3 As shown, obvious pore structure appeared on the surface of molecula...

Embodiment 2

[0040] Same as [Example 1], except that the raw material used is the conventional SAPO-34 molecular sieve A roasted product prepared according to the method of [Comparative Example 1], which only contains micropores. The final obtained SAPO-34 molecular sieve with hierarchical pore structure is denoted as C.

[0041] The XRD spectrum of C is as figure 1 shown, from figure 1 It can be seen that the prepared molecular sieve has the characteristic diffraction peaks of SAPO-34 molecular sieve, indicating that the prepared product is pure SAPO-34 molecular sieve with a relative crystallinity of 90%.

[0042] SEM photographs of C with image 3 similar.

[0043] C The micropore diameter is distributed in 0.3-0.5nm, the mesopore diameter is distributed in 8-25nm, and the macropore diameter is distributed in 50-250nm; the pore volume contributed by the micropore is 0.19cm 3 / g, the pore volume contributed by mesopores is 0.20cm 3 / g, the pore volume contributed by macropores is 0....

Embodiment 3

[0046] Same as [Example 1], except that the treatment process is divided into two steps, first treat in 0.1L of 0.01M nitric acid solution for 1 hour, after filtering, washing and drying, then treat in 0.8L of 0.03M citric acid solution 2h, the obtained product is marked as D.

[0047] The XRD spectrum of D is as figure 1 shown, from figure 1 It can be seen that the synthesized molecular sieve has the characteristic diffraction peaks of SAPO-34 molecular sieve, indicating that the synthesized product is pure SAPO-34 molecular sieve with a relative crystallinity of 92%.

[0048] The SEM photograph of D with image 3 similar.

[0049] D The micropore diameter is distributed in 0.3-0.5nm, the mesopore diameter is distributed in 5-20nm, and the macropore diameter is distributed in 50-200nm; the pore volume contributed by the micropore is 0.20cm 3 / g, the pore volume contributed by mesopores is 0.21cm 3 / g, the pore volume contributed by macropores is 0.19cm 3 / g; the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com