IrRu-based multi-component alloy oxygen evolution catalyst and preparation method thereof

A technology of oxygen precipitation and catalyst, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

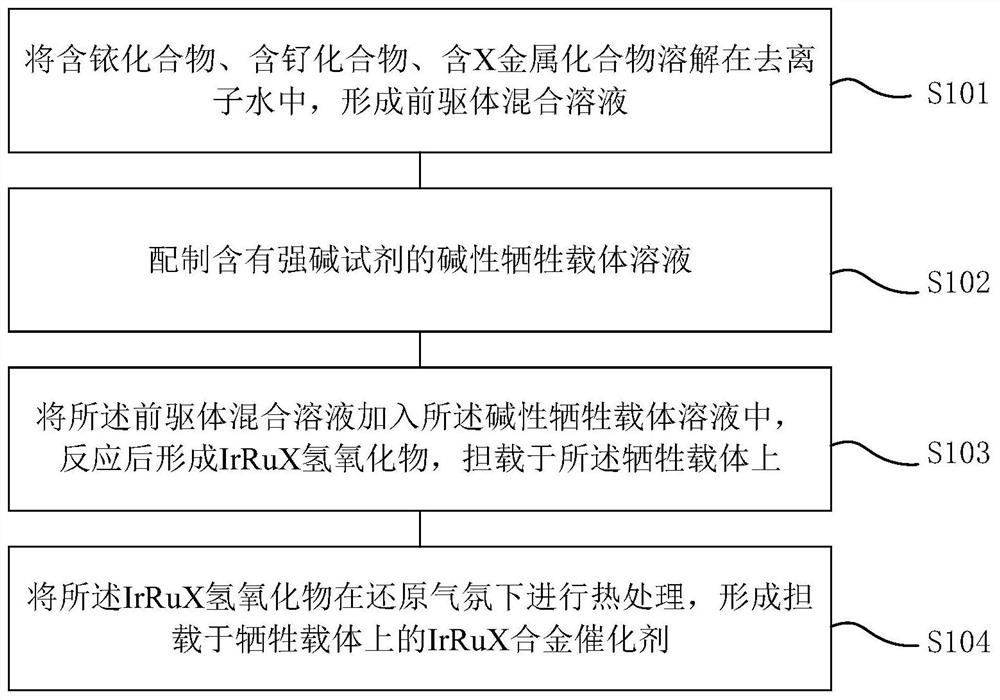

Method used

Image

Examples

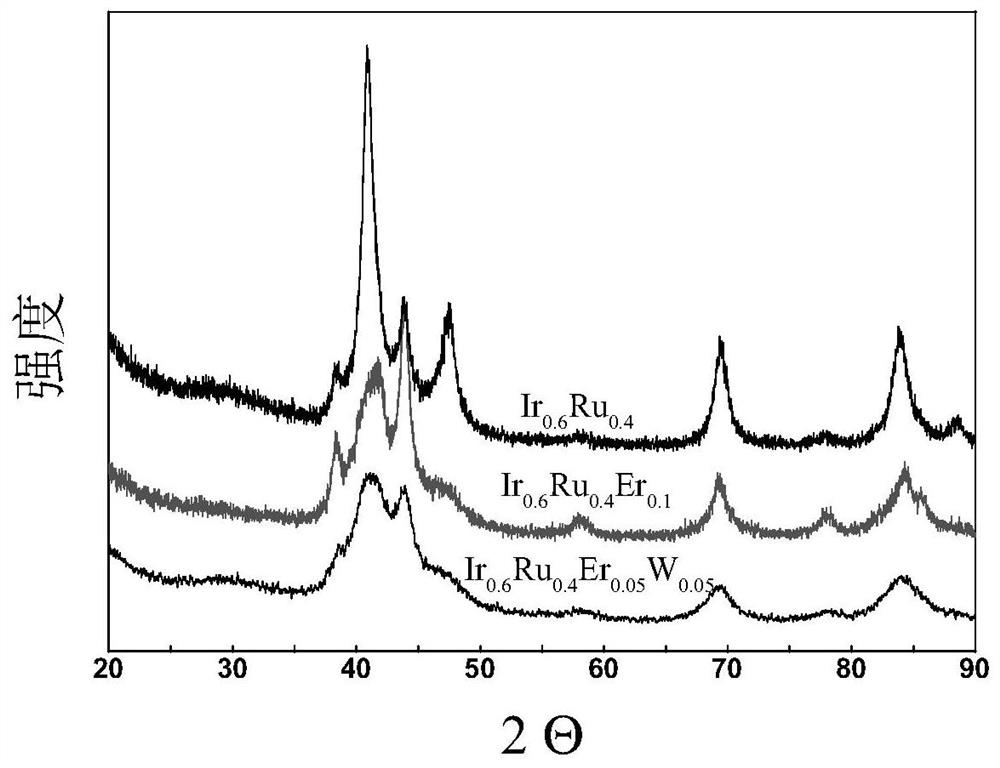

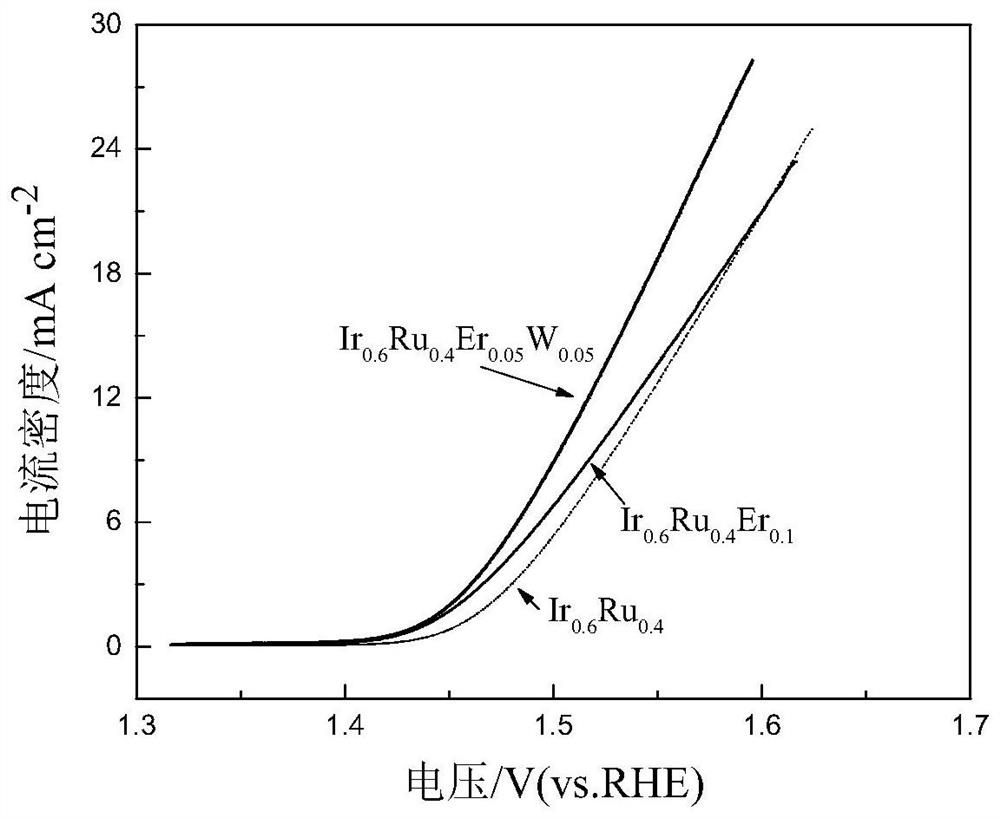

Embodiment 1

[0055] 1) Preparation of metal precursor mixed solution: according to the molar ratio of Ir:Ru=6:4, take chloroiridic acid and ruthenium chloride, and then take erbium chloride hexahydrate with 10% total molar weight of iridium and ruthenium and dissolve them in deionized water , stirred until completely dissolved; adding EDTA, a surfactant with a total molar weight of 1% iridium and ruthenium, to the solution dissolved with metal ions, stirring and mixing evenly, and configuring a precursor mixed solution.

[0056] 2) Preparation of alkaline sacrificial carrier solution: take the strong alkali reagent KOH with a molar ratio of 5:1 to the total molar amount of iridium and ruthenium, and then take the sacrificial agent carrier nano-magnesium oxide with the same molar amount as KOH, so that the two are dispersed in the deionized In water, stir vigorously to disperse evenly.

[0057] 3) Precipitation reaction: Add the metal precursor mixed solution drop by drop to the alkaline sa...

Embodiment 2

[0061] 1) Preparation of metal precursor mixed solution: take chloroiridic acid and ruthenium chloride according to the molar ratio of Ir:Ru=6:4, and then respectively take erbium chloride hexahydrate and molar amount of 5% of the total molar amount of iridium and ruthenium Tungsten chloride with an amount of 5% of the total molar amount of iridium and ruthenium is dissolved in deionized water and stirred until completely dissolved; the surfactant EDTA with 1% of the total molar amount of iridium and ruthenium is added to the solution dissolved with metal ions, stirred and mixed evenly, Obtain the precursor mixture.

[0062] 2) preparation of sacrificial carrier solution: take the strong base reagent KOH whose molar ratio is 5:1 with the total molar amount of iridium and ruthenium, and then take the sacrificial agent carrier nano-magnesium oxide with the same molar amount as KOH, and disperse the two in deionized water, Stir vigorously to disperse evenly.

[0063] 3) Precipit...

Embodiment 3

[0067] 1) Preparation of metal precursor mixed solution: take chloroiridic acid and ruthenium chloride according to the molar ratio of Ir:Ru=7:3, and then dissolve erbium chloride hexahydrate with 10% of the total molar weight of iridium and ruthenium in deionized water, Stir until completely dissolved; add surfactant EDTA with a total molar weight of iridium and ruthenium of 1% to the solution in which the metal ions are dissolved, stir and mix evenly, and prepare a precursor mixed solution.

[0068] 2) preparation of sacrificial carrier solution: take the strong base reagent KOH whose molar ratio is 5:1 with the total molar amount of iridium and ruthenium, and then take the sacrificial agent carrier nano-magnesium oxide with the same molar amount as KOH, and disperse the two in deionized water, Stir vigorously to disperse evenly;

[0069] 3) Precipitation reaction: Add the metal precursor solution drop by drop to the mixed solution of strong base reagent and sacrificial agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com