High-conductivity gel polymer electrolyte applied to aluminum-air battery as well as preparation method and application of high-conductivity gel polymer electrolyte

A gel polymer, high conductivity technology, used in fuel cell half-cells and primary battery half-cells, fuel cell half-cells and secondary battery half-cells, solid electrolyte fuel cells, etc. , can solve problems such as difficulty in absorbing alkaline electrolyte, increasing electrolyte porosity, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

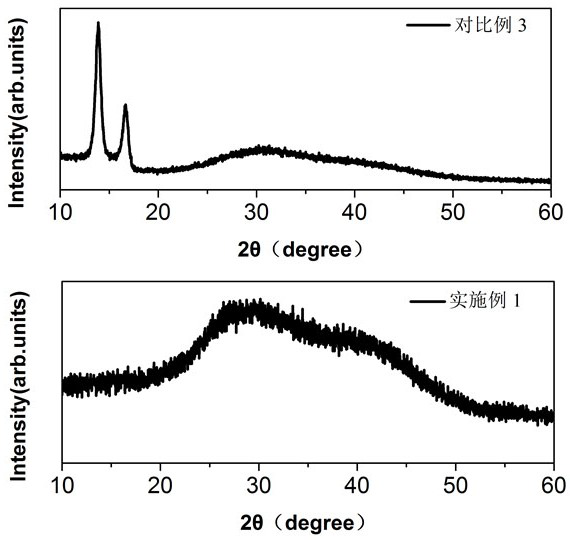

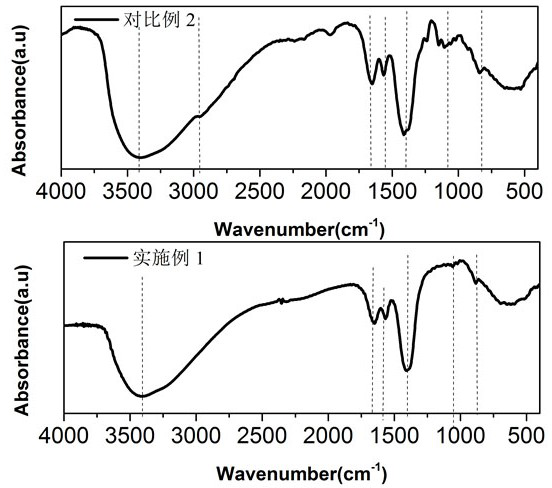

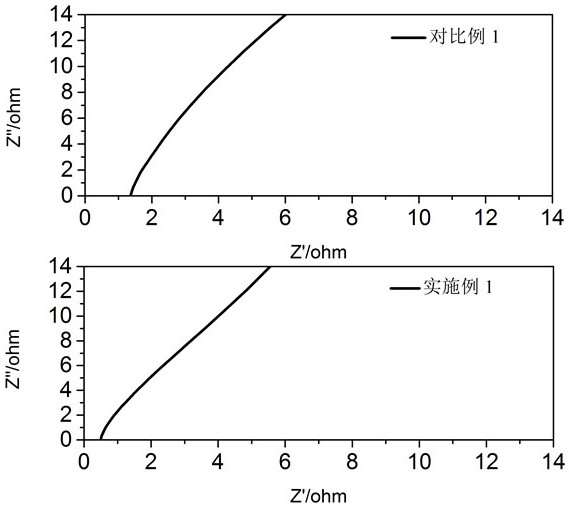

Embodiment 1

[0032] A preparation method of high-conductivity alkaline gel polymer electrolyte, specifically comprising the steps of:

[0033] 1) Weigh 2 g of polyvinyl alcohol (molecular weight: 205,000) and add it to 14 mL of deionized water at room temperature (25°C), and then stir it magnetically in the water bath for about 1 h. The temperature is gradually raised to 85°C until the PVA solution is completely dissolved (observe at all times during the stirring process to prevent the formation of a film on the surface of the solution), and the final solution is milky white foam. Similarly, 2 g of polyethylene oxide (molecular weight: 300,000) was added to 14 mL of deionized water, and magnetically stirred at room temperature for about 1 h to fully dissolve and form a paste to obtain a PEO solution. Then slowly add the fully dissolved PEO solution into the magnetically stirred PVA solution at 85°C, and continue to stir for about 1 hour to make it completely miscible and present a viscous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com