Piezoresistive sensing fabric with one-way moisture conduction effect and preparation method thereof

A unidirectional moisture-conducting, conductive fabric technology, used in plant fibers, textiles and papermaking, fiber processing, etc., can solve problems such as poor wearing comfort and poor air permeability, and achieve high-humidity resistance performance, high precision, and excellent conductivity. , to ensure the effect of accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a piezoresistive sensing fabric with unidirectional moisture transfer function, comprising the following steps:

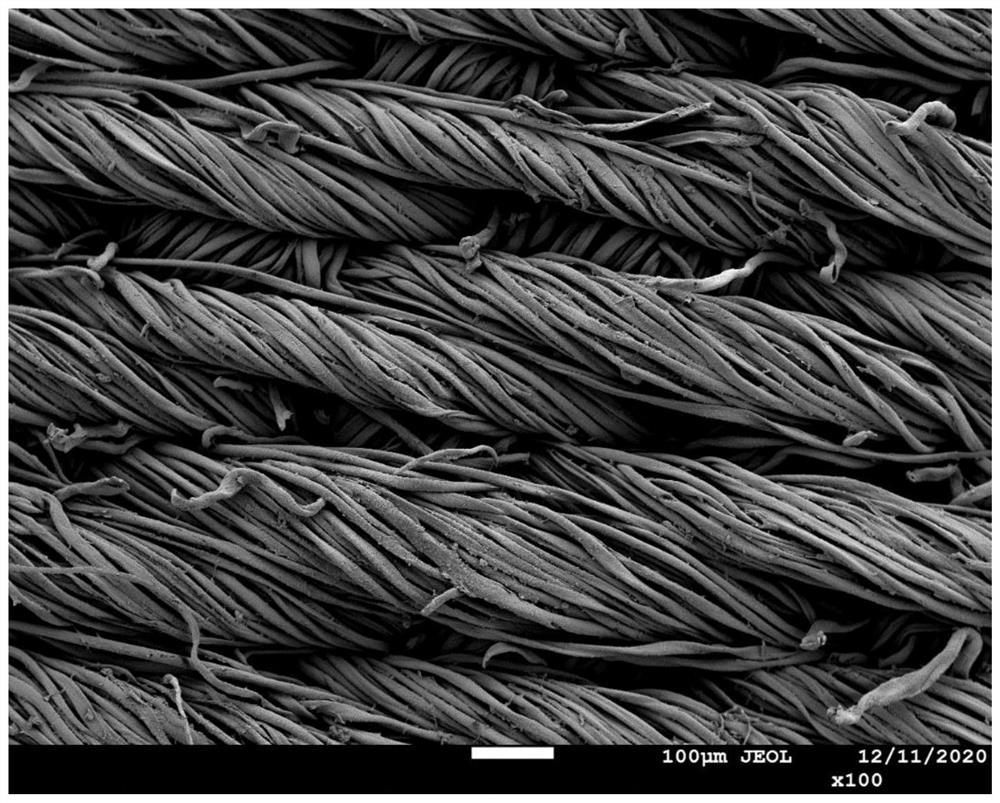

[0037] S1, immerse the pretreated fabric base cloth in the polymer conductive solution, and ultrasonically treat it for 1 to 30 minutes to obtain a conductive fabric, then roll the conductive fabric for 3 to 5 times, and then heat the conductive fabric at 50 to 120°C Drying for 5 to 60 minutes, so that the upper and lower surfaces and inside of the fabric base cloth are evenly deposited with a loaded polymer conductive layer to obtain the first conductive fabric;

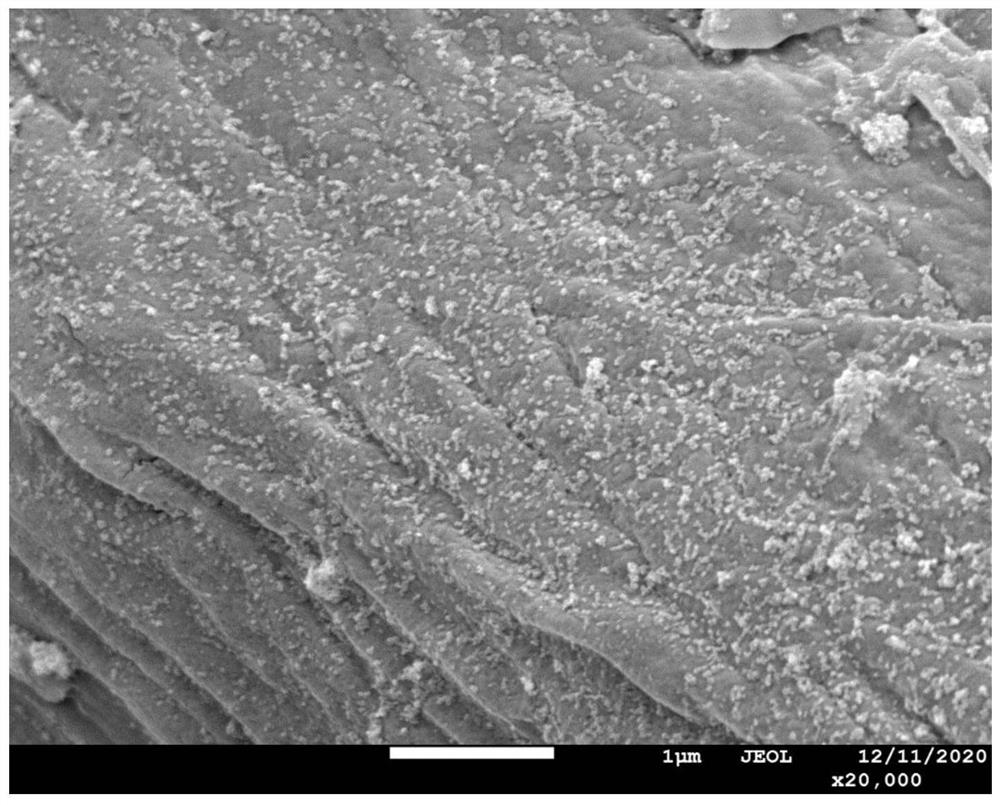

[0038] S2, immersing the first conductive fabric prepared in step S1 in a hydrophobic metal oxide dispersion, and ultrasonically treating it for 0.5-15 minutes to obtain a hydrophobic conductive fabric; then washing the hydrophobic conductive fabric, and then drying at 50-120°C for 5-60 minutes, so that a hydrophobic metal oxide layer is evenly deposit...

Embodiment 1

[0049] A preparation method of a piezoresistive sensing fabric with unidirectional moisture transfer, comprising the steps of:

[0050] S1, put the cotton fabric base cloth in water, sodium hydroxide solution, and ethanol in sequence, ultrasonically clean it for 5 minutes, and then dry it naturally. solution, sonicated for 10 minutes to obtain a conductive fabric, and then the conductive fabric was subjected to rolling treatment, repeated 3 times, and then dried at 60°C for 15 minutes, so that the upper and lower surfaces and interior of the fabric base cloth had a high uniform deposition load. Molecular conductive layer to obtain the first conductive fabric;

[0051] S2, immersing the first conductive fabric prepared in step S1 in a dispersion of hydrophobic titanium dioxide with a concentration of 5 mg / mL, and ultrasonically treating it for 1.5 min to obtain a hydrophobic conductive fabric; then washing the hydrophobic conductive fabric , and then dried at 60° C. for 15 min...

Embodiment 2-4

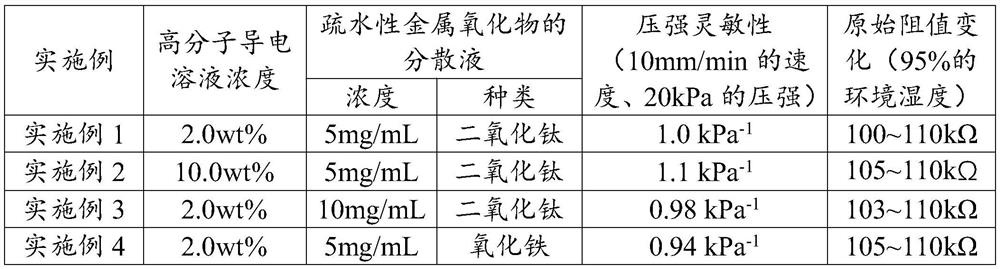

[0085] The difference from Example 1 lies in that: the settings of various implementation parameters in the preparation steps are different, and other steps are the same as in Example 1, and will not be repeated here.

[0086] Table 1 is the parameter setting in embodiment 1 to 4

[0087]

[0088] Combined with Table 1 for analysis:

[0089] 1) In the present invention, the impact of the polymer conductive solution concentration on the piezoresistive sensing weaving sensing performance is: with the increase of the conductive solution concentration, the resistance of the piezoresistive sensing fabric decreases in a small range, and the sensing Sensitivity has been slightly increased. In view of the cost factor, good sensing performance can be achieved by selecting a moderate concentration of the conductive solution.

[0090] 2) The concentration and type of the dispersion liquid of the hydrophobic metal oxide have an effect on the sensing performance of the piezoresistive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com