Cavitation device for preparing palm oil-based submicron emulsion

An oil-based, cavitation technology, applied in mixers with rotary stirring devices, chemical/physical/physical-chemical processes using energy, transportation and packaging, etc., can solve the problems of low cavitation efficiency, product pollution, processing capacity Small problems such as high cavitation efficiency, convenient operation, and the effect of promoting the formation of arterial plaques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

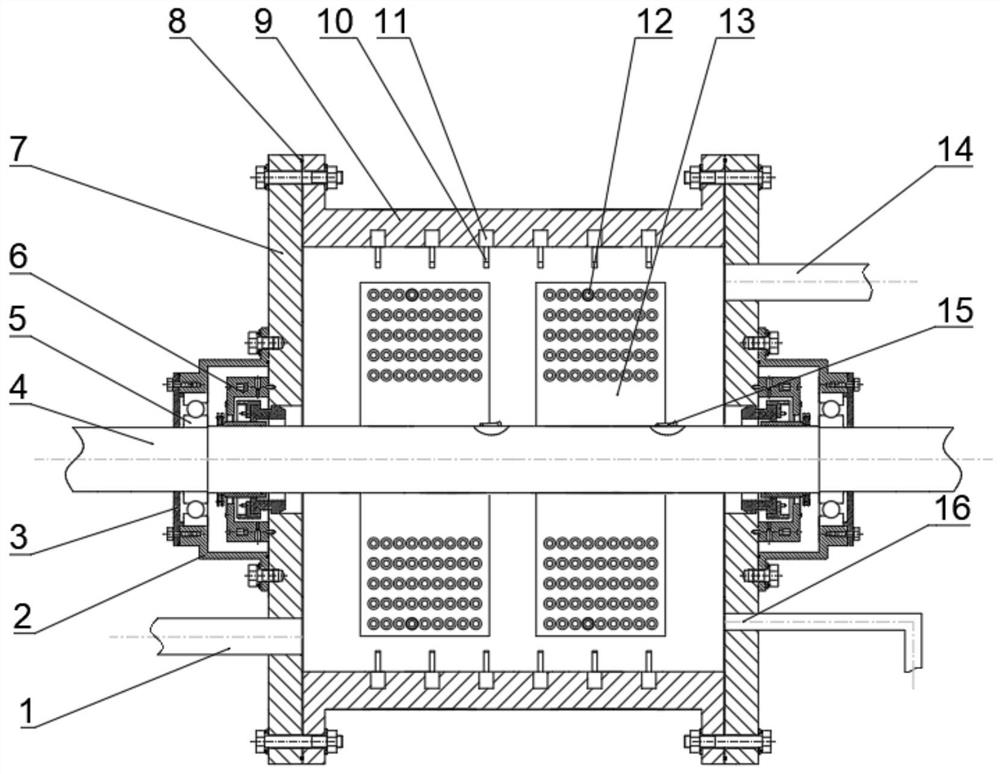

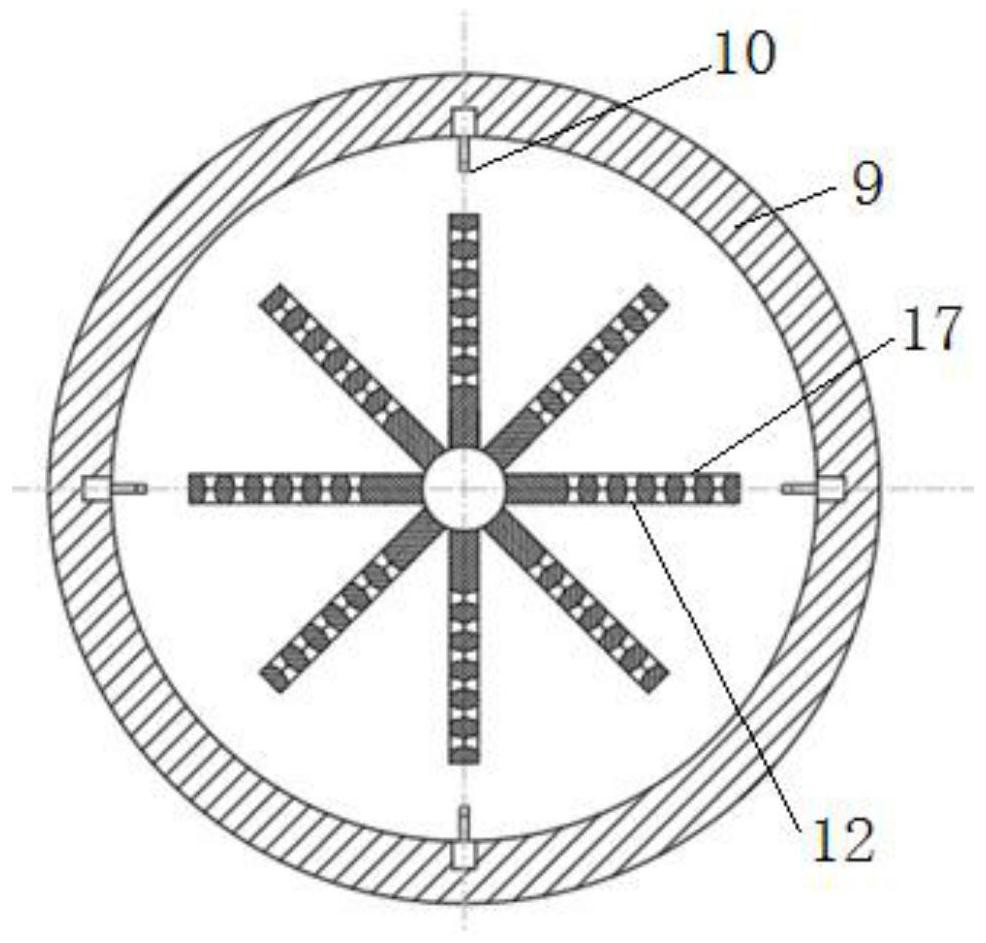

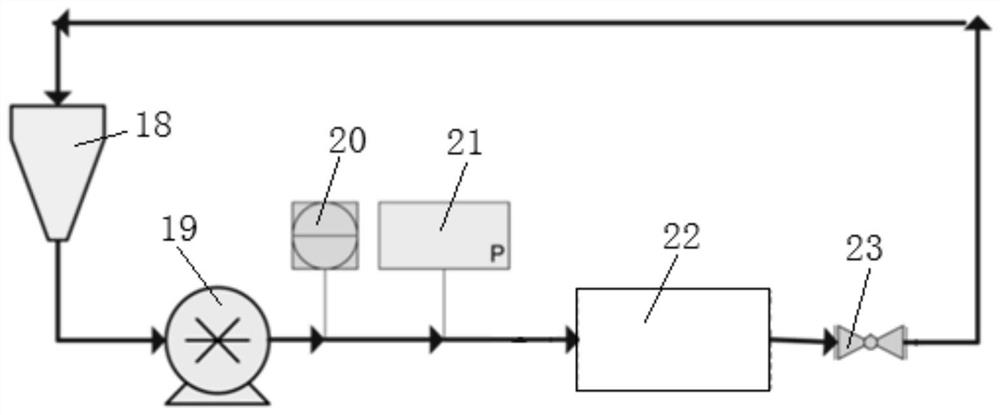

[0032] The present invention prepares the cavitation device of palm oil-based submicron emulsion, such as figure 2 As shown, it includes a stator 9 , a rotor 13 , an ultrasonic probe 10 , an ultrasonic transducer 11 and a rotating shaft 4 . The stator 8 is a closed cylinder with stator end covers 7 arranged on both sides. The inner diameter of the stator is 500mm, the length is 500mm, and the wall thickness is 40mm. The stator end cover 7 is provided with an angular contact ball bearing 5 inside, and a sealing cover 2 is provided outside. The sealing cover 2 is connected with the sealing end cover 3, and a sealing washer 8 is provided at the connection, so that a sealed cavitation cavity is formed inside the stator. The inner wall of the stator is an irregular wall surface with a surface roughness of 0.05 mm, which is conducive to strengthening the cavitation effect. The inner wall of the stator 8 is equipped with an ultrasonic transducer 11 and an ultrasonic probe 10. The ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com