Dry microorganism barrier tester and dry microorganism barrier testing method for breathable packaging material

A packaging material and microorganism technology, which is applied in the methods of supporting/immobilizing microorganisms, biochemical equipment and methods, and methods of sampling biological materials, etc. It can solve the problem of affecting the number of colonies, low test efficiency, and uncontrollable shaking of samples taken manually. and other problems to avoid pollution, improve efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

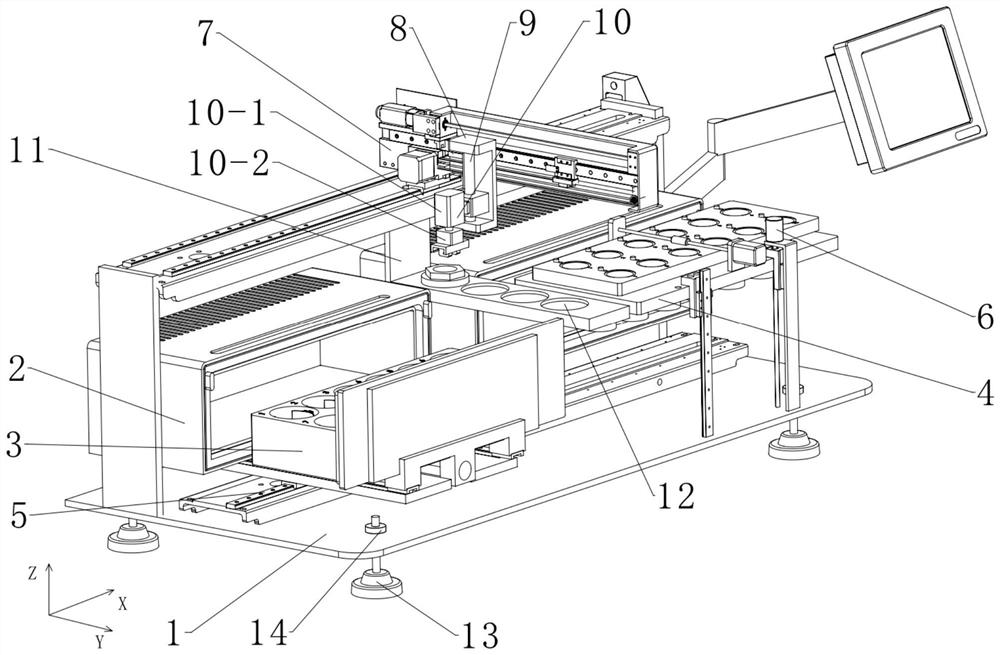

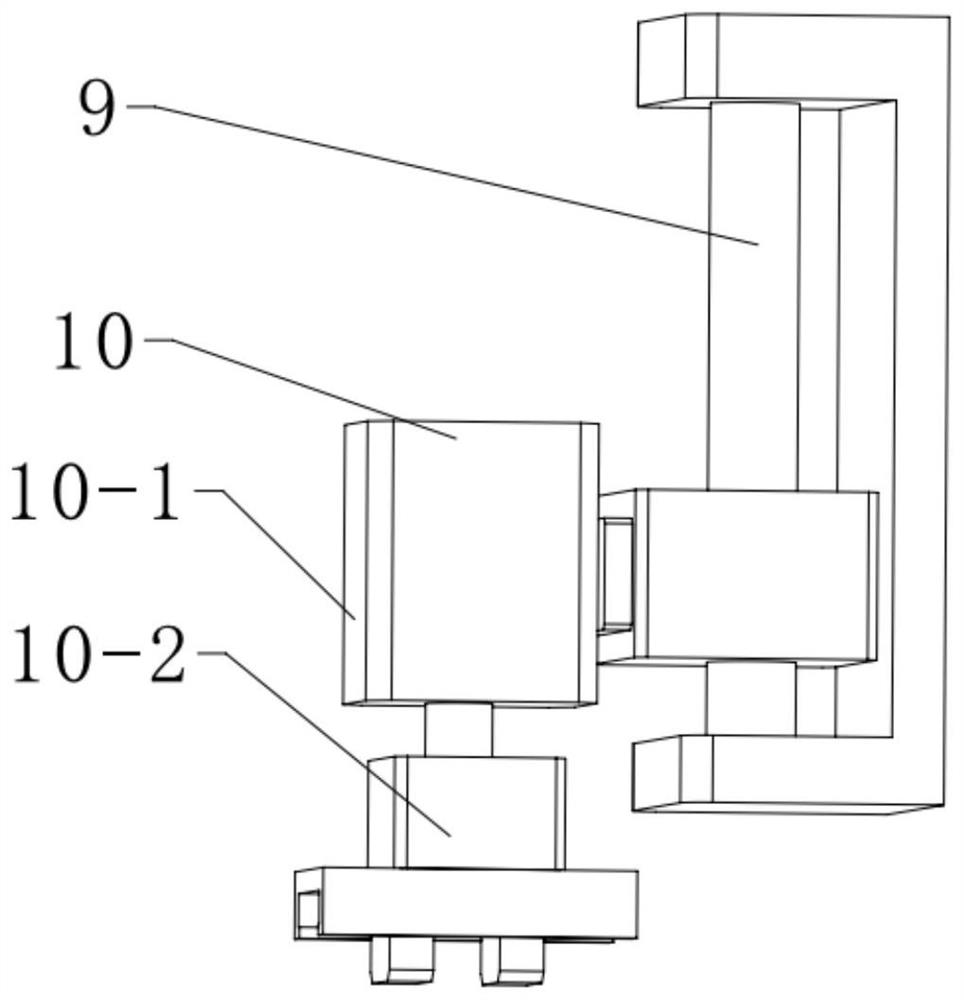

[0041] Such as Figure 1 to Figure 8 As shown, a dry microbial barrier tester for breathable packaging materials includes a bottom plate 1, a temperature control box 2, a dry powder dispensing module 4, a culture bottle carrier 3, a first linear module 5, and a second linear module 6 , the third linear module 7 and the bottle cap tightening device 8.

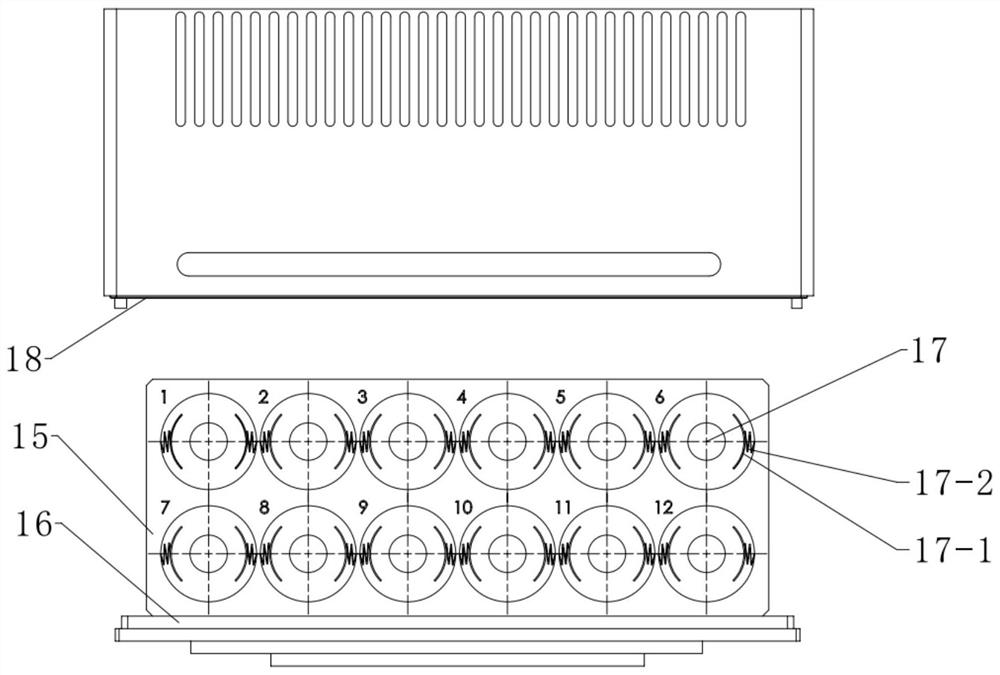

[0042] The temperature control box 2 is fixedly arranged on the bottom plate 1 and has an opening at the front. A sealing strip 18 is provided at the opening of the temperature control box 2. The culture bottle carrier 3 is located in front of the temperature control box 2. The dry powder separator The loading module 4 and the culture bottle carrier 3 are arranged side by side on the bottom plate 1 , and the culture bottle carrier 3 can be inserted into the temperature control box 2 .

[0043] The first linear m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap