Rare earth-doped NaYF4/Au@CdS composite photocatalyst and preparation method thereof

A rare earth doping, composite light technology, applied in the field of photocatalysis, to achieve the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

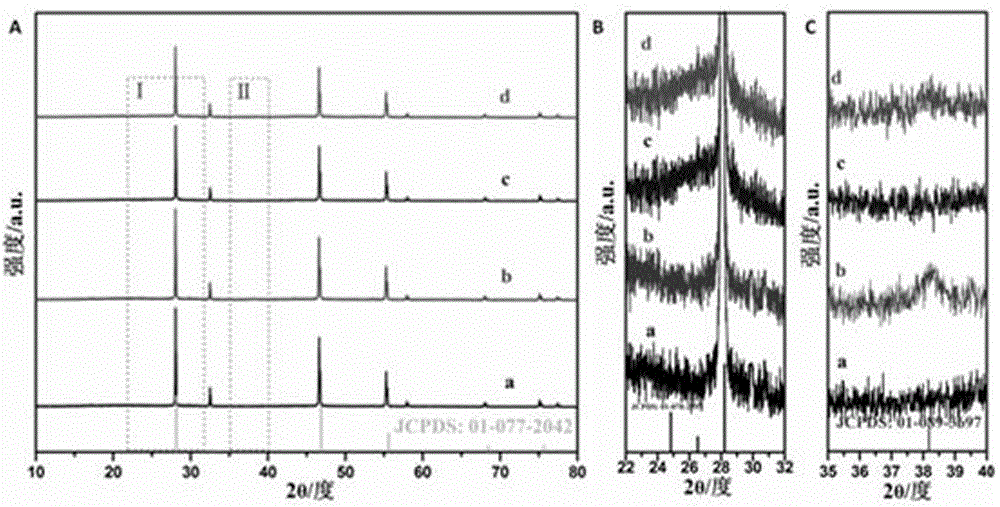

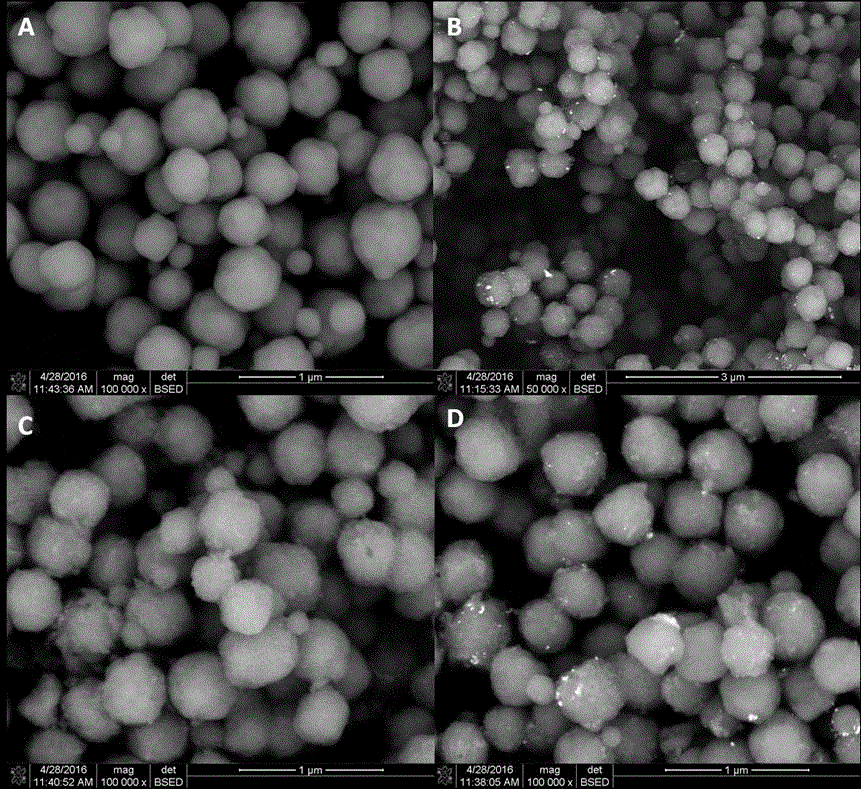

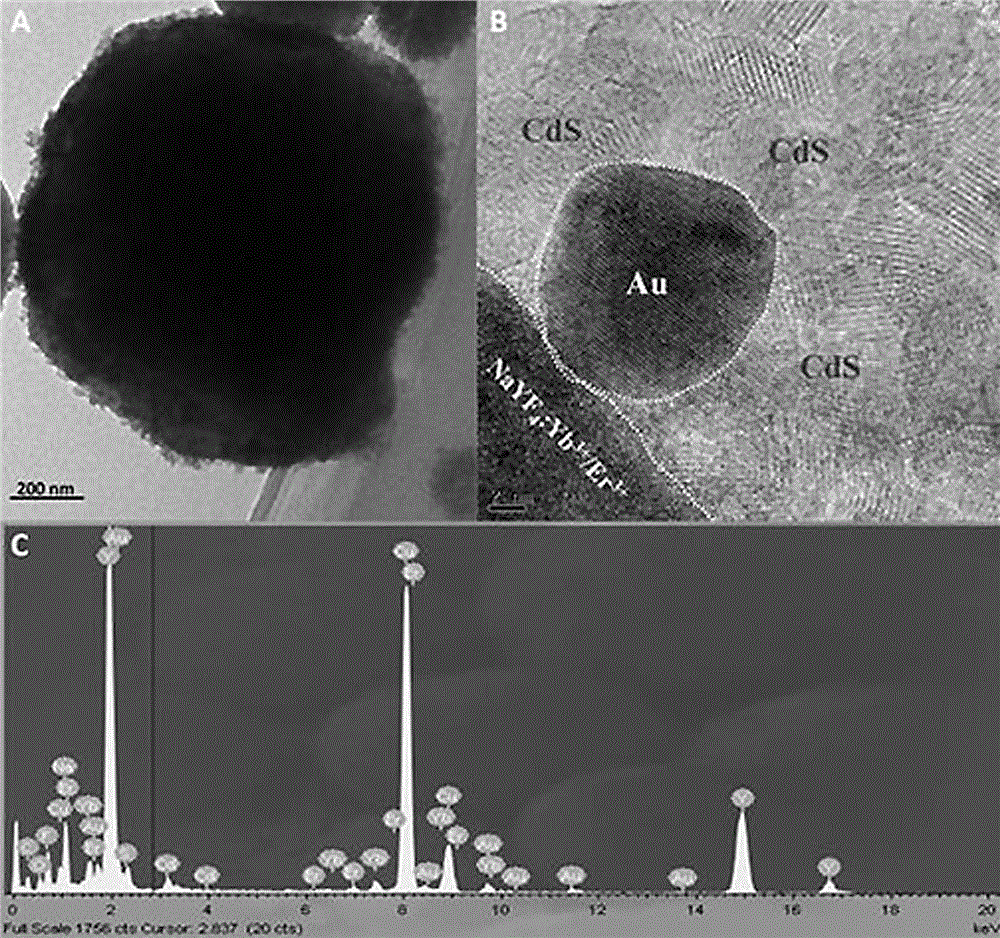

[0029] NaYF 4 :Yb 3+ / Er 3+ / Au@CdS composite photocatalyst preparation:

[0030] (1) Preparation of NaYF 4 :Yb 3+ / Er 3+ Microspheres:

[0031] At a temperature of 60°C and a stirring speed of 300r / min, 1.408mmol Y(NO 3 ) 3 •6H 2 O,0.16mmol Yb(NO 3 ) 3 • 5H 2 O, 0.032mmol Er(NO 3 ) 3 • 5H 2 O was dissolved in 20mL water; 1.6mmol EDTA was dissolved in 20mL water; 14.4mmol NaF was dissolved in 20mL water, and the above rare earth nitrate solution, surfactant and fluorine source solution were mixed and stirred for 1h to form a reaction precursor solution; The obtained precursor solution was transferred into a sealed 100mL polytetrafluoroethylene-lined reaction kettle, heated to 180°C, and kept for 3h; cooled to room temperature, washed with deionized water and absolute ethanol three times, and centrifuged to collect the precipitate. NaYF can be obtained by vacuum drying at 60°C 4 :Yb 3+ / Er 3+ microspheres;

[0032] (2) Preparation of NaYF 4 :Yb 3+ / Er 3+ ...

Embodiment 2

[0040] NaYF 4 :Yb 3+ / Er 3+ / Au@CdS composite photocatalyst preparation:

[0041] (1) Preparation of NaYF 4 :Yb 3+ / Er 3+ Microspheres:

[0042] At a temperature of 50°C and a stirring speed of 100r / min, 1.408mmol Y(NO 3 ) 3 •6H 2 O,0.28mmol Yb(NO 3 ) 3 • 5H 2 O, 0.141mmol Er(NO 3 ) 3 • 5H 2 O was dissolved in 20mL water; 1.4mmol sodium citrate was dissolved in 20mL water; 20mmol NaF was dissolved in 20mL water, and the above rare earth nitrate solution, surfactant and fluorine source solution were mixed and stirred for 1h to form a reaction precursor solution; Transfer the obtained precursor solution into a sealed 100mL polytetrafluoroethylene-lined reaction kettle, raise the temperature to 160°C, and keep it warm for 2h; cool to room temperature, wash with deionized water and absolute ethanol three times respectively, and centrifuge to collect the precipitate , NaYF was obtained by vacuum drying at 60°C 4 :Yb 3+ / Er 3+ microspheres;

[0043] (2) Preparati...

Embodiment 3

[0050] NaYF 4 :Yb 3+ / Er 3+ / Au@CdS composite photocatalyst preparation:

[0051] (1) Preparation of NaYF 4 :Yb 3+ / Er 3+ Microspheres:

[0052] At a temperature of 70°C and a stirring speed of 500r / min, 1.408mmol Y(NO 3 ) 3 •6H 2 O,0.08mmol Yb(NO 3 ) 3 • 5H 2 O, 0.0141mmol Er(NO 3 ) 3 • 5H 2 O was dissolved in 20mL water; 1.5mmol EDTA was dissolved in 20mL water; 6mmol NaF was dissolved in 20mL water, the above rare earth nitrate solution, surfactant solution and fluorine source solution were mixed and stirred for 1h to form a reaction precursor solution; The obtained precursor solution was transferred into a sealed 100mL polytetrafluoroethylene-lined reaction kettle, heated to 170°C, and kept for 6h; cooled to room temperature, washed three times with deionized water and absolute ethanol, and centrifuged to collect the precipitate. NaYF can be obtained by vacuum drying at 60°C 4 :Yb 3+ / Er 3+ microspheres;

[0053] (2) Preparation of NaYF 4 :Yb 3+ / Er ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com