Inductive energy storage type temperature sensor

A temperature sensor and energy storage technology, applied in thermometers, thermometer applications, instruments, etc., can solve the problem of inability to quickly locate the fault location, high labor intensity of electric workers, and failure to achieve the degree of deterioration and operating status of key parts of electrical equipment Real-time monitoring and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

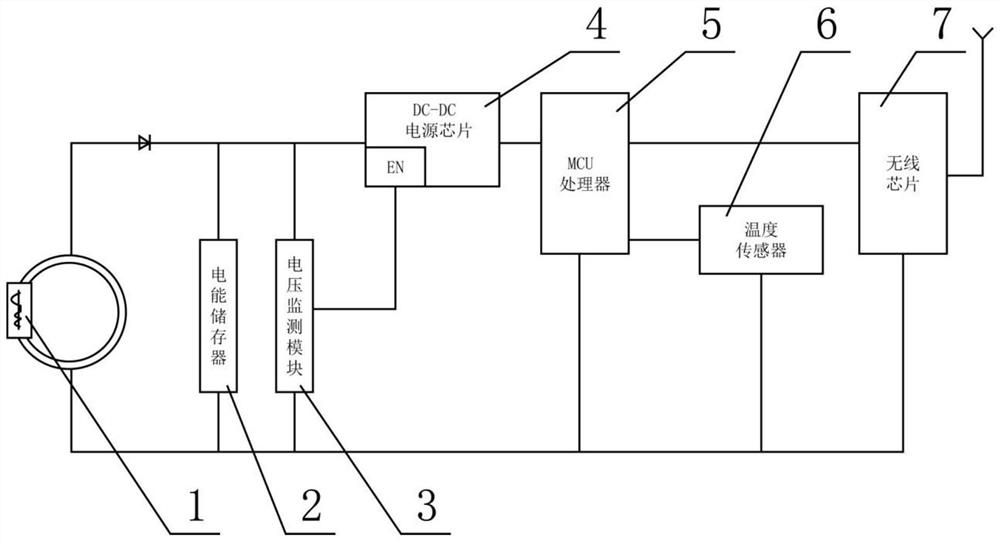

[0027] The embodiment of the present invention discloses an inductive energy storage temperature sensor, such as figure 1 , 4 , 5, including energy sensing module 1, electric energy storage 2, voltage monitoring module 3, DC-DC power supply chip 4, MCU processor 5, temperature sensor 6 and wireless chip 7, the energy sensing module 1 through the diode and The electric energy storage 2 is connected, the electric energy storage 2 adopts a capacitor, the electric energy storage 2 is connected to the voltage monitoring module 3, and the voltage monitoring module 3 is connected to the DC-DC power supply chip 4, so The DC-DC power supply chip 4 supplies power to the MCU processor 5, the temperature sensor 6 and the wireless chip 7, and the MCU processor 5 is connected to the temperature sensor 6 and the wireless chip 7. The input voltage of the DC-DC power supply chip 4 is 4.5V, and the output voltage is 3.3V. The MCU processor 5 adopts a COTREX-MO core CPU. The temperature senso...

Embodiment 2

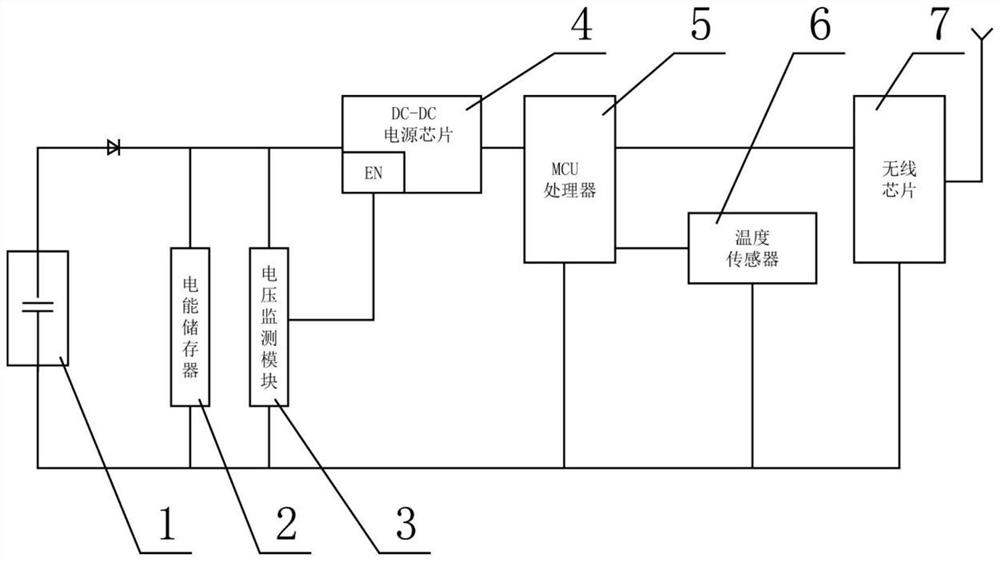

[0031] The embodiment of the present invention discloses an inductive energy storage temperature sensor, such as figure 2 As shown, it includes an energy sensing module 1, an electric energy storage 2, a voltage monitoring module 3, a DC-DC power supply chip 4, an MCU processor 5, a temperature sensor 6 and a wireless chip 7, and the energy sensing module 1 communicates with the The electric energy storage 2 is connected, and the electric energy storage 2 adopts a capacitor, and the electric energy storage 2 is connected with the voltage monitoring module 3, and the voltage monitoring module 3 is connected with the DC-DC power supply chip 4, and the DC - The DC power supply chip 4 supplies power to the MCU processor 5 , the temperature sensor 6 and the wireless chip 7 , and the MCU processor 5 is connected to the temperature sensor 6 and the wireless chip 7 .

[0032] The energy sensing module 1 in this embodiment is a voltage sensing module. The sensor is placed in the equi...

Embodiment 3

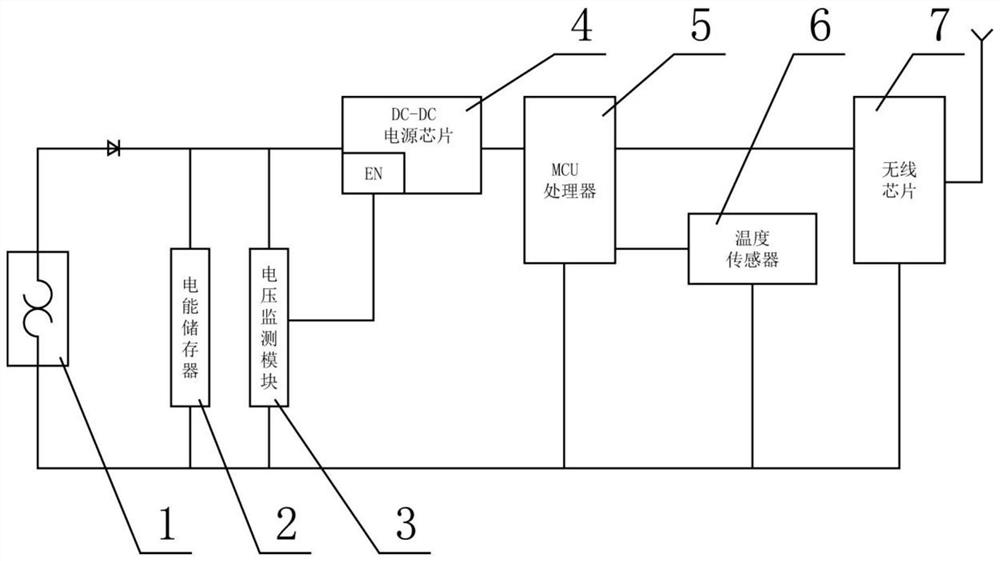

[0034] The embodiment of the present invention discloses an inductive energy storage temperature sensor, such as image 3 As shown, it includes an energy sensing module 1, an electric energy storage 2, a voltage monitoring module 3, a DC-DC power supply chip 4, an MCU processor 5, a temperature sensor 6 and a wireless chip 7, and the energy sensing module 1 communicates with the The electric energy storage 2 is connected, and the electric energy storage 2 adopts a capacitor, and the electric energy storage 2 is connected with the voltage monitoring module 3, and the voltage monitoring module 3 is connected with the DC-DC power supply chip 4, and the DC - The DC power supply chip 4 supplies power to the MCU processor 5 , the temperature sensor 6 and the wireless chip 7 , and the MCU processor 5 is connected to the temperature sensor 6 and the wireless chip 7 .

[0035] The energy sensing module 1 in this embodiment is a temperature difference sensing module. The sensor is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com