Nitrogen-sulfur-doped porous carbon-modified carbon nanotube-supported Pt-Ni alloy catalyst and preparation method thereof

A technology of alloy catalysts and nanotubes, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. control, less functional sites, etc., to achieve the effects of improving dispersion and stability, highlighting catalytic reaction performance, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step a): At 25°C, weigh 0.1 g of carboxylated carbon nanotubes and 50 mL of N,N-dimethylformamide, add carboxylated carbon nanotubes into N,N-dimethylformamide, and ultrasonically disperse 15min, then add 0.7g 2,5-dihydroxythiophene, 0.22g triethylenediamine and 1.213g nickel nitrate hexahydrate, continue ultrasonic dispersion for 15min, transfer to the reaction kettle, react at 130°C for 12h, naturally cool to room temperature, Centrifuge, wash twice with N,N-dimethylformamide and ethanol successively, and dry under vacuum at 65°C for 12 hours to prepare carboxylated carbon nanotubes / Ni-MOF.

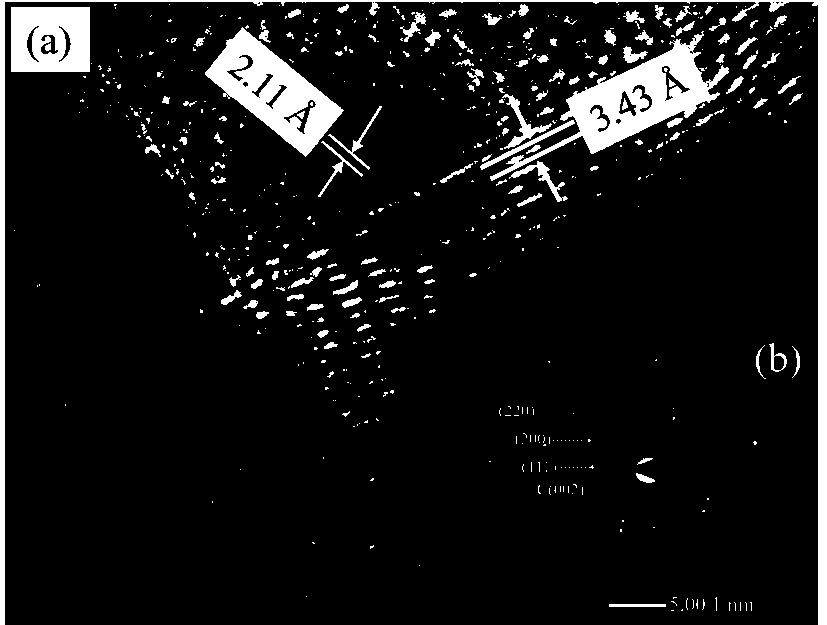

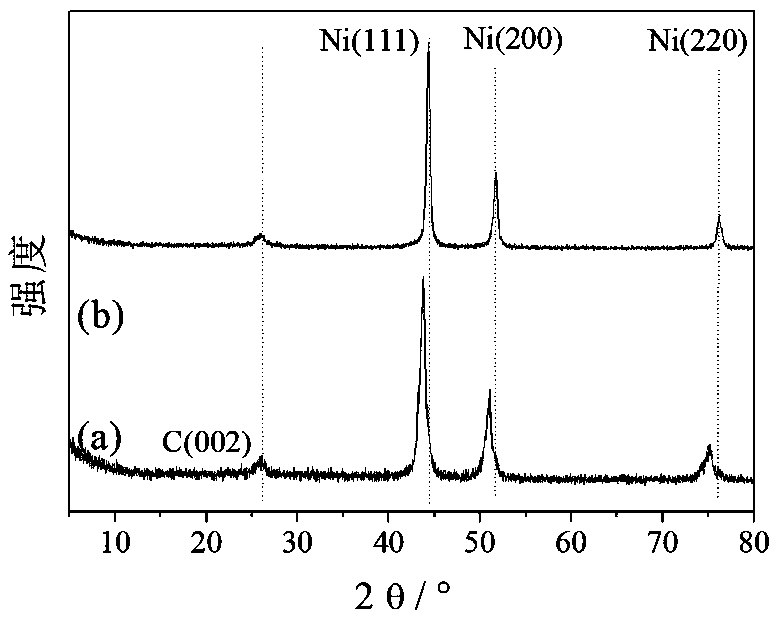

[0030] Step b): At 25°C, take 0.1 g of the above-prepared carboxylated carbon nanotubes / Ni-MOF, add 100 mL of deionized water, add 2 mL of trisodium citrate aqueous solution with a concentration of 2 wt % and 0.5 mL of a solution with a concentration of 0.5 Wt% aqueous solution of potassium chloroplatinite was ultrasonically dispersed for 30 min, then 4 mL of 0.2 wt% sodium boroh...

Embodiment 2

[0039] The nitrogen-sulfur-doped porous carbon-modified carbon nanotube-loaded Pt-Ni alloy catalyst prepared in Example 1 was applied to the electrocatalytic hydrogen evolution reaction under alkaline conditions, specifically, the nitrogen-sulfur-doped carbon nanotube prepared in Example 1 Porous carbon-modified carbon nanotubes loaded with Pt-Ni alloy catalyst-modified glassy carbon electrode as the working electrode, mercury / mercury oxide electrode as the reference electrode, platinum sheet electrode as the counter electrode, and the electrolyte is 1mol / L potassium hydroxide solution.

[0040] Tested by linear voltammetry sweep, by Figure 5 The voltammetric sweep curve shown can be calculated at a current density of 10mA / cm 2 The lower overpotential is only 0.062V (vs RHE), showing that the catalyst prepared in Example 1 produces a synergistic effect among the components, which improves the catalytic performance of the catalyst.

Embodiment 3

[0042] Step a): At 25°C, weigh 0.1 g of carboxylated carbon nanotubes and 20 mL of N,N-dimethylformamide, add carboxylated carbon nanotubes into N,N-dimethylformamide, and ultrasonically disperse 20min, then add 2g 2,5-dihydroxythiophene, 0.22g triethylenediamine and 1.542g nickel chloride, continue to ultrasonically disperse for 20min, transfer to the reaction kettle, react at 130°C for 24h, naturally cool to room temperature, centrifuge, Washed twice with N,N-dimethylformamide and ethanol successively, and dried in vacuum at 90°C for 8 hours to obtain carboxylated carbon nanotubes / Ni-MOF.

[0043] Step b): At 25°C, take 0.1g of the above-prepared carboxylated carbon nanotubes / Ni-MOF, add 100mL of deionized water, add 0.5mL of 4wt% trisodium citrate aqueous solution and 0.2mL of 2wt% aqueous solution of potassium chloroplatinite was ultrasonically dispersed for 30 minutes, then 4 mL of 0.2wt% sodium borohydride aqueous solution was added, ultrasonically dispersed for 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com