Preparation method of high-purity nano neodymium phosphate powder

A technology of neodymium phosphate and powder, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of serious pollution and low product purity, and achieve the effect of simple production process and friendly production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of high-purity nano neodymium phosphate powder, comprising the following steps:

[0026] (1) Get 230g of neodymium carbonate with a relative rare earth purity of 99.995% (the total amount of rare earth is 50%), add it to 0.5L deionized water, and stir to obtain a neodymium-containing suspension;

[0027] (2) Prepare 1 L of a solution with a concentration of phosphoric acid of 0.73 mol / L and a concentration of nitric acid of 0.05 mol / L, and add 0.2 g of PEG6000;

[0028] (3) At a constant temperature of 25°C, add a neodymium-containing suspension to the phosphoric acid solution, heat up to 80°C under stirring, and keep the temperature constant for 30 minutes to obtain a neodymium phosphate precipitate, filter, wash, and recycle the filtrate to obtain neodymium phosphate at 105 Dry at ℃ for 2 hours to obtain the neodymium phosphate product.

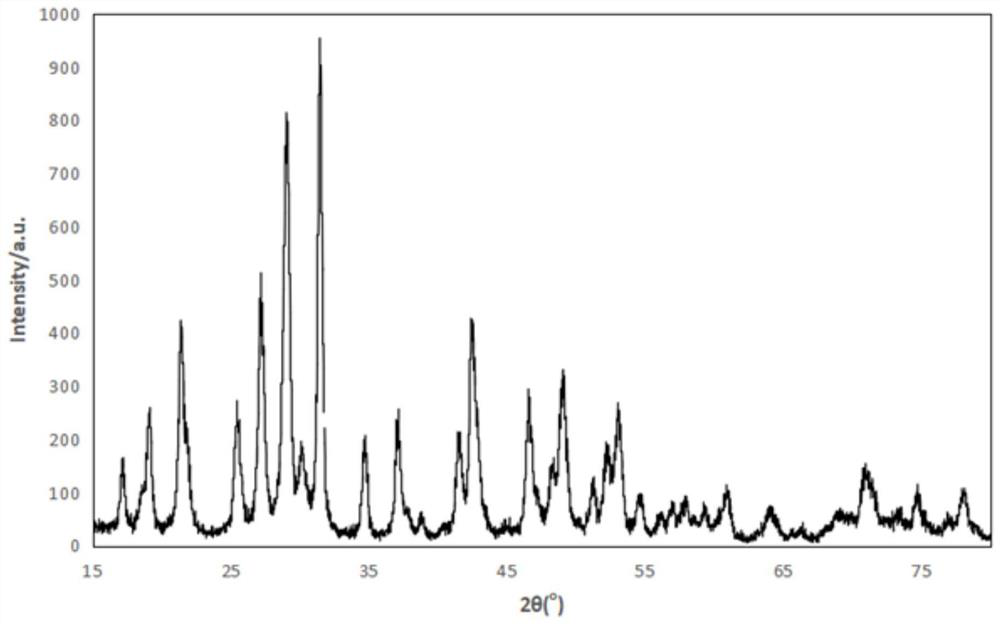

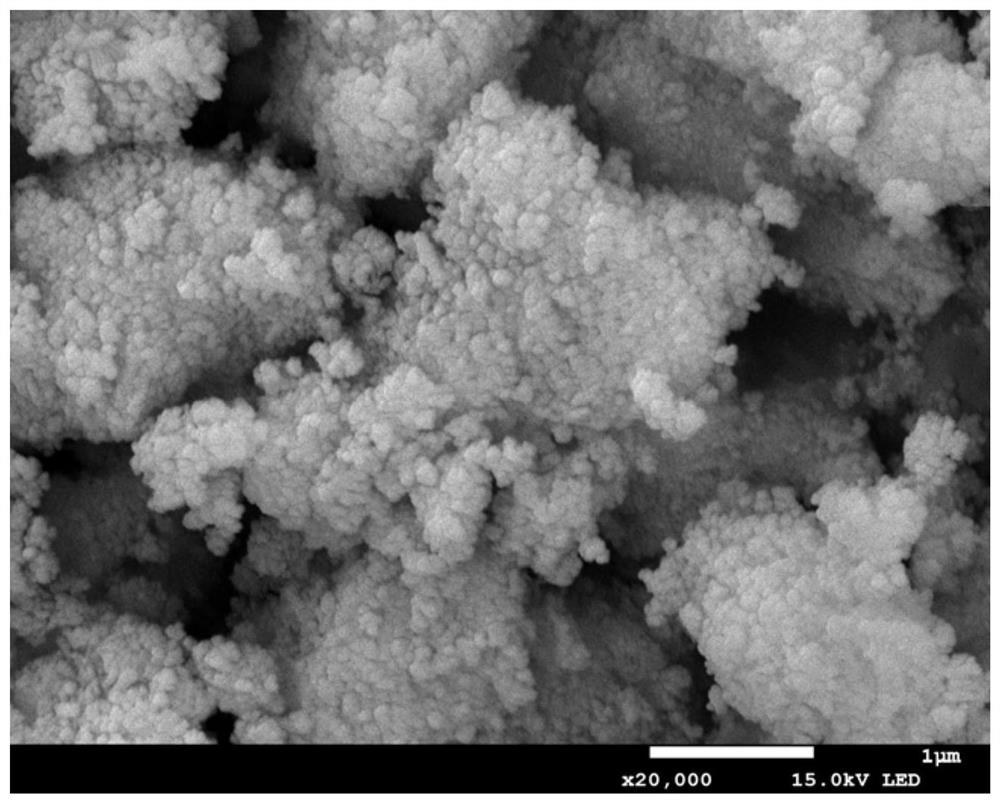

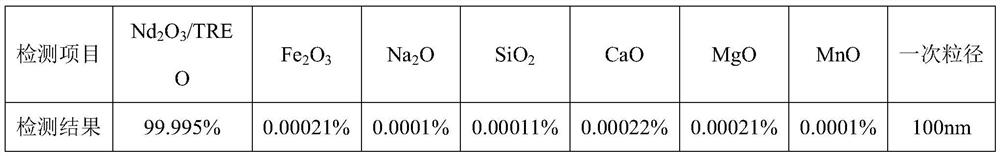

[0029] The composition and the particle size of the neodymium phosphate product obtained in this embodiment a...

Embodiment 2

[0033] A preparation method of high-purity nano neodymium phosphate powder, comprising the following steps:

[0034] (1) Get 1170g of neodymium oxide with a rare earth relative purity of 99.999%, add it to 10L deionized water, and stir to obtain a neodymium-containing suspension;

[0035] (2) preparation phosphoric acid concentration 1.42mol / L, hydrochloric acid concentration 0.01mol / L, CTAB quality are 5L of solution;

[0036] (3) At a constant temperature of 80°C, add the neodymium-containing suspension to the phosphoric acid solution under stirring conditions, age for 2 hours after the addition, filter and wash, and recycle the filtrate, and dry the obtained neodymium phosphate at 150°C for 1 hour to obtain Neodymium phosphate products.

[0037] The composition and particle size of the neodymium phosphate product obtained in this embodiment are shown in Table 2.

[0038] Table 2

[0039]

Embodiment 3

[0041] A preparation method of high-purity nano neodymium phosphate powder, comprising the following steps:

[0042] (1) Get 5000g of basic neodymium carbonate with a relative purity of rare earth of 99.998% (the total amount of rare earth is 59%), add it to 10L of deionized water, and stir to obtain a neodymium-containing suspension;

[0043] (2) preparation phosphoric acid concentration 1.5mol / L, nitric acid concentration 0.1mol / L, CTAB quality are 12L of the solution of 15g;

[0044] (3) At a constant temperature of 90°C, add the neodymium-containing suspension to the phosphoric acid solution under stirring conditions, age for 1 hour after the addition, filter and wash, and recycle the filtrate, and dry the obtained neodymium phosphate at 100°C for 3 hours to obtain Neodymium phosphate products.

[0045] The composition and particle size of the neodymium phosphate products obtained in the examples are shown in Table 3.

[0046] table 3

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com