Oyster preservation method

A preservation method, technology of oysters, applied in the direction of preservation of meat/fish with chemicals, preservation of meat/fish by radiation/electrical treatment, preservation of food ingredients as antimicrobial, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

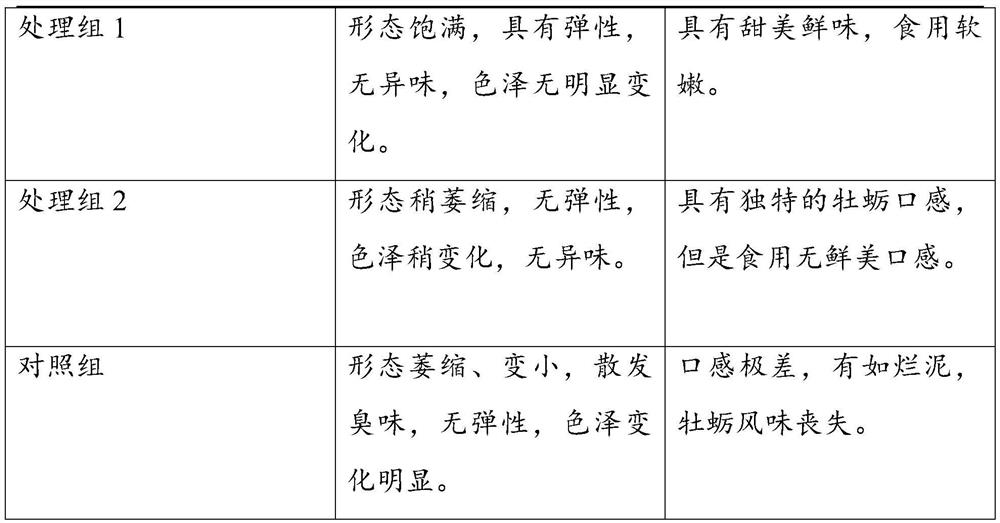

Examples

Embodiment 1

[0044] A fresh-keeping method for oysters, comprising the following steps:

[0045] (1) Open the shell and take the meat

[0046] Open the shell of the oyster and take out the meat, wash it with clean water;

[0047] (2) rinse

[0048] The oyster meat obtained in step (1) was rinsed in the rinsing solution for 8 minutes; the rinsing solution included the following raw materials in parts by weight: 0.35 parts of tea polyphenols, 1 part of sodium chloride, 0.5 parts of citric acid, 0.2 parts of polyphosphate, 5 parts trehalose.

[0049] (3) Ultrasonic treatment

[0050] The oyster meat obtained in step (2) was subjected to ultrasonic treatment; the ultrasonic treatment parameters were set as: 175W, 25KHz; the ultrasonic treatment method was: ultrasonic for 1 min, pause for 1 min, and repeated 5 times in total.

[0051] (4) Photodynamic sterilization

[0052] The oyster meat that step (3) obtains is put into curcumin, taraporfin sodium (food grade, purity is more than 95%) soa...

Embodiment 2

[0054] A fresh-keeping method for oysters, comprising the following steps:

[0055] (1) Open the shell and take the meat

[0056] Open the shell of the oyster and take the meat, wash it with water;

[0057] (2) rinse

[0058] The oyster meat obtained in step (1) was rinsed in the rinse solution for 12 minutes; the rinse solution included the following raw materials in parts by weight: 0.45 parts of tea polyphenols, 2 parts of sodium chloride, 0.75 parts of citric acid, 0.25 parts of polyphosphate, 7 trehalose.

[0059] (3) Ultrasonic treatment

[0060] The oyster meat obtained in step (2) was subjected to ultrasonic treatment; the ultrasonic treatment parameters were set as: 225W, 30KHz; the ultrasonic treatment method was: ultrasonic for 1 min, pause for 1 min, and repeated 7 times in total.

[0061] (4) Photodynamic sterilization

[0062] The oyster meat that step (3) obtains is put into curcumin, taraporfin sodium (food grade, purity is more than 95%) soaked in the sol...

Embodiment 3

[0064] A fresh-keeping method for oysters, comprising the following steps:

[0065] (1) Open the shell and take the meat

[0066] Open the shell of the oyster and take the meat, wash it with water;

[0067] (2) rinse

[0068] The oyster meat obtained in step (1) was rinsed in the rinse solution for 10 minutes; the rinse solution included the following raw materials in parts by weight: 0.4 part of tea polyphenols, 1.5 parts of sodium chloride, 0.625 parts of citric acid, 0.225 parts of polyphosphate, 6 trehalose.

[0069] (3) Ultrasonic treatment

[0070] The oyster meat obtained in step (2) was subjected to ultrasonic treatment; the ultrasonic treatment parameters were set to: 200W, 28KHz; the ultrasonic treatment method was: ultrasonic for 1min, pause for 1min, and repeated 6 times in total.

[0071] (4) Photodynamic sterilization

[0072] The oyster meat that step (3) obtains is put into curcumin, taraporfin sodium (food grade, purity is more than 95%) soaked in the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com