A tungstate-based photothermal conversion temperature measurement material and its preparation method and application

A photothermal conversion, tungstate technology, applied in luminescent materials, chemical instruments and methods, thermometers, etc., can solve the problems of difficult large-scale production and application, complicated preparation process, slow heating rate, etc., to achieve non-toxic raw materials, preparation Process cleaning and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

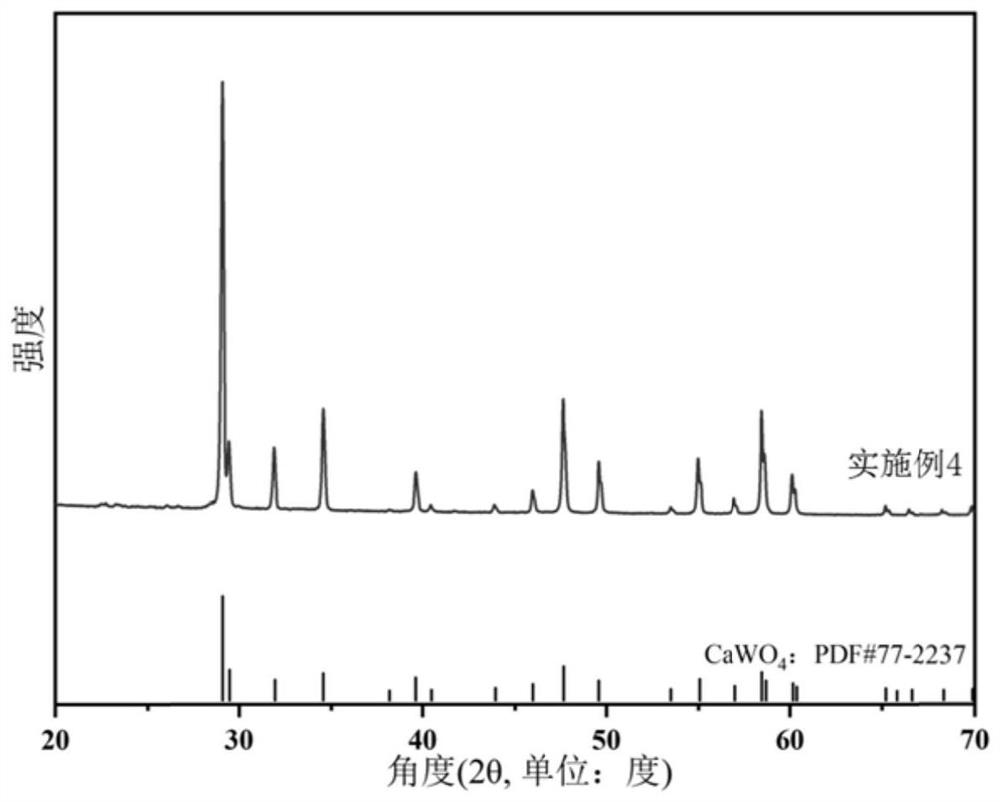

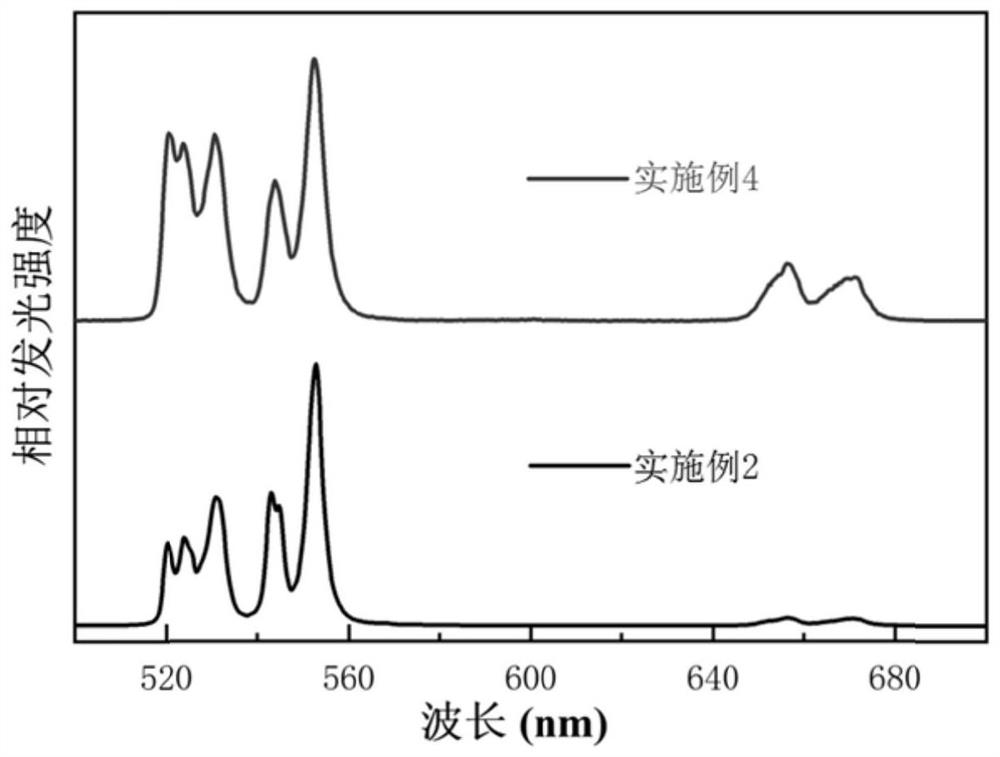

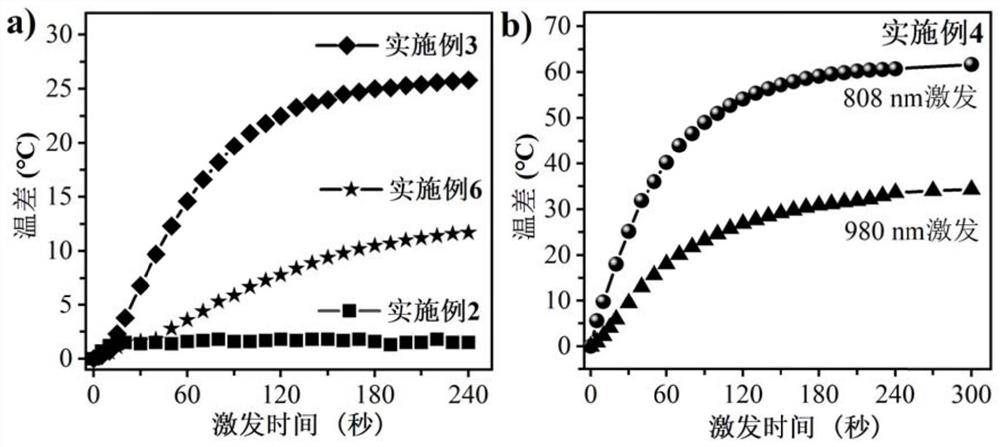

[0037] Embodiments 1 to 6 in the present invention adopt the same preparation process steps, and the specific chemical equations are shown in Table 1.

[0038] Table 1

[0039]

[0040]

[0041]The preparation process steps of the above-mentioned embodiment include the following steps:

[0042] (1) Selection of raw materials: Li is selected during preparation 2 CO 3 (purity 99.99%), CaCO 3 (purity 99.99%), WO 3 (99% purity), Er 2 O 3 (purity 99.9%), La 2 O 3 (purity 99.99%), Yb 2 O 3 (99.99% purity), and Nd 2 O 3 (purity 99.9%) as the raw material, weigh the raw material strictly according to its chemical formula, then place all the raw materials in the agate mortar, add an appropriate amount of anhydrous ethanol, stir, mix and grind for 1 to 2 hours until fully mixed;

[0043] (2) The uniformly ground powder was placed in a corundum crucible, gradually heated to 1000°C at a heating rate of 3°C / min in air, sintered at high temperature for 4 hours, and cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com