Neutralizing soaping agent

A soaping agent and emulsifier technology, applied in the field of neutralizing soaping agents, can solve the problems of less pretreatment and dyeing auxiliaries, floating color removal and anti-re-staining need to be improved, white emulsion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

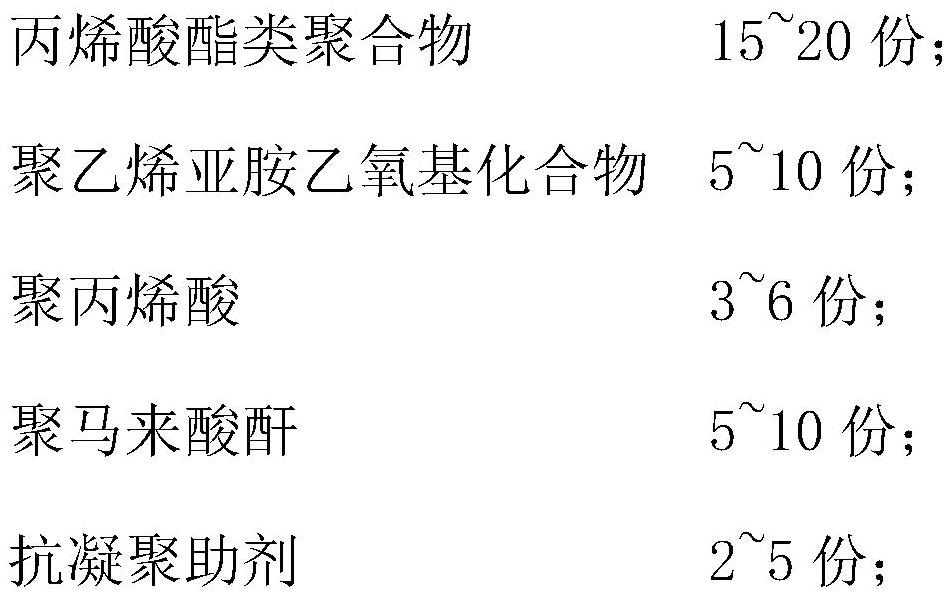

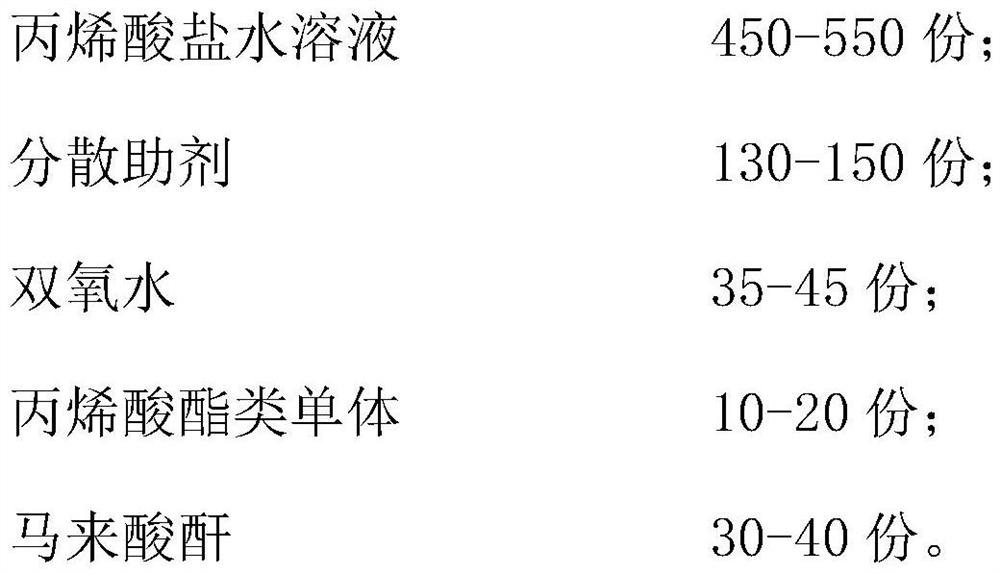

[0051] The acrylate polymer is prepared from components comprising the following parts by mass:

[0052]

[0053] Wherein, the aqueous solution of acrylate salt is sodium acrylate aqueous solution, and the preparation method is to neutralize the acrylic acid to pH=8 with sodium hydroxide (32%) aqueous solution. Phenylpropionic acid is 3-phenylpropionic acid and was purchased from Nantong Tianxiang Biological Engineering Co., Ltd.

[0054] The dispersing aid is JFC-2 dispersing agent of Jiangsu Haian Petrochemical Co., Ltd.

[0055] The acrylate monomer was n-butyl acrylate and was purchased from Nantong Runfeng Petrochemical Co., Ltd.

[0056] Maleic anhydride was purchased from Nantong Runfeng Petrochemical Co., Ltd.

[0057] The preparation technology of acrylic polymer specifically comprises the following steps:

[0058] According to parts by mass, put the acrylate monomer and maleic anhydride into the dispersing aid to stir and disperse, raise the temperature of the ...

preparation example 2

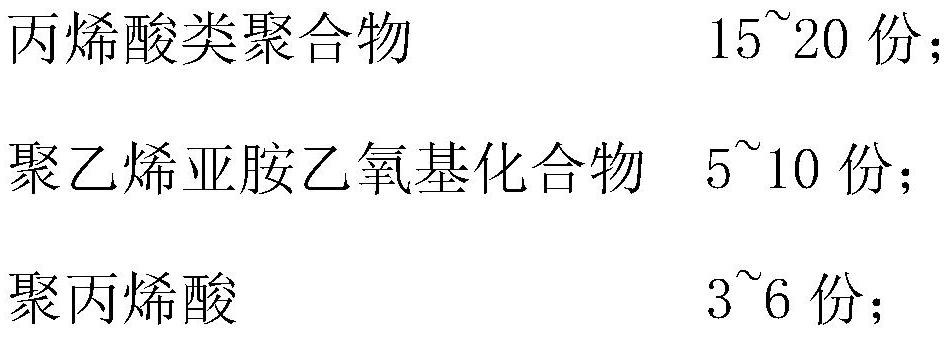

[0060] The difference between Preparation Example 2 and Preparation Example 1 is that the dispersing aid is not a conventional commercially available JFC-2 dispersant, and the dispersing aid includes the following components in parts by mass:

[0061] Emulsifier 2kg;

[0062] Slightly soluble magnesium salt or insoluble magnesium salt 5kg;

[0063] 133kg of water.

[0064] Among them, the emulsifier is sodium cumene sulfonate and is purchased from Guangzhou Chuangen Chemical Technology Co., Ltd.; and the slightly soluble or insoluble magnesium salt is magnesium hydroxide.

[0065] The preparation technology of acrylic polymer specifically comprises the following steps:

[0066] S1: According to the mass ratio, the emulsifier and slightly soluble magnesium salt or insoluble magnesium salt are added with water and stirred to disperse to obtain a dispersion;

[0067] S2: According to parts by mass, put the acrylate monomer and maleic anhydride into the dispersion obtained in s...

preparation example 3

[0069] The difference between Preparation Example 3 and Preparation Example 2 is that in the dispersing aid, the emulsifier is a mixture of sodium cumene sulfonate and isomeric decanol polyoxyethylene ether in an equal mass ratio. Isomerized decanol polyoxyethylene ether was purchased from Jiangsu Haian Petrochemical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com