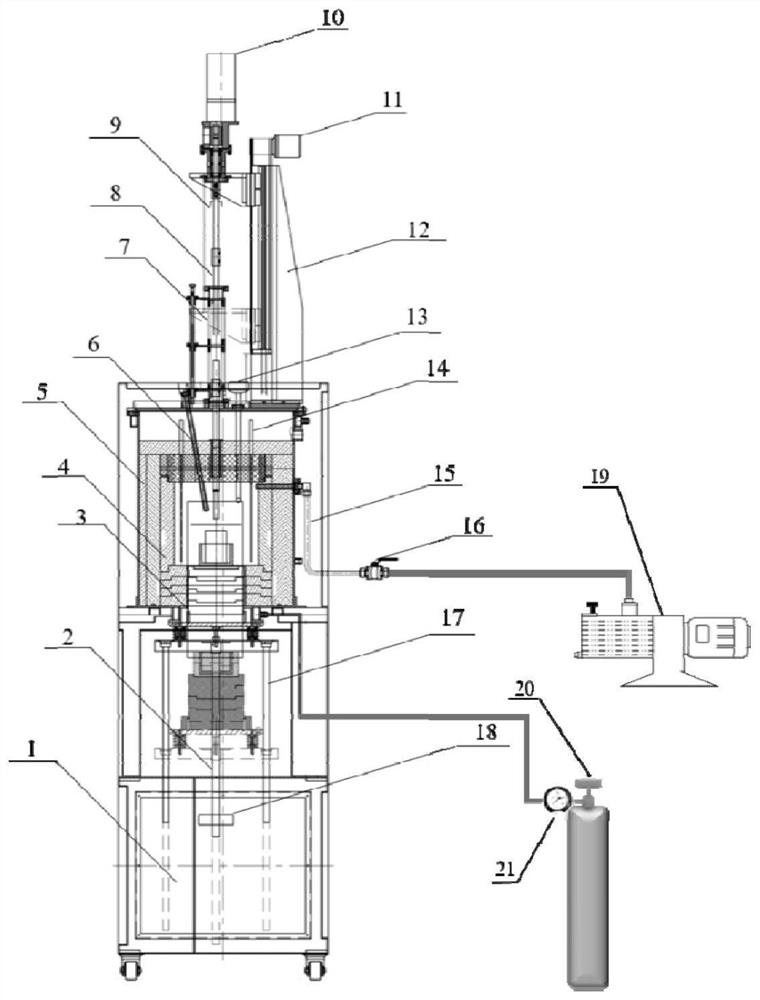

Testing device for evaluating static and dynamic erosion resistance of refractory material, and testing method thereof

A technology of refractory materials and test equipment, applied in the field of refractory materials, can solve the problems of high hardness, difficult processing, and complicated connection methods of refractory materials, and achieve the effects of reducing labor intensity, realizing automation, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

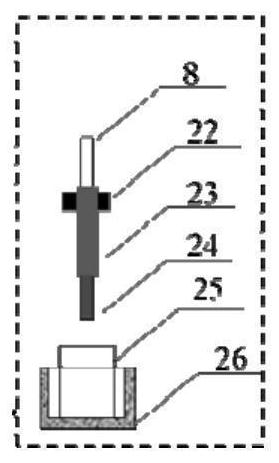

[0063] (1) Cut a cylindrical sample with a diameter of 15 mm and a height of 90 mm from a complete refractory brick and put it in a blast drying oven to dry for 12 hours. After the drying is completed, take out the sample, measure the size of the slag end of the sample with a precision vernier caliper with an accuracy of 0.02mm, and take pictures to record; because the refractory material is hard and difficult to process, graphite rods with good processing characteristics are selected as corundum rods and The intermediate connection device between the two refractory samples is to drill a hole diameter of φ16mm and depth of 17.5mm in the axial direction on the upper end of the graphite rod, and then drill a hole diameter of 5mm in the radial direction at the upper end of the graphite rod 5mm down, and then cooperate Bolts and nuts made of graphite with a length of about 35mm are used to pass through the corundum rod and graphite rod at the same time to achieve a stable connectio...

Embodiment 2

[0077] (1) Cut a cylindrical sample with a diameter of 15 mm and a height of 90 mm from a complete refractory brick and put it in a blast drying oven to dry for 12 hours. After the drying is completed, take out the sample, measure the size of the slag end of the sample with a precision vernier caliper with an accuracy of 0.02 mm, and take pictures to record; then complete a tight fit with the graphite rod, and drill a pin hole with a diameter of 10 mm on the upper end of the graphite rod to ensure The centerline of the hole is parallel to the specimen ground.

[0078] (2) Cut 1000g of the target steel sample, put it into the corundum crucible, and then put the steel crucible into the protective crucible stably.

[0079] (3) Connect the sample to the corundum connecting rod on the device, insert a graphite bolt into the drill hole and fix it with a nut, and adjust the position of the steel crucible to ensure that the refractory sample is in the center of the crucible.

[0080]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com