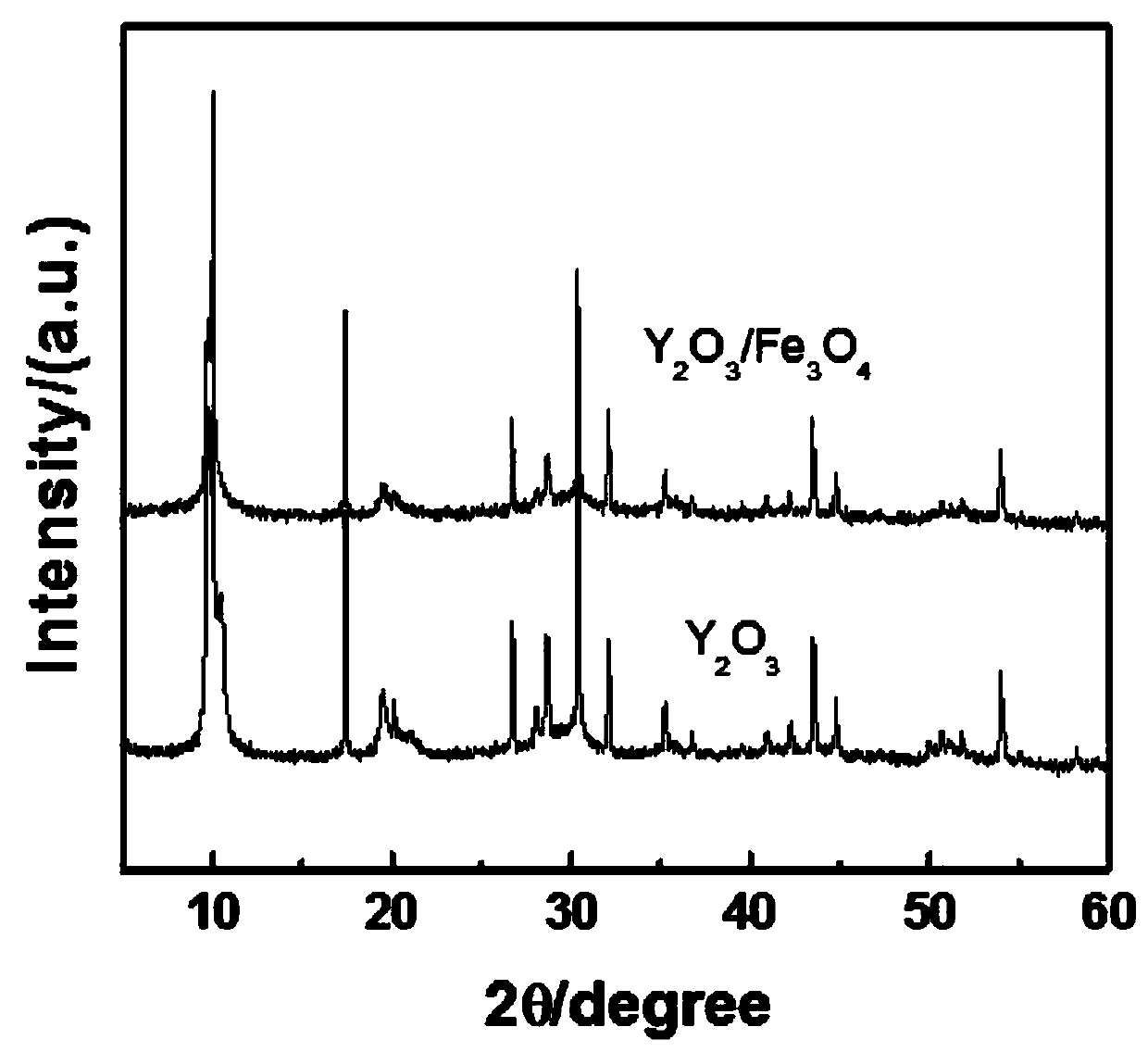

Preparation and Application of a Yttrium Oxide-Ferric Oxide Composite Nano Antibacterial Material

A technology of ferric tetroxide and nanomaterials, applied in the application, chemical instruments and methods, botanical equipment and methods, etc., can solve the problem of low utilization rate of visible light, achieve high potential industrial application value, excellent antibacterial performance, high The effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

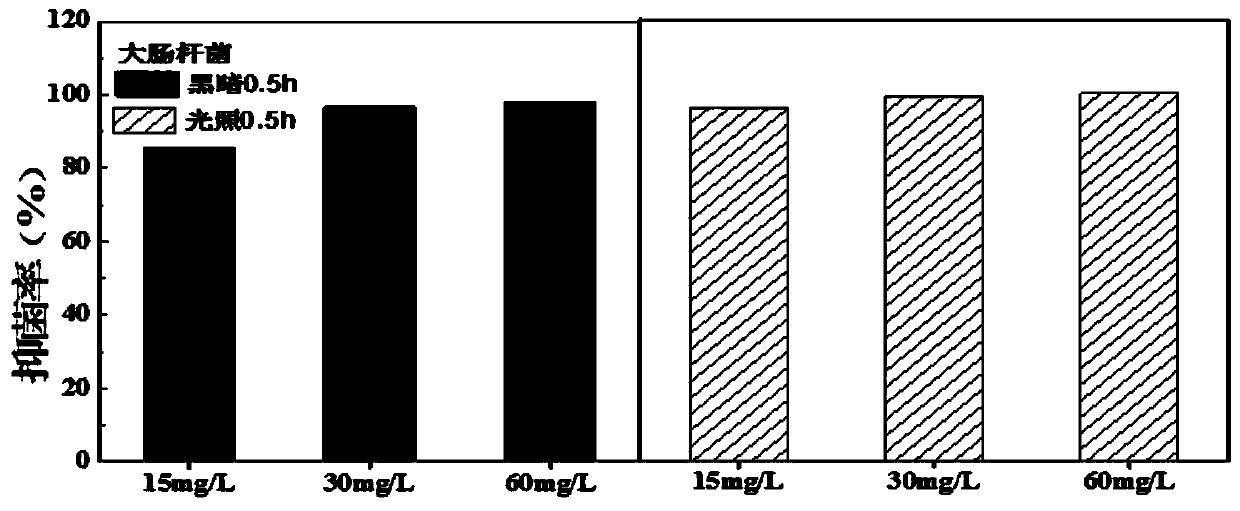

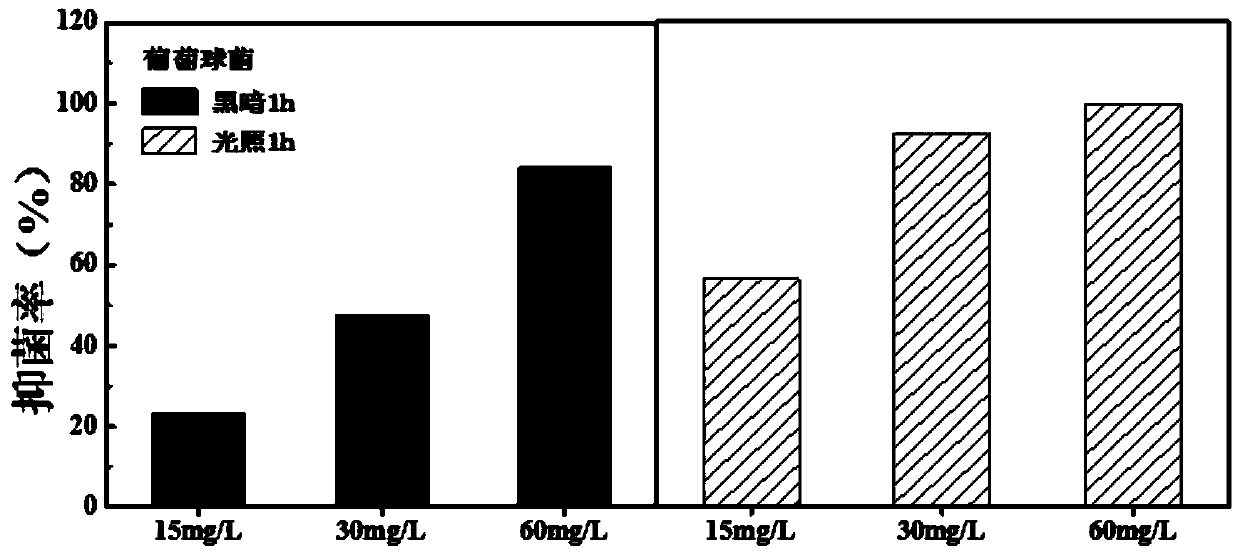

Embodiment 1

[0038] The preparation and application of a kind of yttrium oxide-ferric oxide composite nano antibacterial material of the present invention, comprises the following steps successively:

[0039] (1) Dissolve ferric chloride hexahydrate and ferrous dichloride tetrahydrate in deionized water at a molar ratio of Fe(III):Fe(II) of 2:1, and blow N into the solution. 2 30min for deoxygenation;

[0040] (2) Put the solution in a water bath at 60°C and keep N 2 Protect and vigorously stir for 5 minutes, then add 1-2mol / L NH 4 OH solution was slowly added to the solution until the pH was 8, then the solution was mixed and aged at 60°C for 30min;

[0041] (3) The precipitate in the solution is separated by an external magnetic force, and the supernatant is poured out. The precipitate was washed 4 times with deionized water, and then dried overnight at 40°C to obtain nano-ferric oxide;

[0042] ⑷ Weigh 1.552gY (NO 3 ) 3 ·6H 2 O, 0.5g of PVP and weighing 100mg of the product of s...

Embodiment 2

[0053] The preparation and application of a kind of yttrium oxide-ferric oxide composite nano antibacterial material of the present invention, comprises the following steps successively:

[0054] (1) Dissolve ferric chloride hexahydrate and ferrous dichloride tetrahydrate in deionized water at a molar ratio of Fe(III):Fe(II) of 2:1, and blow N into the solution. 2 30min for deoxygenation;

[0055] (2) Put the solution in a water bath at 60°C and keep N 2 Protect and vigorously stir for 5 minutes, then add 1-2mol / L NH 4 OH solution was slowly added to the solution until the pH was 8, then the solution was mixed and aged at 60°C for 30min;

[0056] (3) The precipitate in the solution is separated by an external magnetic force, and the supernatant is poured out. The precipitate was washed 4 times with deionized water, and then dried overnight at 40°C to obtain nano-ferric oxide;

[0057] ⑷ Weigh 1.552gY (NO 3 ) 3 ·6H 2 O, 0.5g of PVP and weighing 100mg of the product of s...

Embodiment 3

[0068] The preparation and application of a kind of yttrium oxide-ferric oxide composite nano antibacterial material of the present invention, comprises the following steps successively:

[0069] (1) Dissolve ferric chloride hexahydrate and ferrous dichloride tetrahydrate in deionized water at a molar ratio of Fe(III):Fe(II) of 2:1, and blow N into the solution. 2 30min for deoxygenation;

[0070] (2) Put the solution in a water bath at 60°C and keep N 2 Protect and vigorously stir for 5 minutes, then add 1-2mol / L NH 4 OH solution was slowly added to the solution until the pH was 8, then the solution was mixed and aged at 60°C for 30min;

[0071] (3) The precipitate in the solution is separated by an external magnetic force, and the supernatant is poured out. The precipitate was washed 4 times with deionized water, and then dried overnight at 40°C to obtain nano-ferric oxide;

[0072] ⑷ Weigh 1.552gY (NO 3 ) 3 ·6H 2 O, 0.5g of PVP and weighing 100mg of the product of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com