Modified polypropylene composite material with high adhesive property as well as preparation method and application thereof

A technology of composite material and polypropylene, which is applied in the field of modified polypropylene composite material with high bonding performance and its preparation, can solve the problems of low tensile strength and rigid elongation at break, and achieve excellent appearance and high bonding strength. and the effect of improved bonding performance, good mechanical properties and surface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-2

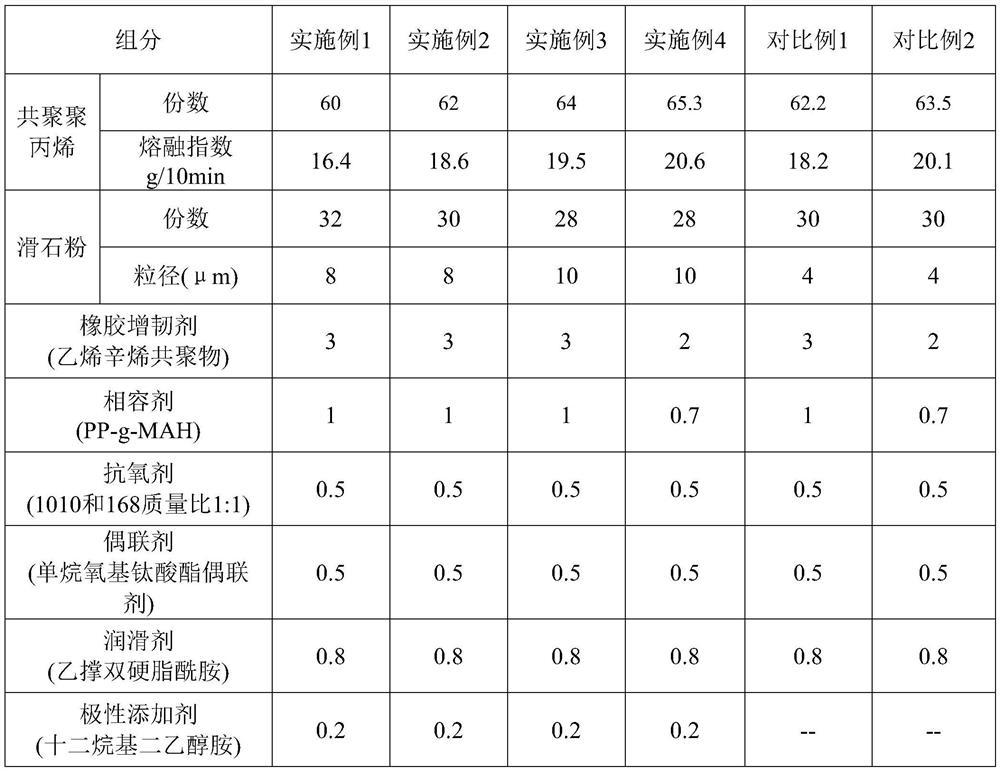

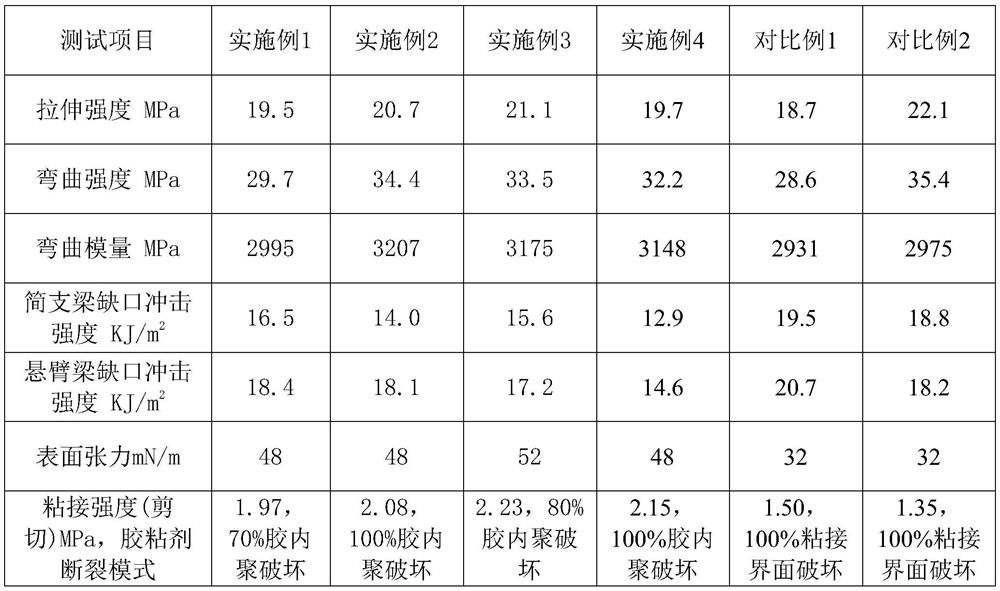

[0028] A modified polypropylene material with high adhesive performance is provided. The raw material ratios of Examples 1-4 and Comparative Examples 1-2 are shown in Table 1. Unless otherwise specified, parts refer to parts by weight.

[0029] The preparation method of the modified polypropylene material of above-mentioned high bonding performance, comprises the following steps:

[0030] (1) take raw materials by weight ratio;

[0031] (2) Add polypropylene, talcum powder, rubber toughening agent, compatibilizer, antioxidant, coupling agent, lubricant and polar additives into a high-speed mixer and mix evenly at a speed of 500-3000r / min. The time is 5-20 minutes to obtain the mixed material;

[0032] (3) Add the mixed material in step (2) into the twin-screw extruder, and cool and granulate after melting and extrusion; the processing temperature of the twin-screw extruder is set at 100 to 6 zones respectively 120°C, 120~140°C, 140~160°C, 160~180°C, 180~200°C, 180~200°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com