Fire monitor motor driving and protecting circuit

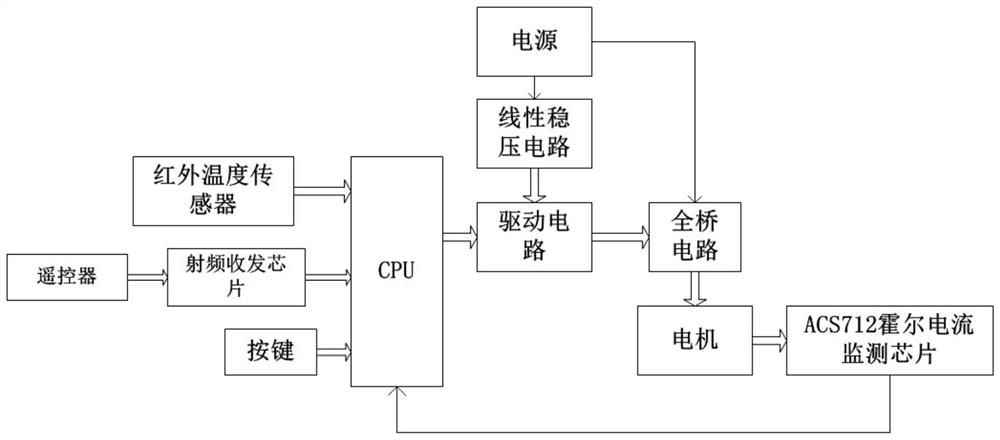

A motor drive and protection circuit technology, applied in emergency protection circuit devices, electric components, DC motor rotation control and other directions, can solve problems such as driver burnout, fire monitor stuck, motor burnout, etc. The effect of distance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

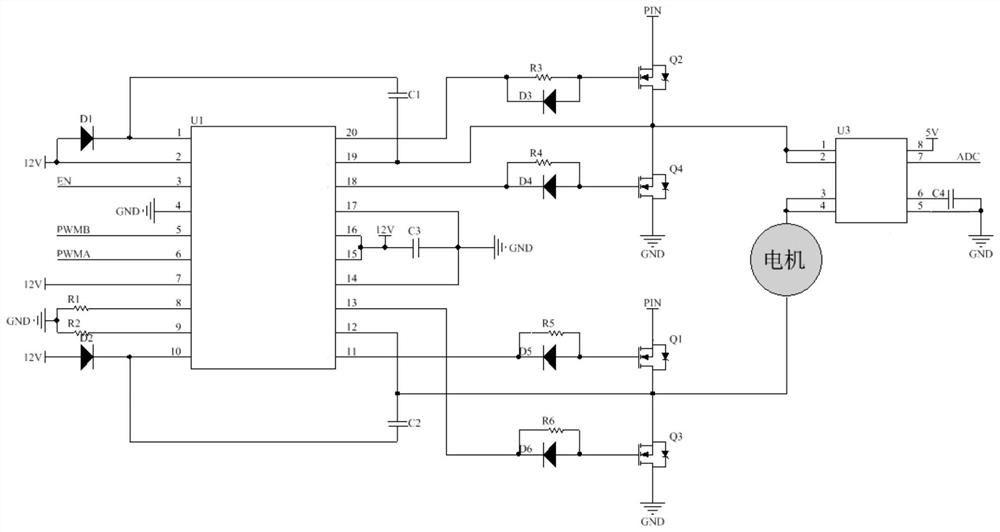

[0030]Such asfigure 2 The drive protection circuit diagram provided by the present invention, the H full bridge main circuit consists of the MOSFET of Q1, Q2, Q3, Q4 IRF3205PBF, and the input voltage of the main circuit is 24V, Q1, Q3 to receive the positive connection with the load motor. The Q2 and Q4 are connected to the load motor negative connection. Among them, IRF3205PBF is a HexFET N channel power MOSFET with extremely low on-resistance and rapid switching performance.

[0031]The driving signal of the four switch tubes in the main circuit achieves, Q1, Q3, the gate of Q1, Q3, and the gate of Q2, Q4 are connected to the entire bridge, respectively, and the gate of Q2, Q4, respectively, with the full bridge driver HIP4081A U1. The output pins 20 and 18 of the driver U1 are connected, and one gate resistance is connected between the gate and the full bridge driver, and a diode, that is, the gate connection of Q1 is connected to the gate resistance. The R4 and D4 of R6 and D3, Q4 ...

Embodiment 2

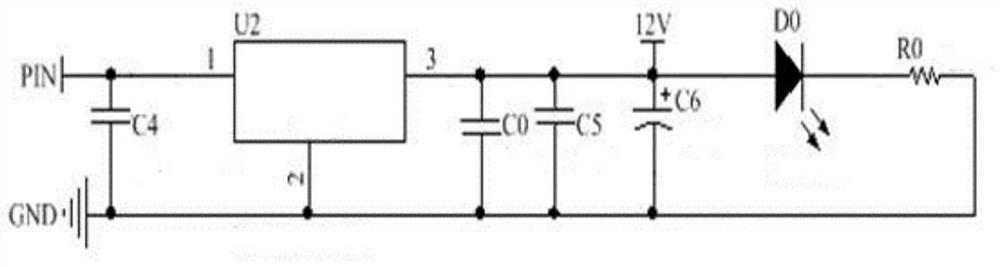

[0039]On the basis of the first embodiment, in order to ensure the normal operation of the full bridge driver U1, the MC7812 power supply regulator chip U2 is designed to provide a working voltage 12V for the driving circuit, such asimage 3 As shown, the input voltage of the linear regulator circuit is 24V, that is, the PIN interface input 24V voltage, the input is provided with one end of the input capacitance C4, C4, 1 pin connected to the MC7812 power supply regulator chip U2, one end and 2 pin ground Connection, there is also a capacitor C0, C5, and C6 between the 3-pin and 2 pins. For filtering and regulating, the circuit output 12V regulated power supply, the output terminal of the linear regulator circuit is connected in parallel with a light emitting diode D0. And the output voltage positive electrode of the light-emitting diode D0 and the output voltage of the linear regulator circuit is connected, the cathode is connected to one end of the partial pressure resistance, and ...

Embodiment 3

[0042]On the basis of Example 1, ifFigure 5 As shown, in the process of rotation of the motor in the real-time monitoring, the working condition detection problem when the motor is blocked, and when the motor is working, the motor current is monitored by the Hall current monitoring the chip in real time. In the present embodiment, when the motor current is less than 3A, the motor is operating normally; when the motor current is greater than 10A, the motor is blocked, which is the protective motor and the driving circuit. When the motor current reaches 7A, by changing the PWM pulse width, limit input The voltage of the motor is thus realized current limitation. If the current continues to exceed 7A, and the duration reaches 3s, the PWM input is cut off, and the power input of the motor is turned off to achieve the purpose of the protection motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com