Liquid crystal reinforced ultra-high molecular weight polyethylene lithium battery diaphragm and preparation method thereof

A technology of ultra-high molecular weight and lithium battery diaphragm, which is applied to battery pack parts, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A liquid crystal reinforced ultra-high molecular weight polyethylene lithium battery diaphragm, which weighs the following components in weight percentage: ultra-high molecular weight polyethylene 75wt%, ultra-high molecular weight polyethylene graft material 5wt%, liquid crystal polymer 20wt%;

[0035] Wherein, the average molecular weight of the ultra-high molecular weight polyethylene is greater than 2 million;

[0036] Wherein, the ultra-high molecular weight polyethylene grafting material contains glycidyl methacrylate (GMA) functional group on the molecular chain, and the specific preparation method is as follows step (2);

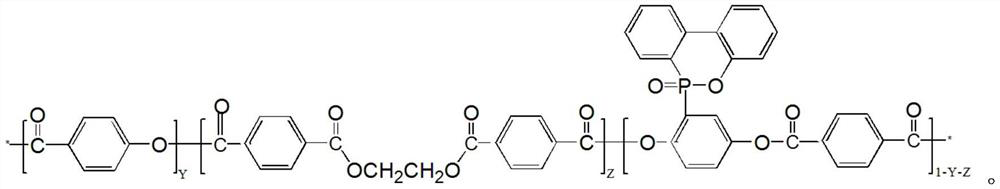

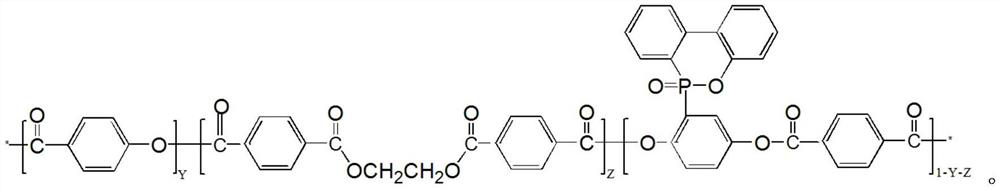

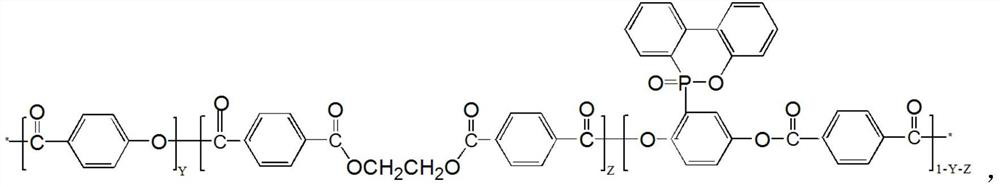

[0037] Wherein, the melting point of the liquid crystal polymer is 185°C to 205°C, and the structure of the liquid crystal polymer is:

[0038]

[0039] Among them, Y, Z, and 1-Y-Z represent the overall composition rather than the chain length, and the content of Y and Z is related to the number of moles of raw materials added.

[0040] Pr...

Embodiment 2

[0047] A liquid crystal reinforced ultra-high molecular weight polyethylene lithium battery diaphragm, which weighs the following components in weight percentage: ultra-high molecular weight polyethylene 70wt%, ultra-high molecular weight polyethylene graft material 10wt%; liquid crystal polymer 20wt%.

[0048] In this example, a liquid crystal reinforced ultra-high molecular weight polyethylene lithium battery separator was prepared according to the same technical method as in Example 1.

Embodiment 3

[0050] A liquid crystal reinforced ultra-high molecular weight polyethylene lithium battery diaphragm, which weighs the following components in weight percent: ultra-high molecular weight polyethylene 65 wt%, ultra-high molecular weight polyethylene graft material 15 wt%; liquid crystal polymer 20 wt%.

[0051] In this example, a liquid crystal reinforced ultra-high molecular weight polyethylene lithium battery separator was prepared according to the same technical method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com