Ramp sheet resistance type metallized film evaporation device

A technology of metallized thin film and gradient square resistance, applied in vacuum evaporation plating, thin film/thick film capacitor, metal material coating process, etc., can solve the problem of overheating damage of organic thin film, thermal deformation of metallized thin film, and influence of thin film conduction effect and other issues to achieve the effect of improving uniformity and stability, ensuring electrical conductivity, and avoiding heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

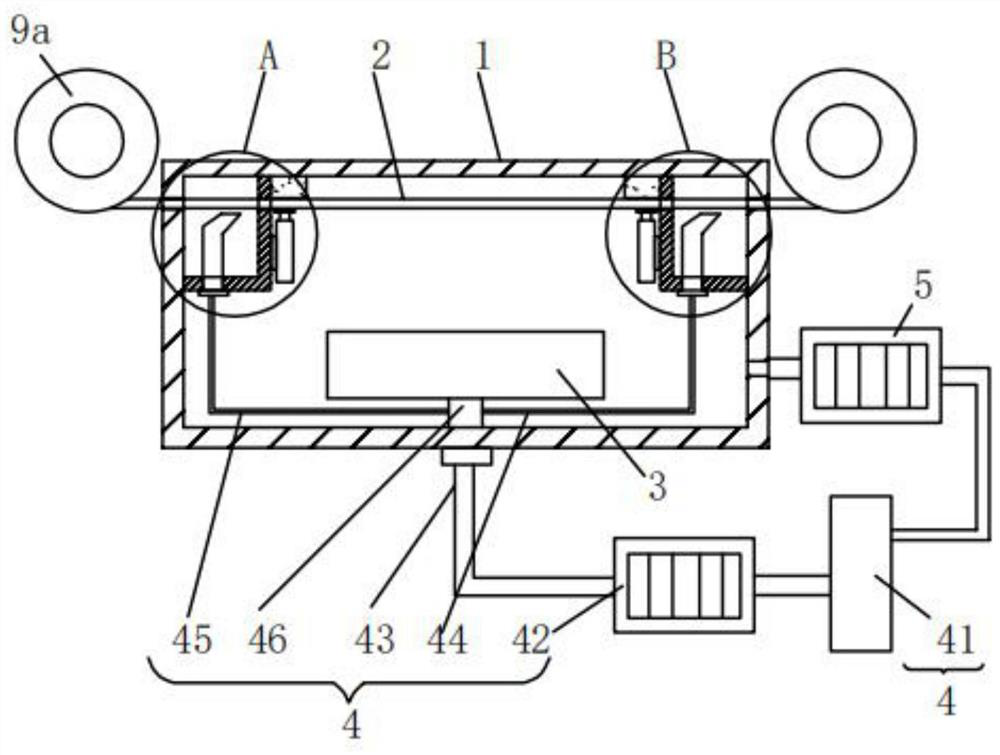

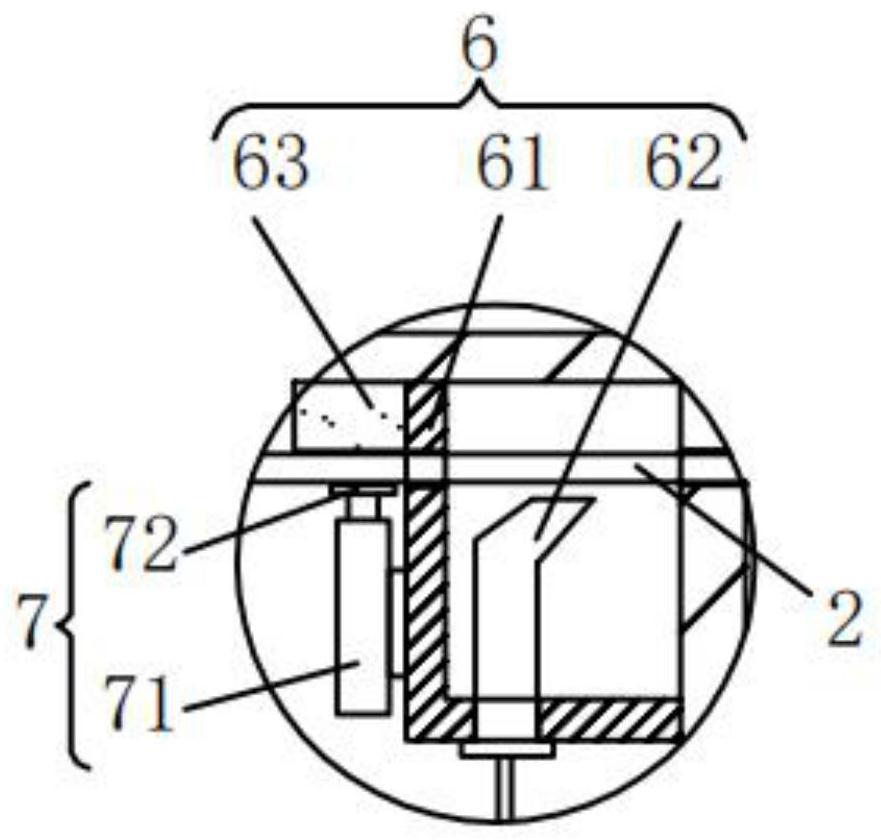

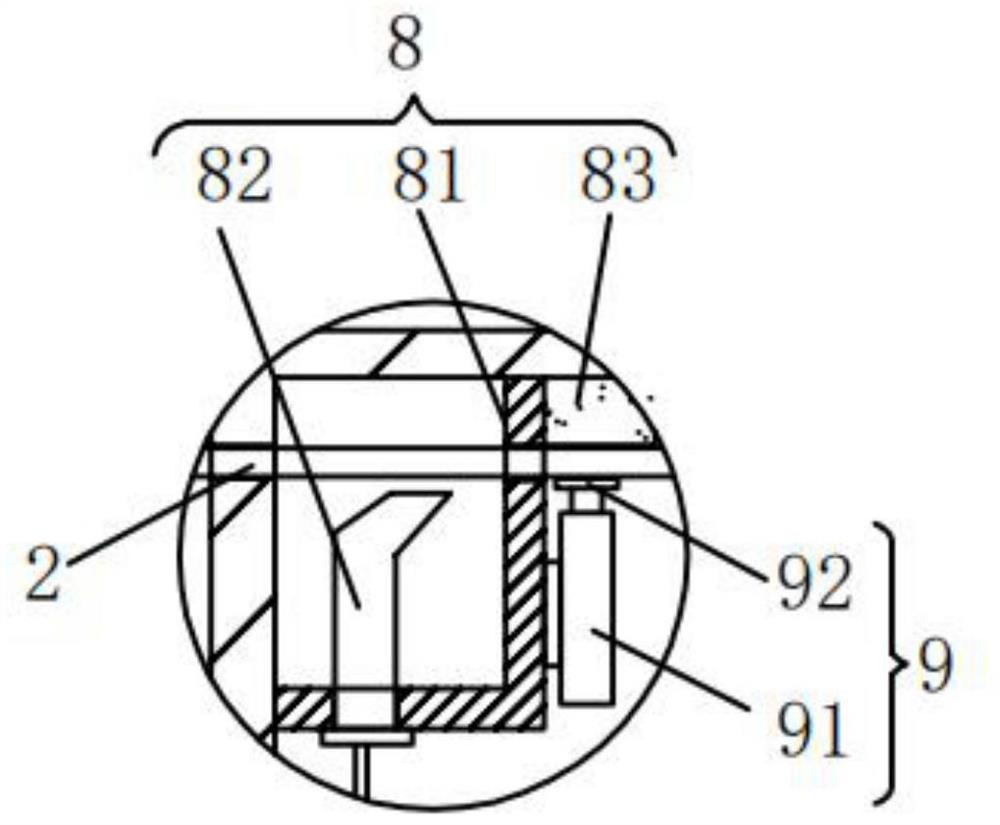

[0025] Gradient square resistance metallized film evaporation device, including a box body 1; a metal film main body 2 runs through the inner top of the box body 1, and the two ends of the metal film main body 2 are connected to a traction mechanism 9a; the traction mechanism 9a is used to drive The metal film main body 2 is continuously retracted, so that the metal film main body 2 moves continuously in the box body 1;

[0026] The side wall of the box body 1 communicates with the vacuum pump 5; the inner bottom of the box body 1 is equipped with an evaporation mechanism 3, and the evaporation mechanism 3 is horizontally p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com