Integrated process for detecting and treating toxic gas in crude oil produced by oil field

A toxic gas and crude oil technology, applied in the field of oil and gas exploration and safe production, can solve problems such as human injury, pipeline corrosion, poisonous and harmful, and achieve the effect of ensuring life and health, ensuring safe production, and efficient and harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

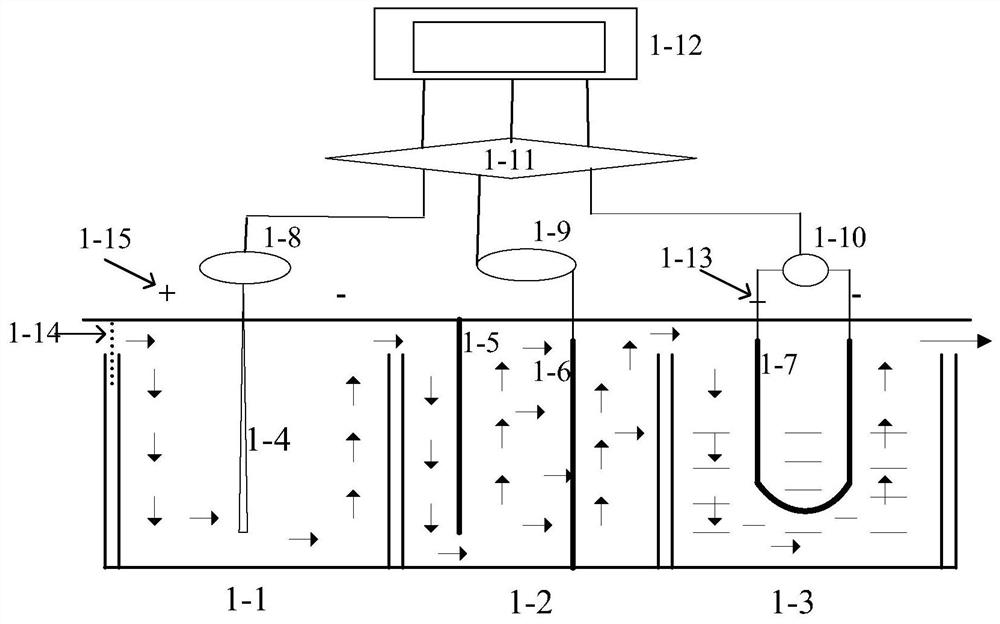

[0092] This embodiment provides a device for detecting toxic gases in crude oil produced in an oil field, and its structural diagram is as follows figure 1 shown, from figure 1 As can be seen, the device includes:

[0093] The display screen 1-12, the electric signal amplifier 1-11, the first electric signal processor 1-8, the second electric signal processor 1-9, the third electric signal processor 1-10 and the radon detection room which are connected in sequence 1-1, hydrogen sulfide detection room 1-2 and mercury detection room 1-3;

[0094] The radon detection chamber 1-1 is provided with an alpha detector 1-4, and the alpha detector 1-4 is electrically connected to the input end of the first electrical signal processor 1-8, and the first electrical signal processor The output end of the device 1-8 is electrically connected to the display screen 1-12 via an electric signal amplifier 1-11; the gas inlet of the radon detection chamber 1-1 is provided with a detachable filt...

Embodiment 2

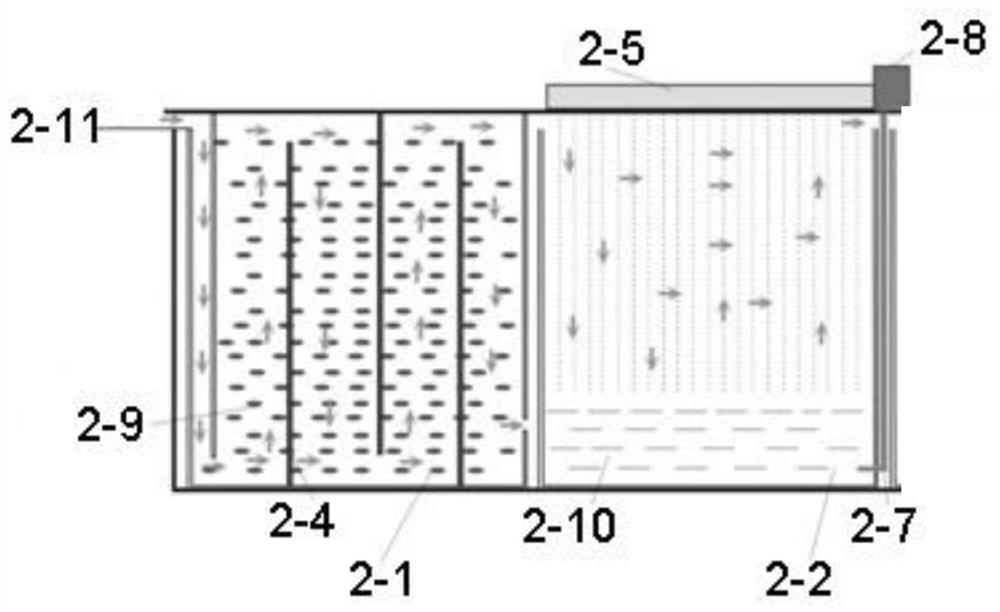

[0107] This embodiment provides a device for harmless treatment of toxic gas in crude oil produced in an oilfield, the schematic diagram of which is shown in figure 2 shown, from figure 2 As can be seen from the figure, the device includes: a radon treatment chamber 2-1 and a hydrogen sulfide rinsing and removal chamber 2-2 connected in sequence;

[0108] The radon treatment chamber 2-1 is provided with several mesh partitions 2-4, and the surface of the mesh partitions 2-4 is provided with biologically active adsorbents 2-9;

[0109] The top of the hydrogen sulfide rinse and removal chamber 2-2 is provided with a shower device 2-5, and the shower device 2-5 is used for spraying sulfuration in the hydrogen sulfide rinse and removal chamber 2-1 from top to bottom. Hydrogen scavengers 2-10.

[0110] In the device provided in this embodiment, the partition is a corrosion-resistant quartz thin plate.

[0111] In the device provided in this embodiment, the biologically active ...

Embodiment 3

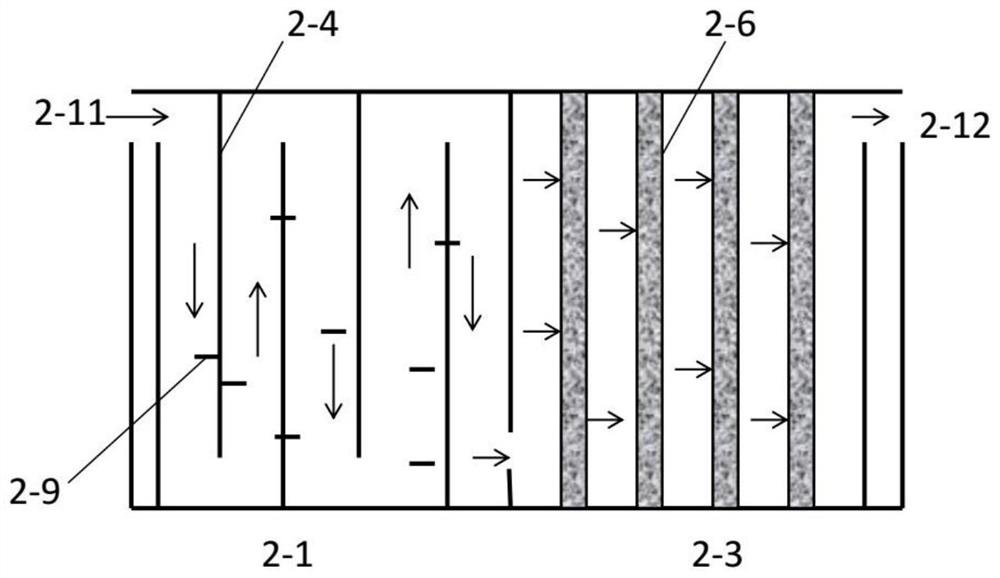

[0115] This embodiment provides a device for harmless treatment of toxic gas in crude oil produced in an oilfield, the schematic diagram of which is shown in image 3 shown, from image 3 As can be seen from the figure, the device includes a radon treatment chamber 2-1 and a mercury treatment chamber 2-3 which are connected in sequence;

[0116] The radon treatment chamber 2-1 is provided with several mesh partitions 2-4, and the surface of the mesh partitions 2-4 is provided with biologically active adsorbents 2-9;

[0117] The mercury treatment chamber 2-3 is provided with several harmful gas treatment nets 2-6, and the harmful gas treatment nets 2-6 are filled with melamine-modified bentonite.

[0118] In the device provided in this embodiment, the partition is a corrosion-resistant quartz thin plate.

[0119] In the device provided in this embodiment, the biologically active adsorbent is biologically activated carbon.

[0120] In the device provided in this embodiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com