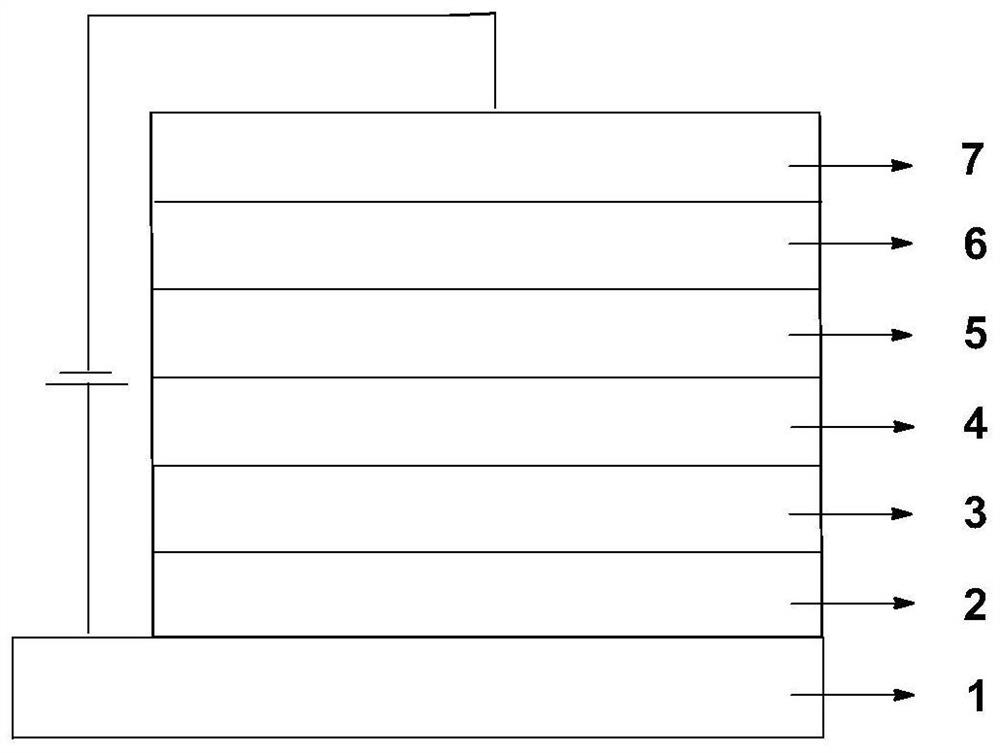

Organic electroluminescent material and application thereof

An electroluminescent material and luminescent technology, applied in luminescent materials, organic chemistry, circuits, etc., can solve the problems of unable to meet the needs of high-generation OLED production lines, unstable film state, greenish color, etc., to achieve good film Good stability, good device efficiency, and low lighting voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 compound C01

[0040]

[0041] In a 250mL three-neck flask, add CBDA (3.9g, 0.02mol), boronamine intermediate A (15.9g, 0.04mol), propionic acid (120g), and the system is slowly heated to 100-120°C under nitrogen protection. After 24 hours of heat preservation reaction, off-white solid powder precipitated out of the reaction system. The system was cooled to room temperature, and filtered with suction to obtain a white filter cake. Use 100g of tetrahydrofuran to heat and dissolve the filter cake, and the obtained solution is quickly passed through a 15cm thick silica gel column, and the column liquid is desolventized to obtain a white solid crude product, which is recrystallized and purified by using toluene:petroleum ether=1:2, cooled, filtered and dried to obtain Compound C01, white solid 14.7g, yield 77.0%.

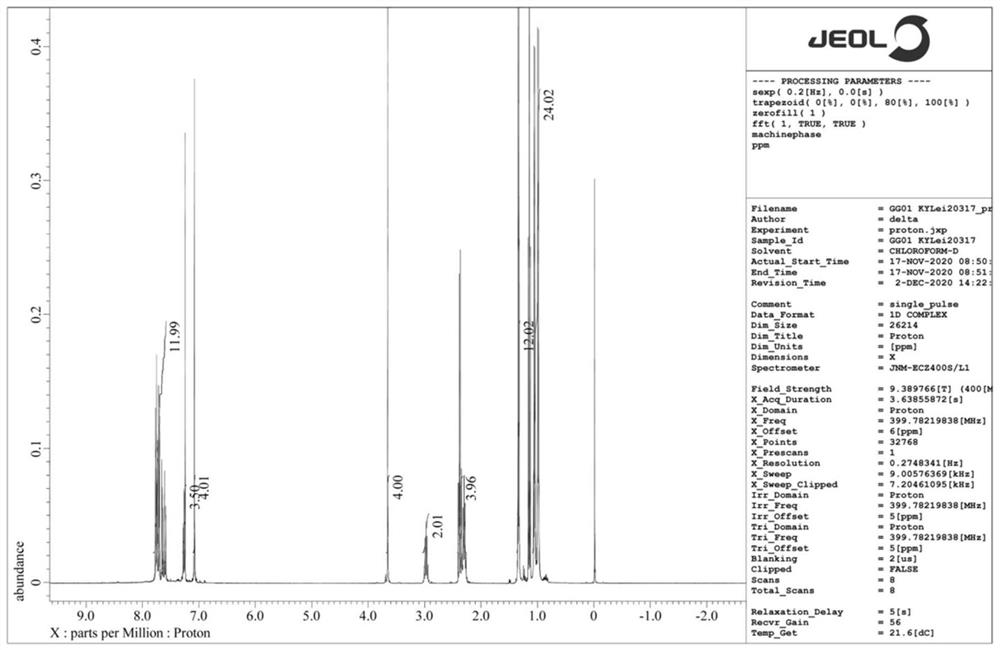

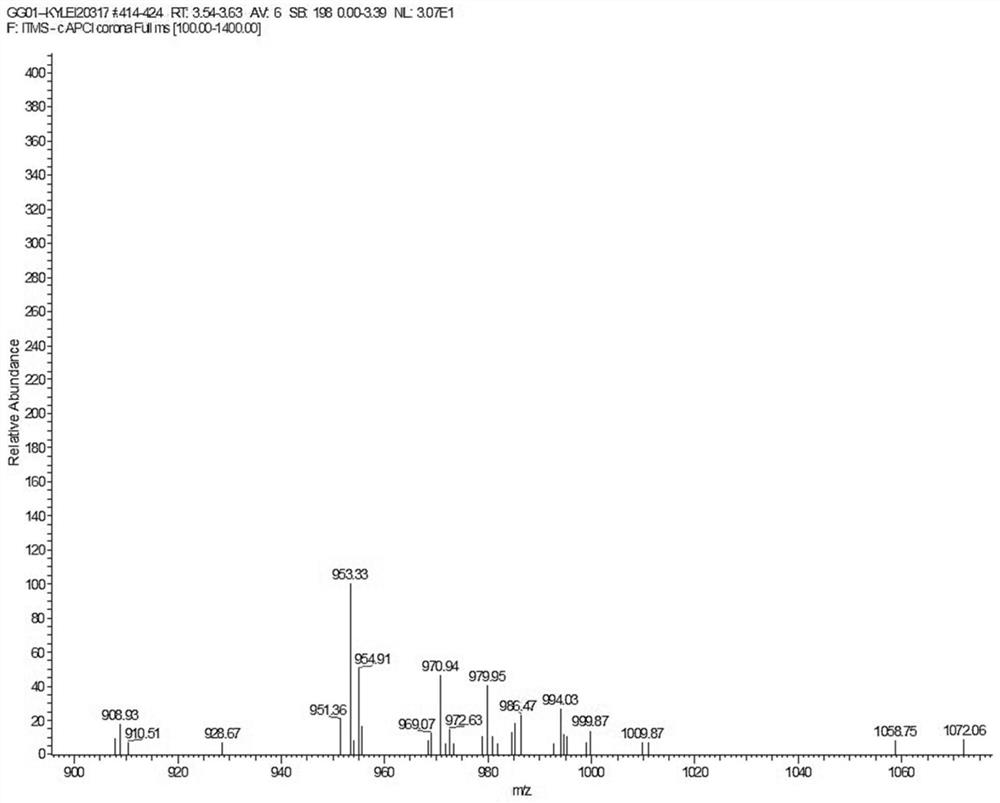

[0042] Mass spectrometry, APCI source, negative ion mode, molecular formula C 62 h 64 B 2 N 2 o 6 , the theoretical val...

Embodiment 2

[0043] The preparation of embodiment 2 compound C02

[0044]

[0045] According to the method described in Example 1 (preparation of compound C01), boronamine intermediate B (12.5g, 0.04mol) was dropped in to replace boronamine intermediate A (15.9g, 0.04mol) to obtain compound C02, white solid 10.0g , yield 63.6%.

[0046] Mass spectrometry, APCI source, negative ion mode, molecular formula C 50 h 40 B 2 N 2 o 6 , the theoretical value is 786.31, and the test value is 785.18. Elemental analysis (C50 h 40 B 2 N 2 o 6 ), theoretical value C: 76.36, H: 5.13, O: 12.20, measured value C: 76.31, H: 5.18, O: 12.22.

Embodiment 3

[0047] The preparation of embodiment 3 compound C07

[0048]

[0049] According to the method described in Example 1 (preparation of compound C01), DMCBDA (4.5 g, 0.02 mol) was added instead of CBDA (3.9 g, 0.02 mol) to obtain compound C07, 15.7 g of white solid, yield 79.9%.

[0050] Mass spectrometry, APCI source, negative ion mode, molecular formula C 64 h 68 B 2 N 2 o 6 , the theoretical value is 982.53, and the test value is 981.44. Elemental analysis (C 64 h 68 B 2 N 2 o 6 ), theoretical value C: 78.21, H: 6.97, O: 9.77, measured value C: 78.27, H: 6.91, O: 9.72.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com