Seafood bean curd and manufacture technology thereof

A production process and technology of tofu, applied in the field of food processing, can solve the problems such as the inability to meet the individual consumption and dietary needs of consumers, the dull taste of tofu, and consumer allergies, so as to achieve rich taste, convenient consumption and high nutritional value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

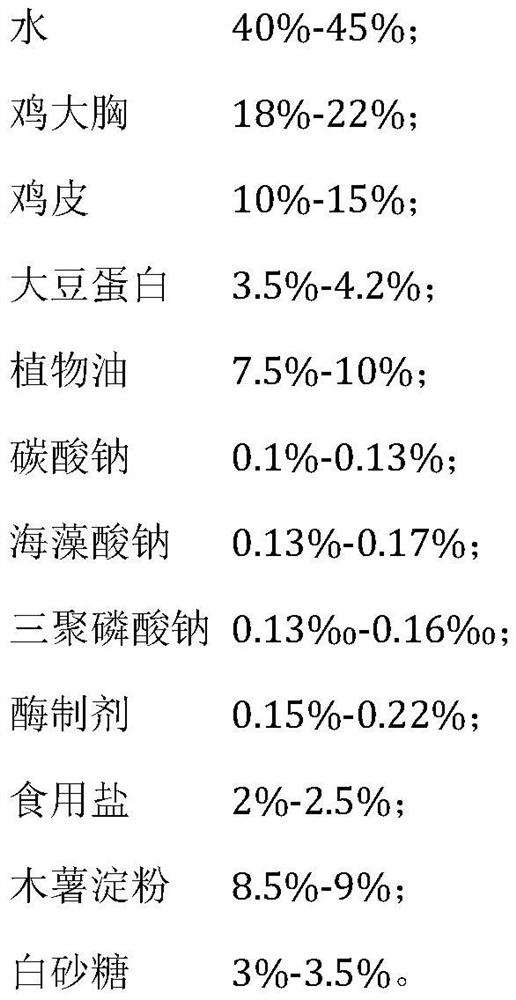

[0036] This embodiment relates to a seafood tofu, which comprises the following raw materials in proportion by weight:

[0037] Water 41%, chicken breast 17.1%; chicken skin 15%; soybean protein 3.5%; vegetable oil 7.5%; sodium carbonate 0.1%; sodium alginate 0.13%; sodium tripolyphosphate 0.15‰; enzyme preparation 0.155%; edible salt 2% ; Tapioca starch 10.5%; White sugar 3%.

[0038] The present embodiment relates to the manufacturing process of above-mentioned seafood bean curd, comprises the following steps:

[0039] Preparation of white meat granules: Add chicken skin, sodium alginate, sodium tripolyphosphate and water accounting for 10% by weight of the total material into a chopping machine and mix evenly at a speed of 3500r / min. In the container, stand at 5°C for 5.5 hours, then shred and dice into 5mm*5mm*5mm for later use;

[0040] Preparation of emulsified slurry B: Mix soybean protein and the remaining water, mix at a slow speed of 1000r / min for 1min at 10°C, the...

Embodiment 2

[0045] This embodiment relates to a seafood tofu, which comprises the following raw materials in proportion by weight:

[0046] Water 40%, chicken breast 20%; chicken skin 10.1%; soybean protein 4.0%; vegetable oil 8.2%; sodium carbonate 0.12%; sodium alginate 0.155%; sodium tripolyphosphate 0.15‰; enzyme preparation 0.21%; edible salt 2% ; Tapioca starch 12%; White sugar 3.2%.

[0047] The present embodiment relates to the manufacturing process of above-mentioned seafood bean curd, comprises the following steps:

[0048] Preparation of white meat granules: Add chicken skin, sodium alginate, sodium tripolyphosphate and water accounting for 8% by weight of the total material into a chopping machine and mix evenly at a speed of 3000r / min. In the container, let stand at 2°C for 5.5 hours, then shred and dice into 5mm*5mm*5mm for later use;

[0049] B. Preparation of emulsified slurry: Mix soybean protein and the remaining water, and mix at 6°C at a slow speed of 800r / min for 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com