Anti-blocking industrial sewage treatment device

A treatment device and industrial sewage technology, applied in grain treatment, fixed filter element filter, filtration and separation, etc., can solve problems such as easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

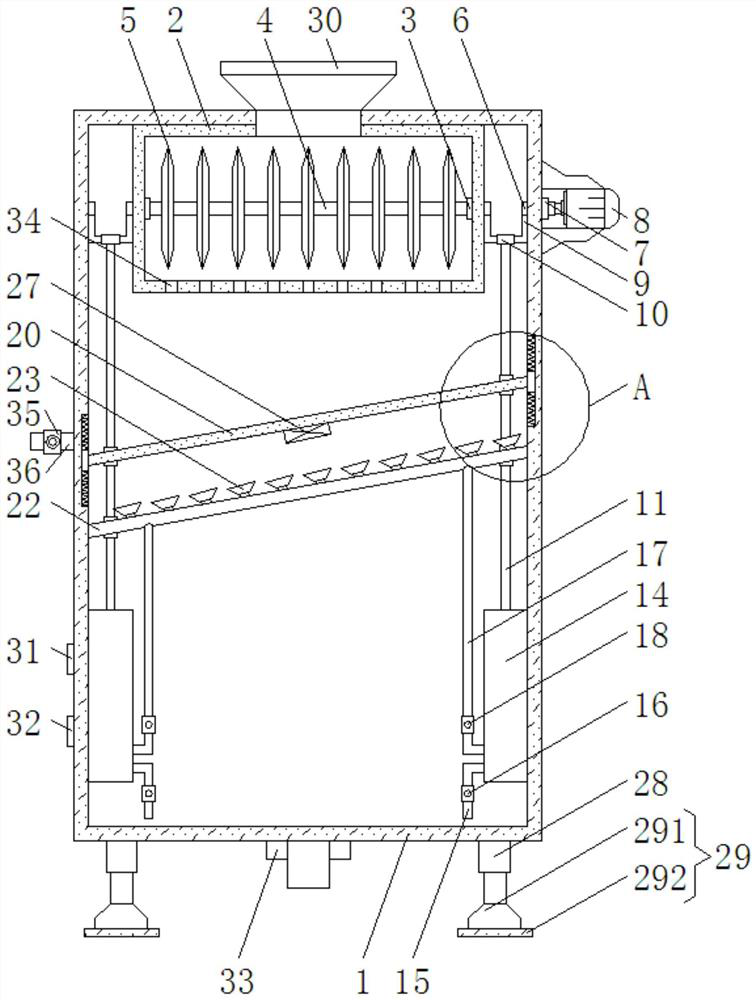

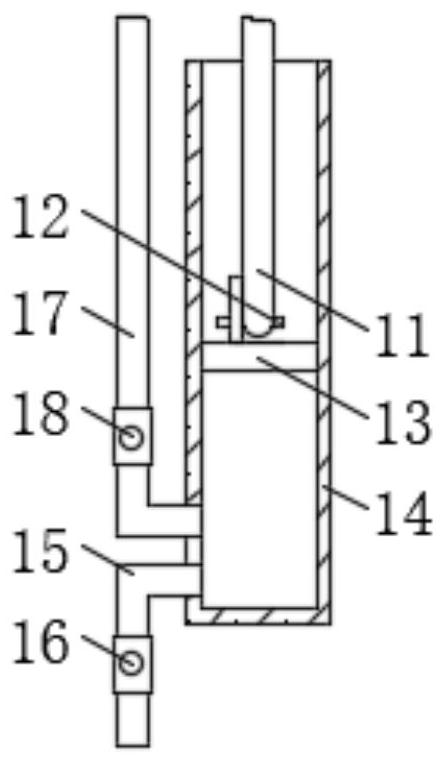

[0044] Such as Figure 1 to Figure 6 As shown, the present invention discloses an anti-blocking industrial sewage treatment device, comprising a sewage treatment tank 1 and a filter plate 20 built in the sewage treatment tank; the top of the sewage treatment tank 1 is provided with a sewage treatment tank sewage inlet, which It is characterized in that: the anti-blocking industrial sewage treatment device also includes a reamer mechanism located in the space between the sewage inlet of the treatment tank and the filter plate 20, the reamer mechanism includes a reamer box 2 and a reamer 5; the reamer Knife 5 is fixed on the rotating shaft 4, and the first end of this rotating shaft 4 is connected the transmission shaft of motor 8 through transmission mechanism, and described rotating shaft 4 is installed in the crushing box 2 by two first bearings 3; The top is provided with the sewage inlet of the crushing tank which is connected to the sewage inlet of the treatment tank, and ...

Embodiment approach

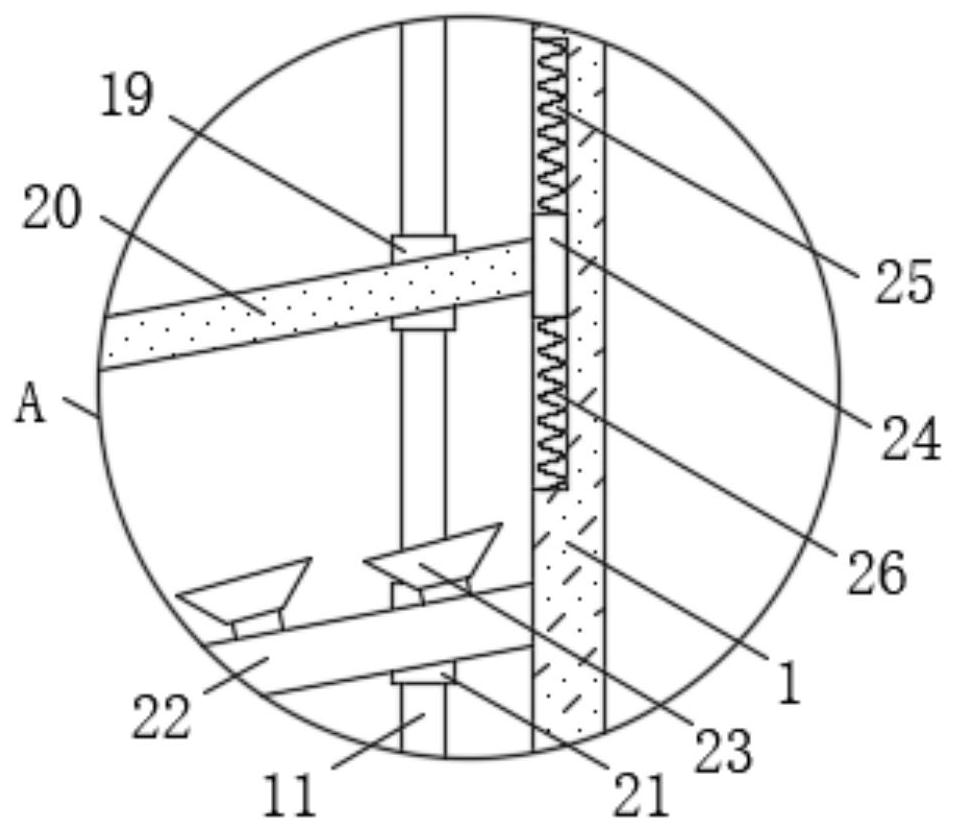

[0052] The anti-blocking type industrial sewage treatment device also includes a cleaning mechanism and a water inlet mechanism for cleaning the filter plate 20, the cleaning mechanism includes a sub-fluid 22 located below the filter plate 20, and the top surface of the sub-fluid 22 is A plurality of spray heads 23 arranged towards the filter plate 20 are installed, and the water inlet mechanism can suck the sewage in the sewage treatment tank 1 and supply it to each of the spray heads 23 through the dividing fluid 22 .

[0053] Thus, while the filter plate 20 is filtering the sewage, the nozzle 23 can also spray the filtered sewage onto the filter plate 20 to realize self-cleaning and further prevent the filter plate 20 from performing sewage filtration treatment. In the event of accidental clogging in the process, to further improve the treatment capacity of the filter plate 20 for sewage per unit time.

[0054] Preferably: the opening direction of the filter holes of the fi...

Embodiment 3

[0062] On the basis of the above-mentioned embodiment two, the present embodiment three also adopts the following preferred implementation modes:

[0063] An exciter 27 is arranged on the filter plate 20 .

[0064] Thereby, when cleaning mechanism carries out self-cleaning to filter plate 20, can also start vibrator 27, utilize vibrator 27 to vibrate filter plate 20, the impurity in the filter hole of filter plate 20 is loosened, to improve cleaning mechanism. The flushing effect of the sprayed high-pressure water on the filter plate 20.

[0065] The above is the basic implementation of the third embodiment, further optimization, improvement and limitation can be done on the basis of the basic implementation:

[0066] Preferably: the two sides of the filter plate 20 are fixedly connected with sliders 24, and the two sidewalls inside the sewage treatment tank 1 are respectively provided with a chute 25 extending along the upper limit corresponding to the two sliders 24; The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com