Method for preparing sulfurized fatty acid from kitchen waste oil

A technology of sulfurized fatty acid and waste oil, which is applied in the fields of fatty acid production, fat oil/fat refining, fatty acid preparation/refining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

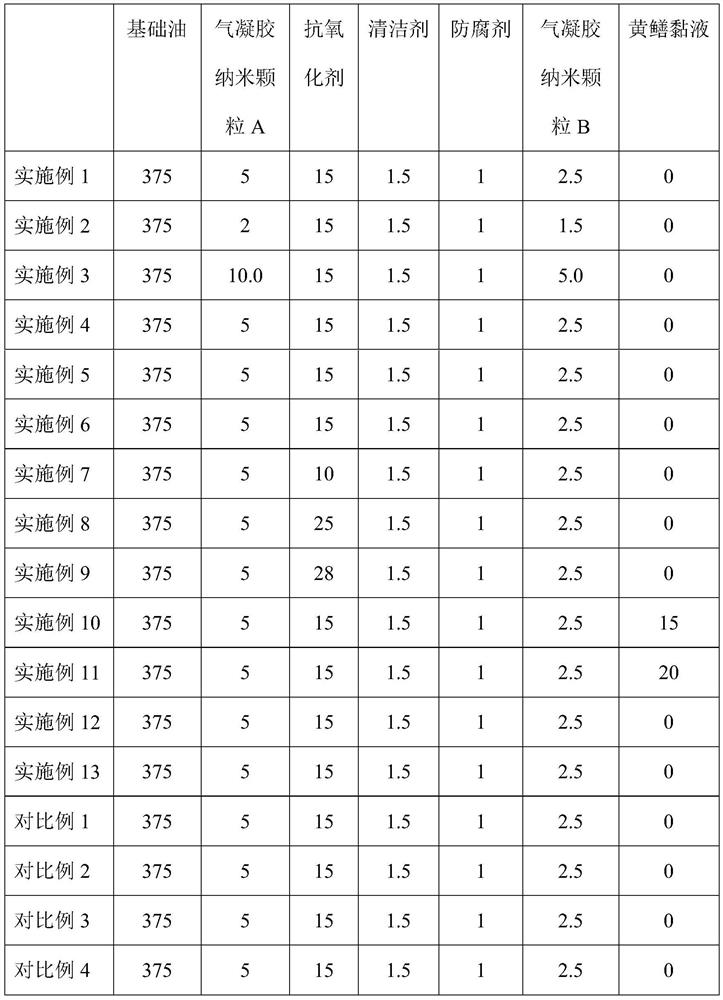

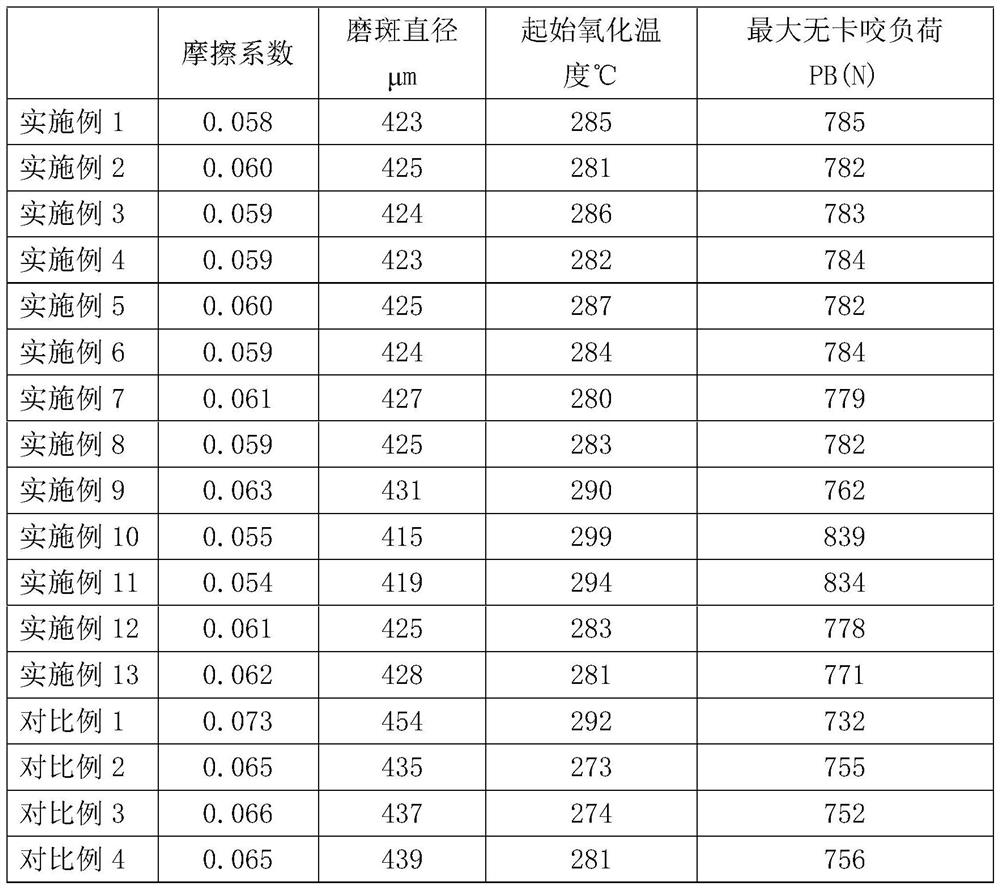

Embodiment 1

[0092] Step 1: Preparation of airgel nanoparticles A: 10 grams of cellulose nanofibers (1.56% by mass fraction) were mixed with deionized water, and ultrasonically treated for 8 minutes to obtain a nanoparticle dispersion. Triethoxysilane (KH-550) was added to KH-550 at a mass ratio of 1:1 to obtain a mixed solution. Stir the mixed solution at a speed of 650r / min for 2 hours at room temperature, freeze in liquid nitrogen for 40 minutes, and vacuum freeze-dry After 28 hours, put it into an oven and dry at 100° C. for 30 minutes to obtain KH-550 modified cellulose airgel nanoparticles.

[0093] Step 2: Preparation of airgel nanoparticles B: Mix 2 grams of cellulose nanofibers with deionized water, ultrasonically treat for 10 minutes to obtain a dispersion, add ethylenediaminetetraacetic acid (EDTA) aqueous solution, and stir at room temperature for 36 hours. Filtrate with suction, wash with ultrapure water several times, and dry at 90°C for 30 minutes to obtain EDTA-modified cel...

Embodiment 2

[0096] Except that the mass parts of KH-550 modified cellulose nanoparticles as airgel nanoparticles A in step 3 of Example 1 were replaced by 2 parts and EDTA modified cellulose as airgel nanoparticles B Except that the mass parts of the airgel nanoparticles were changed to 1.5 parts, the contents of other components and operating conditions were the same as those in Example 1.

Embodiment 3

[0098] Except that the mass parts of KH-550 modified cellulose nanoparticles as airgel nanoparticles A in step 3 of Example 1 were changed to 10 parts and EDTA modified cellulose as airgel nanoparticles B Except that the mass parts of the airgel nanoparticles were changed to 5 parts, the contents of other components and operating conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com