Poly-L-lactic acid (PLLA) filler for injection and preparation method thereof

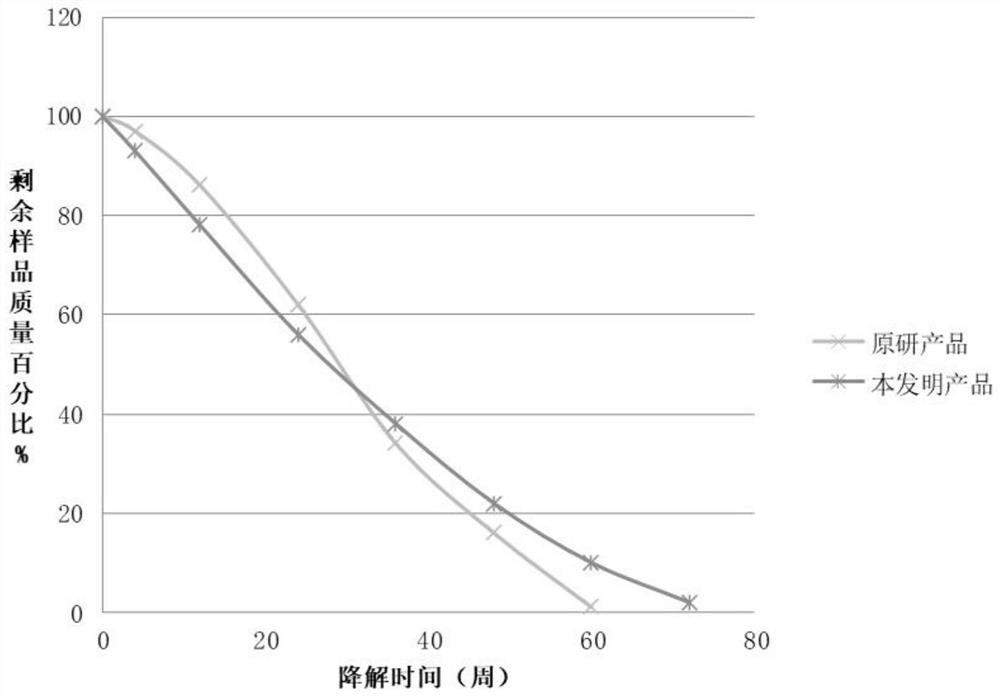

一种聚左旋乳酸、填充剂的技术,应用在医药配方、医药科学、假体等方向,能够解决填充剂复溶时间长、易出现皮下结节、混悬液不均匀等问题,达到降解维持时间长、不易漂浮和沉淀、制备工艺优化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of small-diameter poly-L-lactic acid microparticles

[0037] Weigh 30g of poly-L-lactic acid with a viscosity-average molecular weight of 12,000, put it in a three-necked bottle, add a mixed solvent of 600mL of dichloromethane and 1.2L of ethanol, heat to reflux, cool down slightly after the solid is completely dissolved, and the liquid is slightly cloudy, and then Use a peristaltic pump under heating and reflux conditions, drop 300mL of ethanol at a rate of 2mL / min, control the stirring speed during the dropping process to 300-400rpm, pour 600mL of ethanol to dilute after the dropping is completed, evaporate 1L of solvent at normal pressure, add Dilute with 1L of water, cool down to room temperature, filter, rinse the filter cake with ethanol, and pass through a 200-mesh sieve after drying to obtain 28.8 g of poly-L-lactic acid particles with a particle size of D90=12.2 μm.

Embodiment 2

[0038] Example 2 Preparation of medium-sized poly-L-lactic acid microparticles

[0039] Weigh 30g of poly-L-lactic acid with a viscosity-average molecular weight of 38,000, put it in a three-neck bottle, add a mixed solvent of 600mL of dichloromethane and 900mL of ethanol, heat to reflux, and cool down slightly after the solid is completely dissolved. The solution is slightly cloudy, and then heated Under reflux conditions, use a peristaltic pump to drip 600mL of ethanol at a rate of 3mL / min. During the dropping process, control the stirring speed at 200-300rpm. Stir in purified water, cool down to room temperature, filter, rinse the filter cake with ethanol, and pass through a 200-mesh sieve after drying to obtain 29.7 g of poly-L-lactic acid particles with a particle size of D90 = 58.4 μm.

Embodiment 3

[0040] Example 3 Preparation of large-diameter poly-L-lactic acid microparticles

[0041] Weigh 30g of poly-L-lactic acid with a viscosity-average molecular weight of 48,000, put it in a three-neck bottle, add a mixed solvent of 600mL of dichloromethane and 800mL of methanol, heat to reflux, and after the solid is completely dissolved, cool down slightly, the liquid is slightly cloudy, and then Using a peristaltic pump under heating and reflux conditions, add 600mL of methanol dropwise at a rate of 3mL / min. During the dropping process, control the stirring speed at 100-150rpm. After the dropwise addition is completed, pour 400mL of methanol to dilute. The filter cake was washed, dried and passed through a 100-mesh sieve to obtain 28.5 g of poly-L-lactic acid microparticles with a particle size of D90=102.3 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com