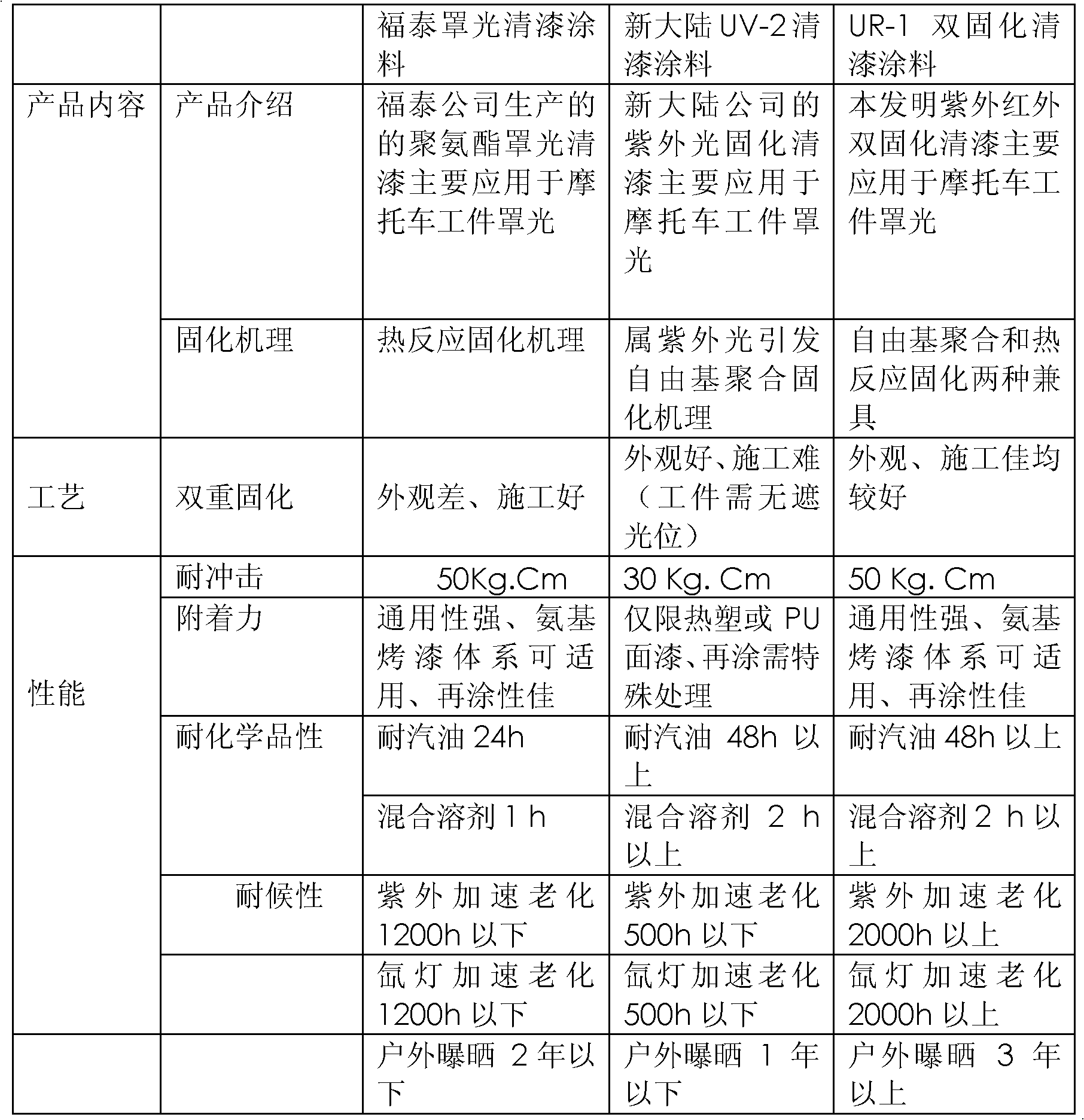

Ultraviolet-infrared double curing varnish coating and preparation method thereof

A dual-curing varnish, dual-curing technology, used in coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc., can solve the limitations of UV curing technology application and promotion, yellowing of protruding parts, large residual stress, etc. To improve long-term weather resistance and insufficient curing, reduce the content of residual photoinitiator and unreacted double bonds, and improve the conversion rate of double bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of UR-1 dual-curing varnish: take 25g trifunctional aliphatic urethane acrylate oligomer (U680H of German BAYER company), 15g bifunctional aliphatic urethane acrylate oligomer (SARTOMER company CN965), 30g hydroxyl-containing Acrylate oligomer (Deqian M7), 15g of monomer A (3g of 1,6-ethylene glycol diacrylate and 12g of tripropylene glycol diacrylate mixture) was put into operation kettle A, and dispersed for 5 minutes at 1000RPM, Then add 2g compound free radical initiator (mixture of 1g α-hydroxy ketone initiator and 1g 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide initiator), 3g rheological modifier (1.5g dimethyl Base siloxane and 1.5g lauryl acrylate mixture), 10g of the first solvent (4g butyl ester, 3g toluene, 3g propylene glycol methyl ether acetate mixture) was added to the operation kettle B, and dispersed at 500RPM for 5 minutes. Add the mixture of working kettle B into working kettle A (300RPM) while dispersing, and then disperse at 1000...

Embodiment 2

[0042] Preparation of UR-1 dual-cure varnish: take 20g trifunctional aliphatic urethane acrylate oligomer (U680H of German BAYER company), 20g bifunctional aliphatic urethane acrylate oligomer (SARTOMER company CN965), 30g hydroxyl-containing Acrylate oligomer (Deqian M7), 10g of monomer A (3g of 1,6-ethylene glycol diacrylate and 12g of tripropylene glycol diacrylate mixture) was put into operation kettle A, and dispersed for 5 minutes at 1000RPM, Then 1.5g composite free radical initiator (0.8g α-hydroxy ketone initiator and 0.7g2,4,6 (trimethylbenzoyl) diphenylphosphine oxide initiator mixture), 3.5g rheological modifier ( A mixture of 1.5g dimethylsiloxane and 2g hydroxyethyl acrylate), 20g of the first solvent (a mixture of 8g butyl ester, 6g toluene, and 6g propylene glycol methyl ether acetate) were added to the operation kettle B, and dispersed at 500RPM for 5 minutes. Add the mixture of working kettle B into working kettle A (300RPM) while dispersing, and then dispers...

Embodiment 3

[0053] The preparation of UR-1 dual-curing varnish: take 15g trifunctional aliphatic urethane acrylate oligomer (U680H of German BAYER company), 25g bifunctional aliphatic urethane acrylate oligomer (SARTOMER company CN965), 30g hydroxyl-containing Acrylate oligomer (Deqian M7), 20g of monomer A (a mixture of 8g of 1,6-ethylene glycol diacrylate and 12g of tripropylene glycol diacrylate) was put into operation kettle A, dispersed at 1000RPM for 5 minutes, Then add 2g compound free radical initiator (mixture of 1g α-hydroxy ketone initiator and 1g 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide initiator), 3g rheological modifier (1.5g dimethyl Base siloxane and 1.5g hydroxypropyl acrylate mixture), 15g of the first solvent (3g butyl ester, 6g toluene, 6g propylene glycol methyl ether acetate mixture) was added to the operation kettle B, and dispersed at 500RPM for 5 minutes. Add the mixture of working kettle B into working kettle A (300RPM) while dispersing, and then disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com