Plant double-protein fermented flavored yoghurt and preparation method thereof

A fermented flavor and double protein technology, applied in the fields of milk preparations, dairy products, food science, etc., can solve the problems of restricting the market development value of fermented fermented soymilk, deodorizing soymilk, etc., achieving good taste, less bean smell, good taste The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

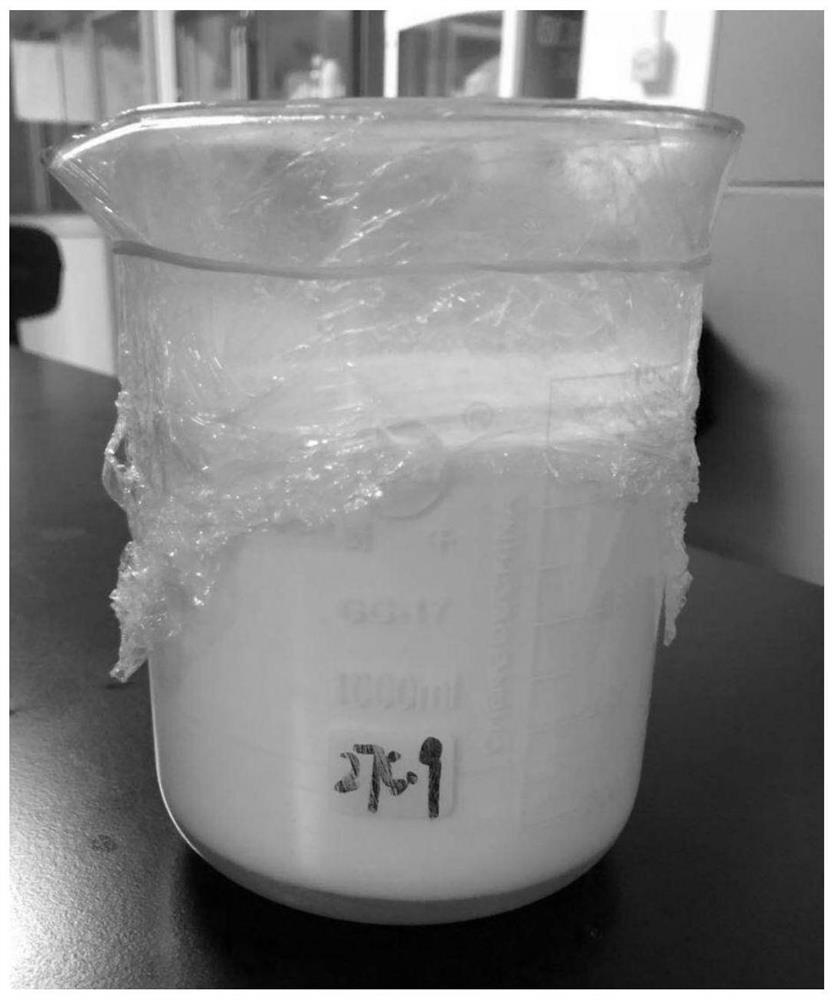

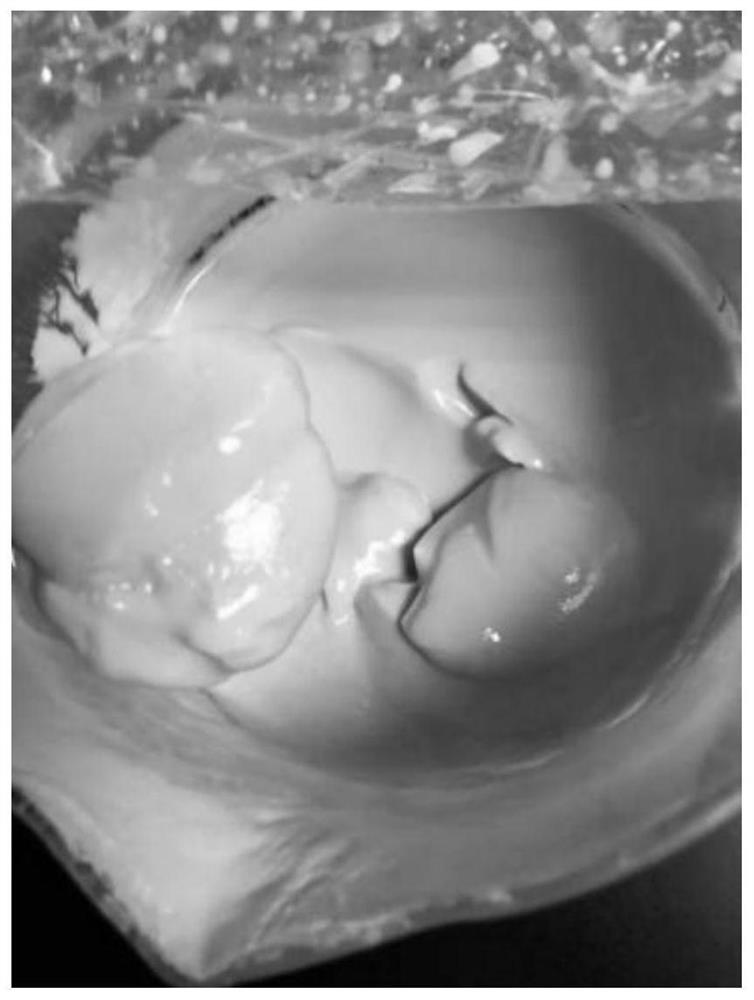

Image

Examples

Embodiment 1

[0036] Raw material formula: 17% of instant soybean powder, 6% of white sugar, 0.4% of yogurt stabilizer, 7% of coconut milk, appropriate amount of bacteria, and the balance is water.

[0037] 1. Technological process: ingredients→chemical materials→constant volume→homogenization→sterilization→inoculation and fermentation→overcooling→finished and put into storage

[0038] 2. Process description:

[0039] (1) Heat the water in the batching tank to 65°C and add instant soybean powder;

[0040] (2) Heat the raw milk in circulation, add white granulated sugar, stabilizer, coconut milk, and circulate heat preservation;

[0041] (3) Pour the feed liquid in the batching tank into the batching buffer tank for quantification, and the semi-finished products after quantification are homogenized and then pasteurized

[0042] (4) Inoculate fermentation strains for fermentation, and the acidity at the end of fermentation is ≥ 70 0 T;

[0043] (5) After the fermentation is over, the prod...

Embodiment 2

[0048] Raw material formula: 17% of instant soybean powder, 6% of white sugar, 0.5% of yogurt stabilizer, 7% of coconut milk, appropriate amount of bacteria, and the balance is water.

[0049] 2. Technological process: ingredients→chemical materials→constant volume→homogenization→sterilization→inoculation and fermentation→overcooling→finished and put into storage

[0050] 2. Process description:

[0051] (1) Heat the water in the batching tank to 65°C and add instant soybean powder;

[0052] (2) Heat the raw milk in circulation, add white granulated sugar, stabilizer, coconut milk, and circulate heat preservation;

[0053] (3) Pour the feed liquid in the batching tank into the batching buffer tank for quantification, and the semi-finished products after quantification are homogenized and then pasteurized

[0054] (4) Inoculate fermentation strains for fermentation, and the acidity at the end of fermentation is ≥ 70 0 T;

[0055] (5) After the fermentation is over, the prod...

Embodiment 3

[0059]Raw material formula: 17% of instant soybean powder, 6% of white sugar, 0.6% of yogurt stabilizer, 7% of coconut milk, appropriate amount of bacteria, and the balance is water.

[0060] 3. Technological process: ingredients→chemical materials→constant volume→homogenization→sterilization→inoculation and fermentation→overcooling→finished and put into storage

[0061] 2. Process description:

[0062] (1) Heat the water in the batching tank to 65°C and add instant soybean powder;

[0063] (2) Heat the raw milk in circulation, add white granulated sugar, stabilizer, coconut milk, and circulate heat preservation;

[0064] (3) Feed liquid in the batching tank is poured into the batching buffer tank for quantification, and the semi-finished product after quantification is subjected to homogeneous treatment, and then pasteurized;

[0065] (4) Inoculate fermentation strains for fermentation, and the acidity at the end of fermentation is ≥ 70 0 T;

[0066] (5) After the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com