Photochromic composition, product and preparation method of hyperbranched polyurethane vinyl ether

A technology of polyurethane vinyl ether and photochromism, which is applied in the field of optical films, can solve the problems of high cost burden, waste of color changing powder, and inability to prepare high value-added lenses, and achieve the effect of increasing crosslinking density and improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

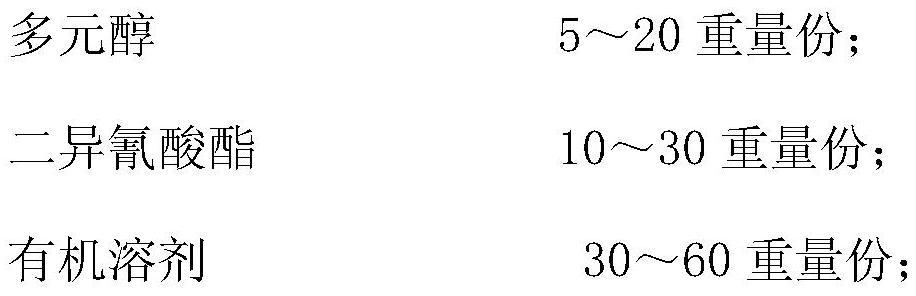

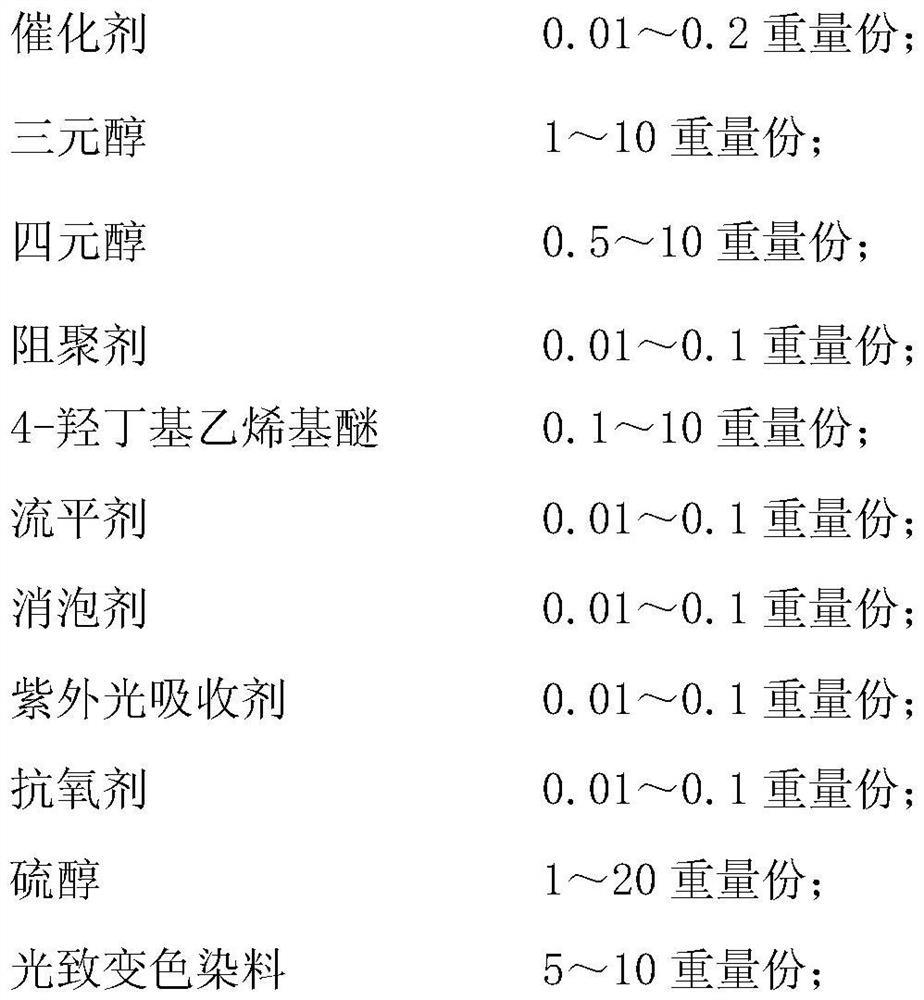

Method used

Image

Examples

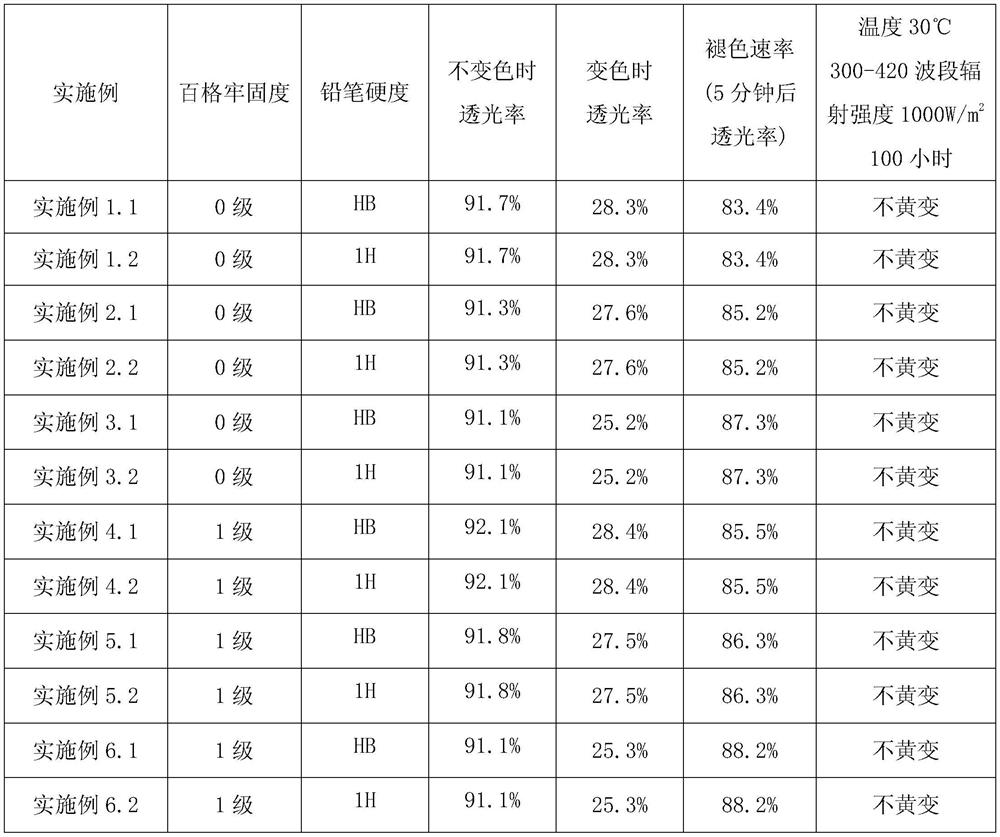

Embodiment 11

[0044]Add 10g PEG400 to the container, vacuumize at 120°C for 1 hour, cool down to 60°C, add 16.67g IPDI, 55g ethyl acetate and 0.2g DBTDL, heat up to 70°C and keep stirring for 2 hours, cool down to 60°C, slowly drop 1.02g glycerol, heat up to 70°C and keep stirring for 2 hours, cool down to 60°C, slowly add 0.76g pentaerythritol dropwise, heat up to 70°C and keep stirring for 2 hours, test that the NCO content is 2.25%, add 0.02g MEHQ and 5.2g 4-Hydroxybutyl vinyl ether, heat up to 80°C and keep stirring for 2 hours, then add 3.5g midnight gray and 3.5g misty gray, heat up to 90°C and keep stirring for 1 hour, finally add 0.1g BYK1790, 0.1g BYK333, 5.46g PETMP , 0.02gBHT, 0.02g Tinuvin 329, mixed uniformly to obtain a photochromic composition of hyperbranched polyurethane vinyl ether, the refractive index is 1.554. Spray the photochromic coating composition on the surface of the PC lens, rotate at 800rpm for 20 seconds, and then irradiate with a 300W infrared lamp for 2 minu...

Embodiment 12

[0046] Add 10g PEG400 to the container, vacuumize at 120°C for 2 hours, cool down to 60°C, add 16.67g IPDI, 55g ethyl acetate and 0.2g DBTDL, heat up to 70°C and keep stirring for 2 hours, cool down to 60°C, slowly drop 1.02g glycerol, heat up to 70°C and keep stirring for 2 hours, cool down to 60°C, slowly add 0.76g pentaerythritol dropwise, heat up to 70°C and keep stirring for 2 hours, test that the NCO content is 2.25%, add 0.02g MEHQ and 5.2g 4-Hydroxybutyl vinyl ether, heat up to 80°C and keep stirring for 2 hours, then add 3.5g midnight gray and 3.5g misty gray, heat up to 90°C and keep stirring for 1 hour, finally add 0.1g BYK1790, 0.1g BYK333, 5.46g PETMP , 0.02gBHT, 0.02g Tinuvin 329, mixed uniformly to obtain a photochromic composition of hyperbranched polyurethane vinyl ether, the refractive index is 1.554. Spray the photochromic coating composition on the surface of the PC lens, rotate at 800rpm for 20 seconds, and then irradiate with a 300W infrared lamp for 2 mi...

Embodiment 21

[0049] Add 10g PEG600 to the container, vacuumize at 120°C for 1 hour, cool down to 60°C, add 16.67g IPDI, 51.2g ethyl acetate and 0.2g DBTDL, heat up to 70°C and keep stirring for 2 hours, cool down to 60°C, slowly Add 1.19g of glycerol dropwise, heat up to 70°C and keep stirring for 2 hours, cool down to 60°C, slowly add 0.66 pentaerythritol dropwise, heat up to 70°C and keep stirring for 2 hours, test that the NCO content is 3.0%, add 0.02g MEHQ and 6.79 g 4-hydroxybutyl vinyl ether, heat up to 80°C and keep stirring for 2 hours, then add 3.5g midnight gray and 3.5g misty gray, heat up to 90°C and keep stirring for 1 hour, finally add 0.1g BYK1790, 0.1g BYK333, 6.5 gPETMP, 0.02gBHT, and 0.02g Tinuvin 329 were uniformly mixed to obtain a photochromic composition of hyperbranched polyurethane vinyl ether, with a refractive index of 1.554. Spray the photochromic coating composition on the surface of the PC lens, rotate at 800rpm for 20 seconds, and then irradiate with a 300W i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com