Double microporous-mesoporous composite molecular sieve and preparation method thereof

A composite molecular sieve and microporous technology, which is applied in molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve problems such as ternary dual microporous-mesoporous composite molecular sieves that have not been reported, and achieve large-scale industrial applications. value, the effect of good catalytic reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

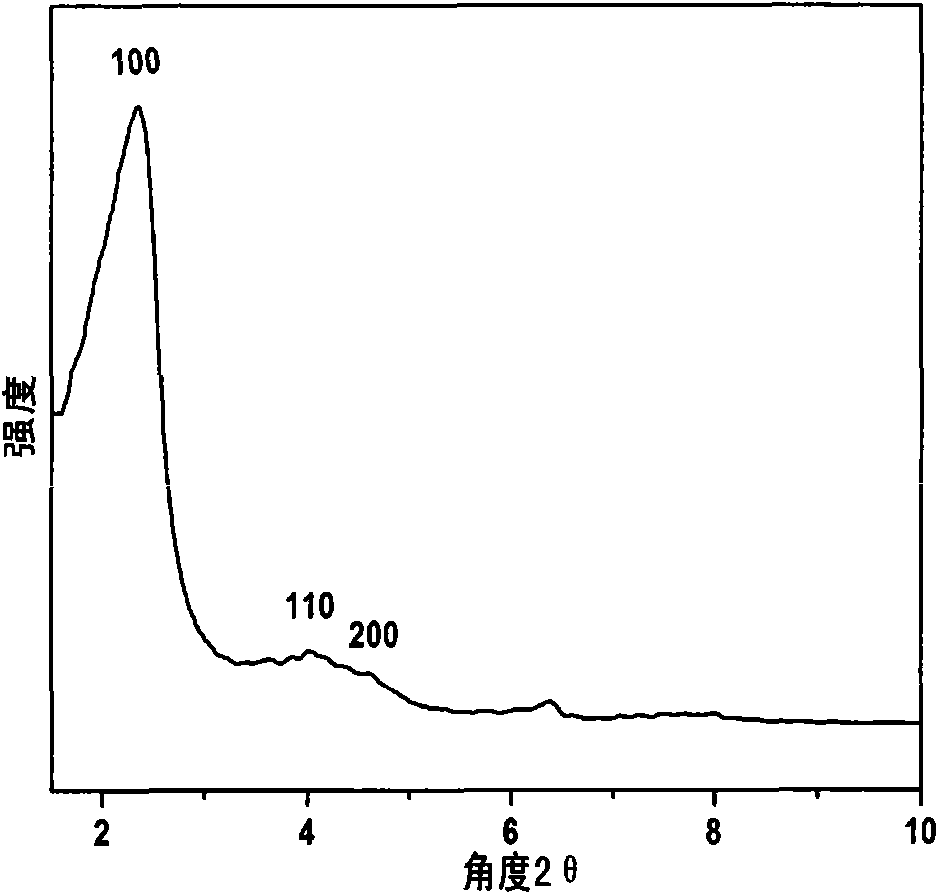

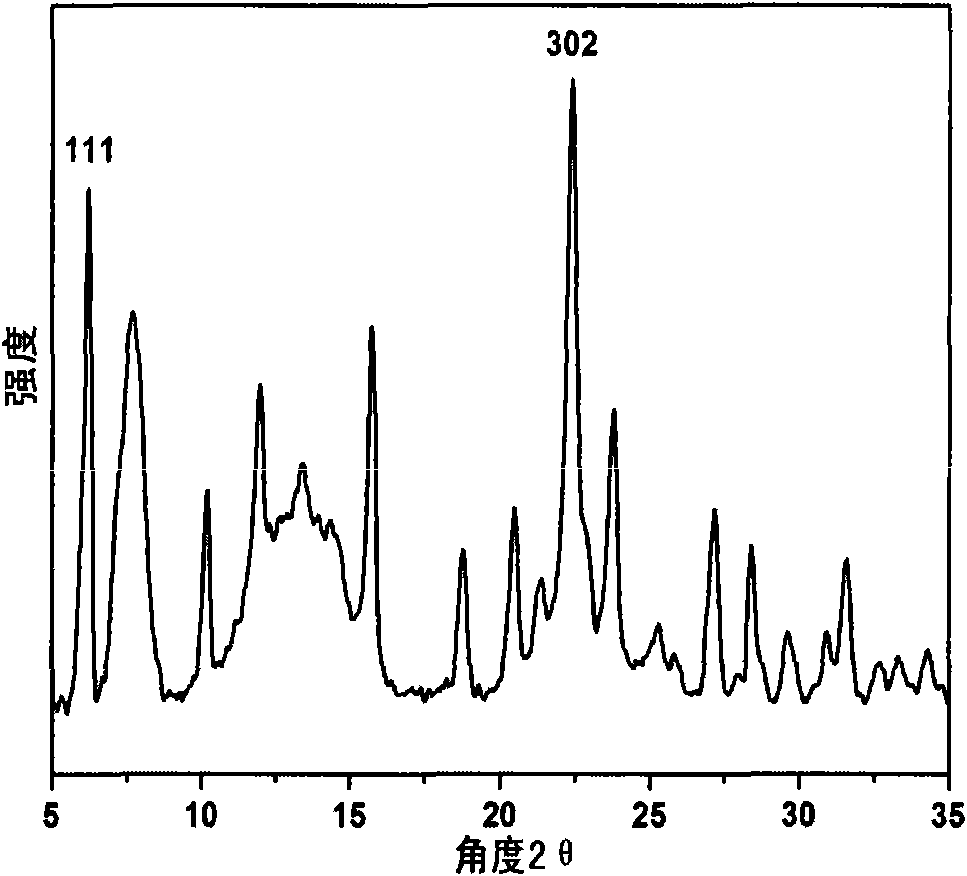

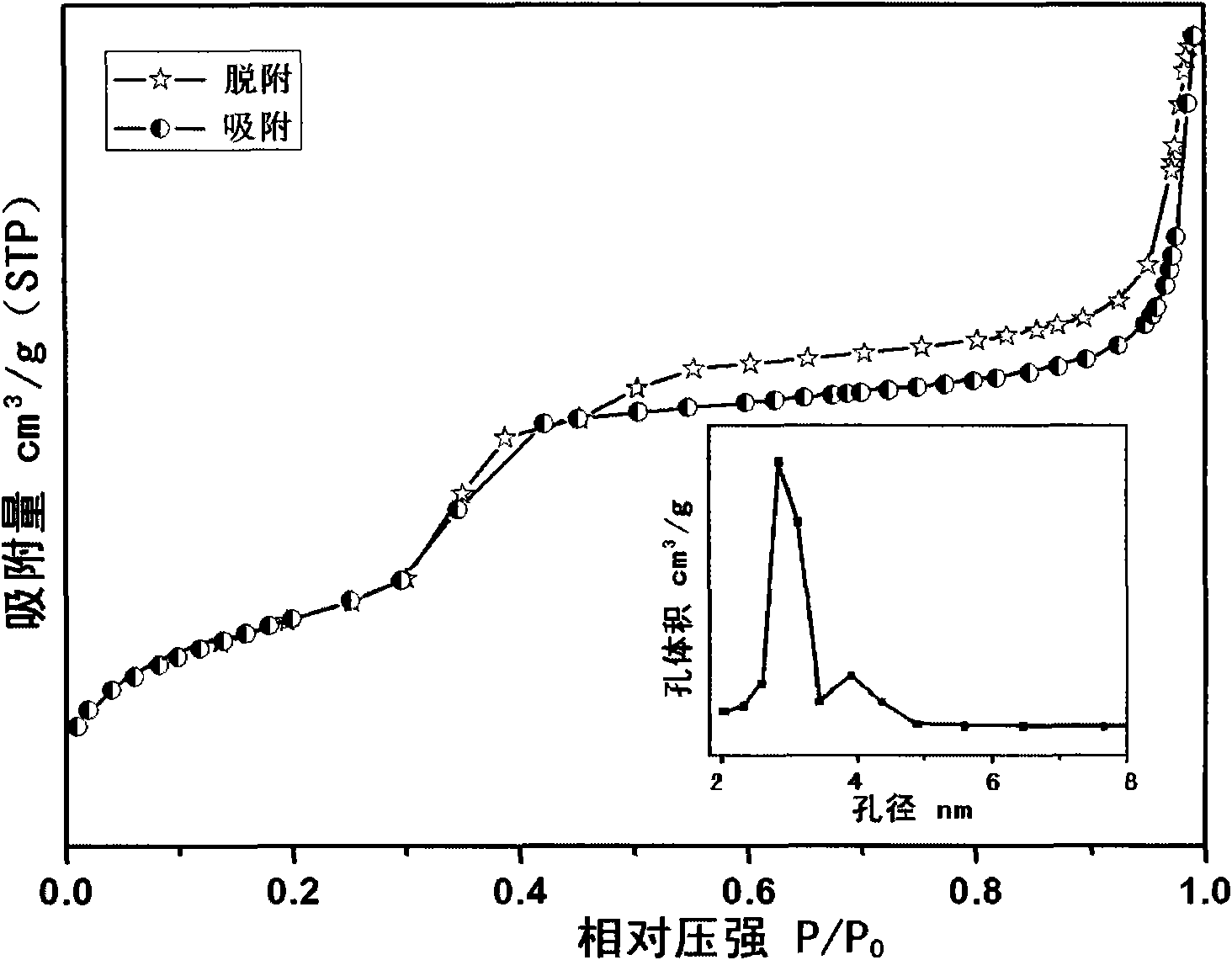

Embodiment 1

[0041] 0.47g Y-type and 0.47g Beta-type zeolite powders were mixed and pretreated and added to the mixed solution containing CTAB and OP-10, stirred at room temperature for 30min, then slowly added dropwise 5ml of water glass (SiO 2 25.4%, Na 2 O 7.4%), slowly add 0.389gAl after 5min 2 (SO 4 ) 3 18H 2 O, the raw material molar ratio is 1SiO 2 :0.15CTAB:0.025OP-10:x(Y+Beta):0.02Al 2 o 3 : 0.28Na 2 O: 60H 2 O, where (Y+Beta) / SiO 2 (mass ratio) = 0.53. After stirring for 1.0h, adjust the pH of the system to 11.1, continue to stir for 30min, put the glue into a lined reactor, and crystallize at 100°C for 48h. The product is suction filtered, washed, dried, and roasted. Ion exchange in 0.10mol / L ammonium nitrate solution at a ratio of 1:200 for 2.5h, suction filtration, drying, and finally roasting in the air to obtain an alkaline system. It is a 53% Y-Beta / MCM-41 double microporous-mesoporous composite molecular sieve, and this sample is named MYβ-1.

[0042] Depend o...

Embodiment 2

[0048] 0.47g Y-type and 0.47g Beta-type zeolite powders were mixed and pretreated and added to the mixed solution containing CTAB and OP-10, stirred at room temperature for 30min, then slowly added dropwise 5ml of water glass (SiO 2 25.4%, Na 2 O 7.4%), slowly add 0.156gAl after 5min 2 (SO 4 ) 3 18H 2 O, the raw material molar ratio is 1SiO 2 :0.15CTAB:0.025OP-10:x(Y+Beta):0.008Al 2 o 3 : 0.28Na 2 O: 60H 2 O, where (Y+Beta) / SiO 2 (mass ratio) = 0.53. After stirring for 1.0h, adjust the pH of the system to 11.1, continue to stir for 30min, put the glue into a lined reactor, and crystallize at 100°C for 48h. The product is filtered, washed, dried, and roasted. Ion exchange in 0.15mol / L ammonium chloride solution at a ratio of 1:300 for 2.0h, suction filtration, drying, and finally roasting in the air to obtain the Y-Beta / MCM with Si / Al=62.5 for the synthesis of alkaline system -41 double microporous-mesoporous composite molecular sieve, this sample is named MYβ-2.

Embodiment 3

[0050] 0.235g Y-type and 0.235g Beta-type zeolite powders were mixed and pretreated and added to the mixed solution containing CTAB and OP-10, stirred at room temperature for 30min, then slowly added dropwise 5ml of water glass (SiO 2 25.4%, Na 2 O 7.4%), slowly add 0.389gAl after 5min 2 (SO 4 ) 3 18H 2 O, the raw material molar ratio is 1SiO 2 :0.15CTAB:0.025OP-10:x(Y+Beta):0.02Al 2 o 3 : 0.28Na 2 O: 60H 2 O, where (Y+Beta) / SiO 2 (mass ratio) = 0.27. After stirring for 1.0h, adjust the pH of the system to 11.1, continue to stir for 30min, put the glue into a lined reactor, and crystallize at 100°C for 48h. The product is suction filtered, washed, dried, and roasted. Ion exchange in 0.10mol / L ammonium nitrate solution at a ratio of 1:200 for 2.5h, suction filtration, drying, and finally roasting in the air to obtain an alkaline system with a ratio of micropores of 1:1 and a relative content of 27% Y-Beta / MCM-41 double microporous-mesoporous composite molecular sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com