Method and device for preparing low-VOC and low-odor polypropylene composite material by adopting multi-stage directional extraction and adsorption method

A technology of composite materials and polypropylene, applied in the field of polymer materials, can solve the problems of easy damage, limited adsorption and removal effect of adsorbent, difficult extraction agent, etc., to avoid mutual influence or interference, avoid single extraction effect, and avoid mutual The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

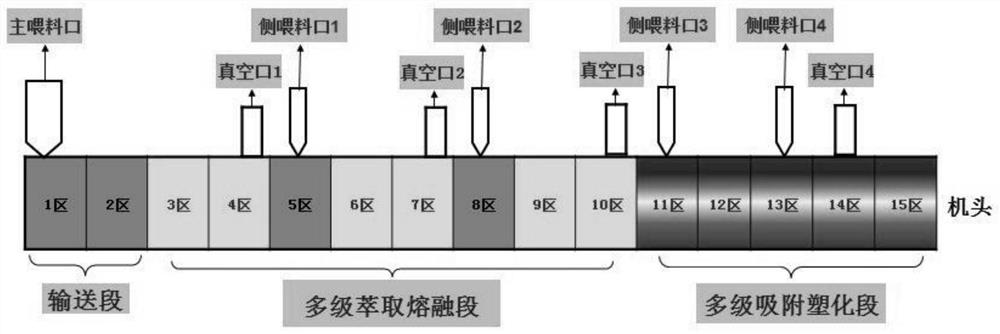

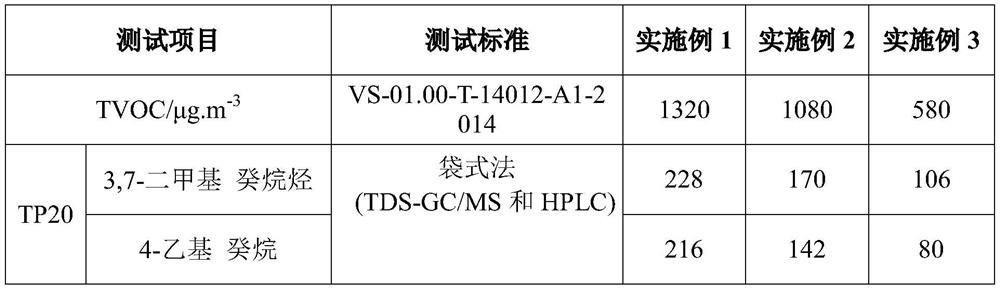

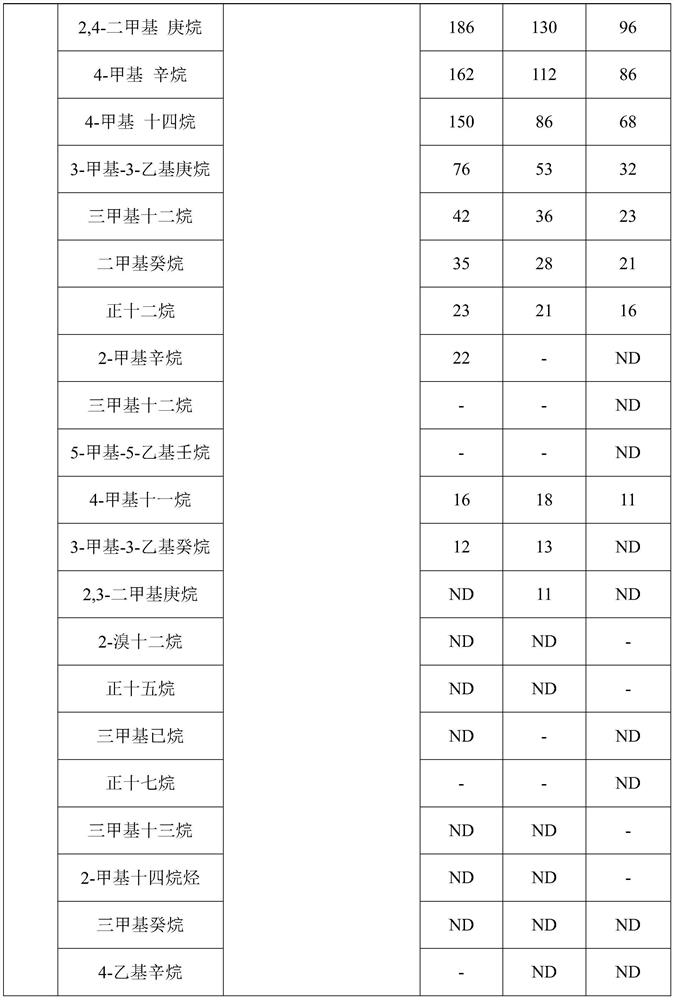

[0027] Preparation of low-VOC and low-odor polypropylene composites by multi-stage directional extraction and adsorption

[0028] Weigh 68 parts of polypropylene resin, 1 part of naphthenic acid, 10 parts of calcium carbonate, 15 parts of conductive agent, 0.2 part of antioxidant 1010, 1 part of polyol wax and 0.05 part of silicone oil, mix well and add from the main feeding port Barrel, the screw speed is controlled to be 300rpm, through the screw, the mixture first passes through the conveying section (1-2 zone) of the barrel, the temperature of this section 1-2 zone is 70°C and 100°C in sequence, and then enters the extraction and melting section (3- Zone 4), the temperature in Zone 3-4 of this section is 160°C and 180°C in turn, after full extraction, vacuum extraction is carried out through the vacuum port 1 set on Zone 4 with a vacuum degree of -0.08MPa to remove naphthenic acid and dissolved Harmful volatile organic compounds in naphthenic acid; then enter the extractio...

Embodiment 2

[0030] Preparation of low-VOC and low-odor polypropylene composites by multi-stage directional extraction and adsorption

[0031] Weigh 82 parts of polypropylene resin, 1.5 parts of dicarboxylic acid, 5 parts of talcum powder, 5 parts of wear-resistant agent, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.5 part of oxidized polypropylene wax and 0.06 part of silicone oil After mixing, add the barrel from the main feeding port, control the screw speed to 350rpm, and make the mixture pass through the conveying section (1-2 area) of the machine barrel through the screw, and the temperature of the 1-2 area of this section is 60 ° C and 90 ° C ℃, and then enter the extraction and melting section (3-4 zone), the temperature of this section 3-4 zone is 160 ℃, 180 ℃ in turn, after full extraction, carry out vacuum extraction through the vacuum port 1 set on the 4 zone, the vacuum degree is -0.08MPa, remove dicarboxylic acid and harmful volatile organic compounds dissol...

Embodiment 3

[0033] Preparation of low-VOC and low-odor polypropylene composites by multi-stage directional extraction and adsorption

[0034] Weigh 96 parts of polypropylene resin, 0.5 part of diphosphoric acid, 0.5 part of weathering agent, 0.5 part of antioxidant 1010, 0.5 part of antioxidant 168, 0.1 part of wax ester and 0.05 part of silicone oil, mix well and add from the main feeding port Barrel, the screw speed is controlled to be 400rpm, through the screw, the mixture first passes through the conveying section (1-2 zone) of the barrel, the temperature of this section 1-2 zone is 80°C and 90°C in turn, and then enters the extraction and melting section (3- Zone 4), the temperature in Zone 3-4 of this section is 160°C and 180°C in turn, after full extraction, vacuum extraction is carried out through the vacuum port 1 set on Zone 4, with a vacuum degree of -0.08MPa, to remove diphosphoric acid and soluble Harmful volatile organic compounds in diphosphoric acid; then enter the extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com