Metal surface coating composition as well as preparation method, spraying method and application thereof

A technology of metal coating and composition, applied in the field of metal surface coating composition and preparation thereof, can solve the problems of large porosity of metal coating, electric breakdown spraying efficiency, etc., so as to improve the barrier performance and increase the carrying charge volume, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of a metal surface coating composition, the composition is used for spraying on the metal surface and can decorate and protect the metal surface, comprising the following steps:

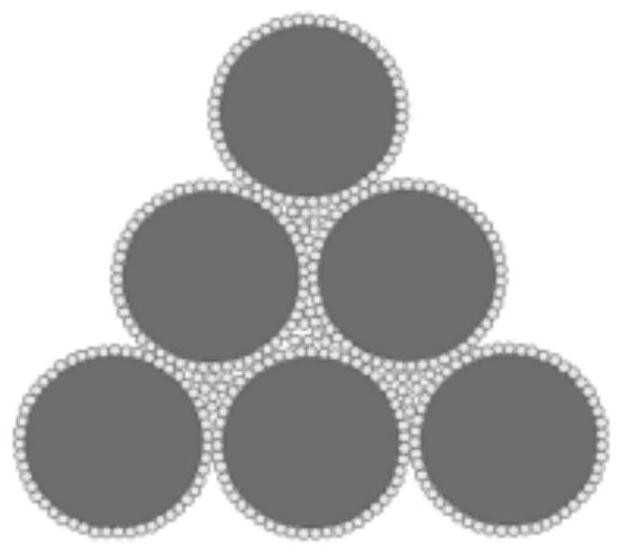

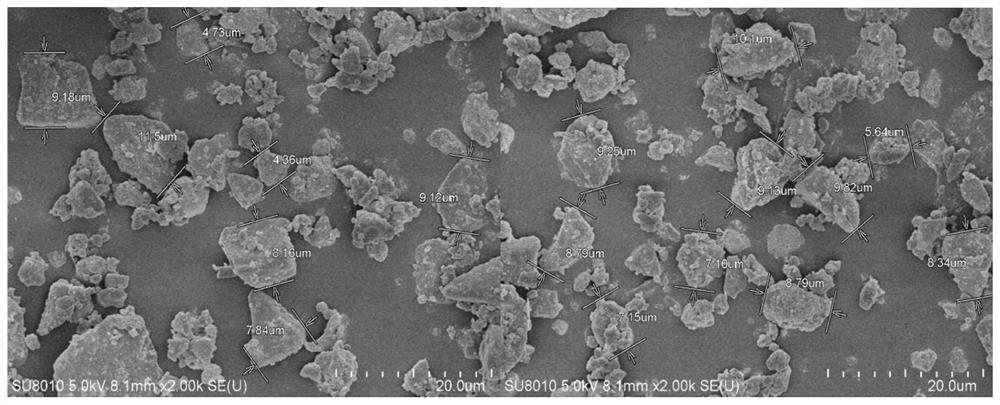

[0032] (1) High polymer, inorganic matter and auxiliary agent are pulverized to obtain high polymer powder particles, inorganic powder particles and auxiliary agent powder particles, and the high polymer powder particles and auxiliary agent powder particles are micron-sized powder particles, so The inorganic powder particles include nanoscale powder particles;

[0033] (2) Mix high polymer powder particles, inorganic powder particles and additive powder particles, and the mixing can be realized by existing mixers;

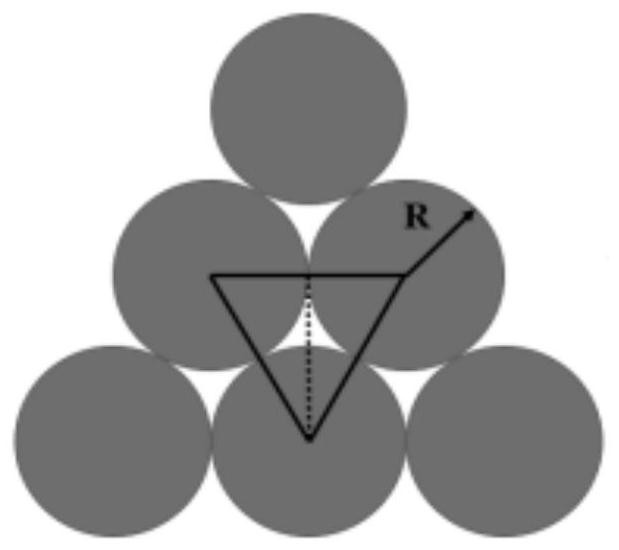

[0034] (3) Mechanically kneading the mixed polymer powder particles, inorganic powder particles and additive powder particles to form physically bonded microsphere particles. The mechanical kneading can be realized by existi...

Embodiment 1

[0043] The composition of material proportioning according to mass parts is as follows:

[0044] Bisphenol A type epoxy resin 100 parts, methyl phenyl silicone resin 0 parts, 50-2000nm Al 2 o 3 Particle 1 part, 10-70nm SiO 2 1 part of particles, 1 part of cyanamide SH-500A curing agent, 1 part of polyacrylic acid leveling agent, 0.1 part of silane coupling agent KH-550, 0.1 part of bisphosphite antioxidant, 5.0-40.0 μm mica powder 0 copies. Among them, bisphenol A epoxy resin and methylphenyl silicone resin belong to high polymer powder particles, and their particle diameters are both 5-10 microns. Polyacrylic acid leveling agent, silane coupling agent KH-550 type, dicyandiamide SH-500A type curing agent and phosphite antioxidant belong to auxiliary powder particles, and their particle diameters are all 5-10 microns. According to the above-mentioned preparation method, the above-mentioned ingredients are prepared into a metal surface coating composition. In other examples...

Embodiment 2

[0046] The composition of material proportioning according to mass parts is as follows:

[0047] 90 parts of bisphenol A epoxy resin, 30 parts of methyl phenyl silicone resin (polysiloxane), 50-2000nm Al 2 o 3 Particles 2 parts, 10-70nm SiO 2 2 parts of granule, 2 parts of dicyandiamide SH-500A curing agent, 2 parts of polyacrylic acid leveling agent, 0.2 part of silane coupling agent KH-550, 0.3 part of phosphite antioxidant, 5.0-40.0μm mica powder 10 servings.

[0048] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com