Environment-friendly polyolefin hot melt adhesive for cigarettes and preparation method thereof

A hot-melt adhesive and polyolefin technology, applied in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve problems such as poor sealing, high viscosity, and slow curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

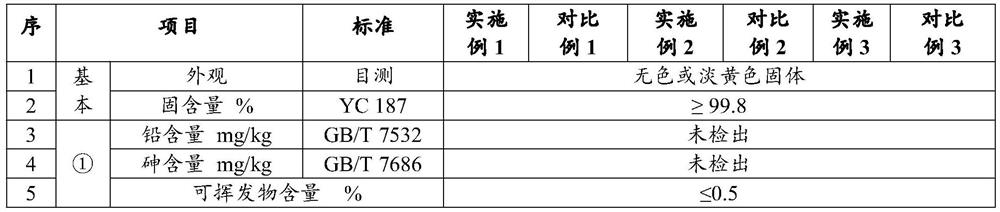

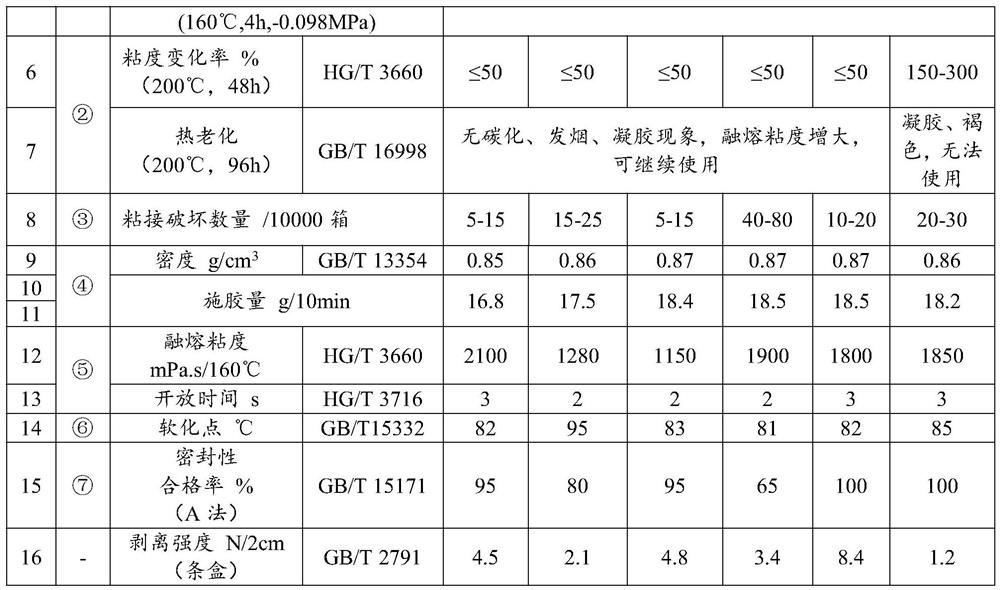

Examples

Embodiment 1

[0052] A preparation method of hot melt adhesive, comprising the steps of:

[0053] (1) Add raw materials (see Table 1) into the container, heat and stir at a stirring speed of 20r / min, and heat until the temperature of the material remains at 95°C;

[0054] (2) After adding the raw materials, raise the temperature to 140°C, the stirring speed is not lower than 100r / min, turn on the vacuum pressure reduction, the vacuum degree should not be lower than -0.08MPa, after 30 minutes of decompression, release the vacuum, and cool down to 140°C Discharge, leveling, granulation, packaging.

Embodiment 2

[0056] A preparation method of hot melt adhesive, comprising the steps of:

[0057] (1) Add raw materials (see Table 1) into the container according to the above-mentioned ratio of raw materials, heat and stir at a stirring speed of 30r / min, and heat until the material temperature is kept at 100°C;

[0058] (2) After adding the raw materials, raise the temperature to 150°C, the stirring speed is not lower than 100r / min, turn on the vacuum pressure reduction, the vacuum degree should not be lower than -0.08MPa, after 35 minutes of decompression, release the vacuum, and cool down to 145°C Discharge, leveling, granulation, packaging.

Embodiment 3

[0060] A preparation method of hot melt adhesive, comprising the steps of:

[0061] (1) Add raw materials (see Table 1) into the container according to the above-mentioned ratio of raw materials, heat and stir at a stirring speed of 50 r / min, and heat until the material temperature is kept at 105°C;

[0062] (2) After adding the raw materials, raise the temperature to 160°C, the stirring speed is not lower than 100r / min, turn on the vacuum to reduce the pressure, the vacuum degree should not be lower than -0.08MPa, after reducing the pressure for 40 minutes, release the vacuum, and cool down to 150°C Discharge, leveling, granulation, packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com