Compound stabilizer of tire repair glue solvent, preparation method of compound stabilizer and normal-temperature vulcanized tire repair glue

A compound stabilizer and room temperature vulcanization technology, which is applied in the field of tire repair, can solve the problems that the storage stability of tire repair glue cannot meet the market demand, reduce the adhesive force of tire repair glue, etc., and meet the requirements of tire repair, prolong the storage period, The effect of slowing down the speed of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

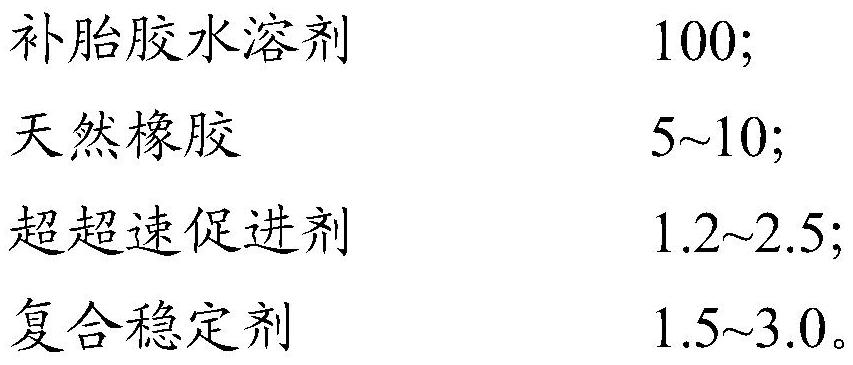

[0033] The application provides a normal temperature vulcanized tire sealant, comprising the following steps:

[0034] Add 100 kg of dichloroethylene, 0.40 kg of diethylamine, 0.40 kg of diisopropylamine, 0.50 kg of 2-hydroxy-4-n-octyloxybenzophenone, 0.30 kg of tetrahydrofuran and 0.80 kg of cyclohexanol into a closed stirring device. Oxychloropropane, stirred for 0.5 hours; 6 kg of constant viscose natural rubber CV60 was cut into small pieces and added to the above solvent, and after stirring for 10 hours, 0.2 kg of tetraethylthiuram disulfide (TETD) and 0.6 kg of disulfide were added. Zinc ethyl dithiocarbamate (ZDEC) and 0.6 kg of zinc ethyl phenyl dithiocarbamate (PX) accelerator, stirred for 2 hours, stopped stirring, took a sample for testing and recorded the rotational viscosity value of the sample, packed in jars, and marked For sample 1.

Embodiment 2

[0036] The application provides a normal temperature vulcanized tire sealant, comprising the following steps:

[0037] Add 100 kg of dichloroethylene into a closed stirring device, add 0.20 kg of triethylamine and 0.70 kg of diisopropylamine, 0.40 kg of N-(2-ethoxyphenyl)-N'-(2-ethylphenyl )-oxalamide, 0.40 kg of tetrahydrofuran and 0.90 kg of 2,6-di-tert-butyl-4-methylphenol, stirred for 0.5 hour; 6 kg of constant viscose natural rubber CV60 was cut into small pieces and added to the solvent, stirred After 10 hours, 0.2 kg of tetraethylthiuram disulfide (TETD), 0.6 kg of zinc diethyldithiocarbamate (ZDEC) and 0.6 kg of zinc ethylphenyldithiocarbamate (PX) were added Accelerator, stir for 2 hours, stop stirring, take a sample for testing and record the rotational viscosity value of the sample, put it in a jar, and mark it as sample 2.

Embodiment 3

[0039] The application provides a normal temperature vulcanized tire sealant, comprising the following steps:

[0040] Add 100 kg of trichlorethylene, 0.40 kg of triethylamine, 0.60 kg of diisopropylamine, 0.35 kg of N-(2-ethoxyphenyl)-N'-(2-ethylphenyl )-oxalamide, 0.55 kg of epichlorohydrin and 0.50 kg of 2,6-di-tert-butyl-4-methylphenol, stirred for 0.5 hour; 6 kg of constant viscose natural rubber CV60 was cut into small pieces and added to the solvent After stirring for 10 hours, add 0.2 kg of tetraethylthiuram disulfide (TETD), 0.6 kg of zinc diethyldithiocarbamate (ZDEC) and 0.6 kg of zinc ethylphenyldithiocarbamate (PX) Accelerator, stir for 2 hours, stop stirring, take a sample for testing and record the rotational viscosity value of the sample, put it in a jar, and mark it as sample 3.

[0041] According to the preparation method of Example 1, dichloroethylene-only, constant-viscosity natural The glue of CV60 and dithiocarbamate accelerator is marked as the compari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com