3D printed bone connecting rod system

A 3D printing and connecting rod technology, applied in 3D printing, femur, bone implants, etc., can solve the problems of unsustainable decompression, slow bone growth, and unstable fixation of porous tantalum rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

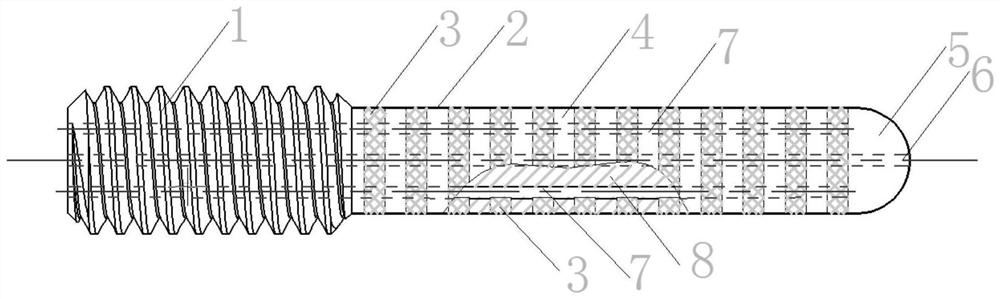

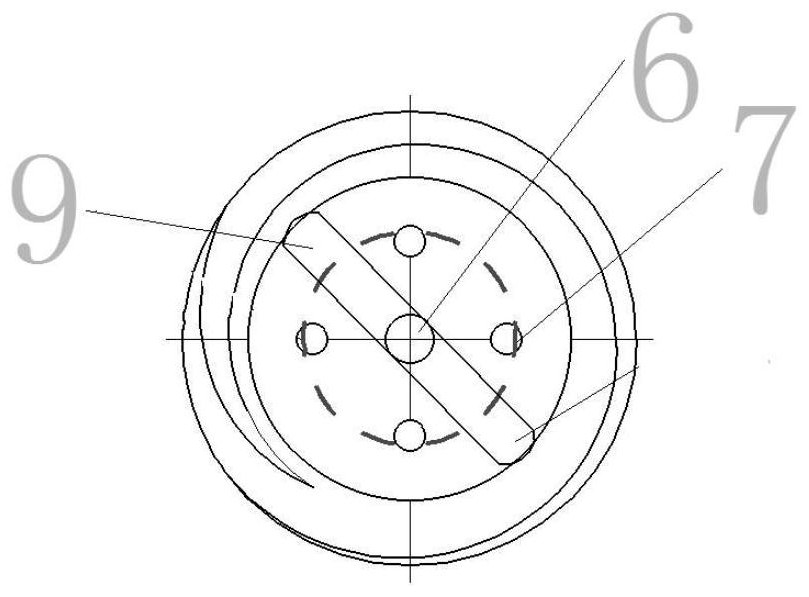

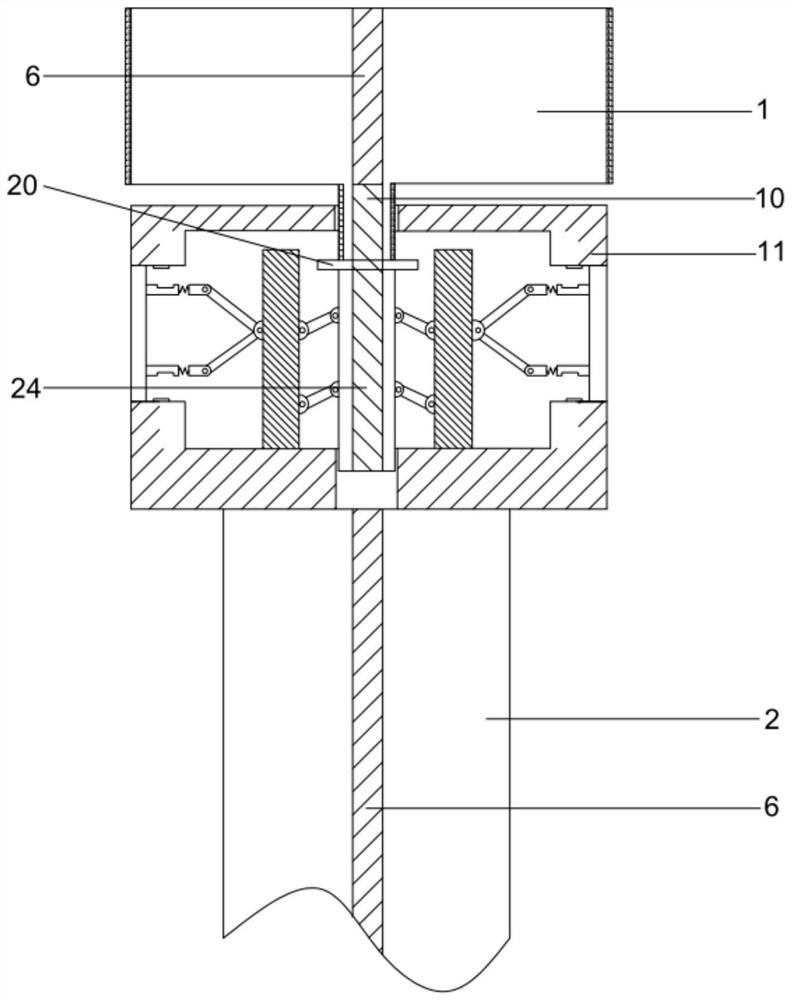

[0050] The purpose of this embodiment is to provide a 3D printed bone connecting rod system, refer to Figure 1-Figure 2 , comprising a bone connecting rod body, said bone connecting rod body comprising: a threaded section-1, a cylindrical section 2 and a spherical section 5 arranged in sequence, a through-threaded section-1, a cylindrical section arranged in the center of the 3D printed bone connecting rod body 2 and the through hole 6 of the spherical section 5;

[0051] The 3D printed bone connecting rod body also includes a number of nutrient holes 7 passing through the threaded section-1 and the cylindrical section 2; the cylindrical section 2 includes alternately arranged trabecular bone areas 3 and solid areas 4; The nutrition holes 7 are arranged symmetrically around the through-hole 6 , and several nutrition holes 7 intersect with the trabecular bone area 3 to provide nutrition for the trabecular bone area 3 . The bone connecting rod is made by 3D printing, and the m...

Embodiment 2

[0057] A 3D printed bone connecting rod system according to Embodiment 1, refer to Figure 1-Figure 2 , the threaded section one 1 is a solid structure that is osseolocked and fixed with the human cortex.

[0058] The beneficial effect of above-mentioned technical scheme is:

[0059] Thread section one 1 is a solid structure that is osseolocked and fixed with the human cortex, and has sufficient strength to ensure that external influences can reach the trabecular bone area 3 .

Embodiment 3

[0061] A kind of 3D printed bone connecting rod system according to embodiment one or two, refer to Figure 1-Figure 2 , the width of each of the trabecular bone regions 3 is 3-5 mm, the width of each of the solid regions 4 is 3-5 mm, and the pore diameter of the trabecular bone regions 3 is 100 μm-400 μm, and the distribution is uneven .

[0062] The beneficial effect of above-mentioned technical scheme is:

[0063] The width of each trabecular bone area 3 is 3mm-5mm to ensure absorbable bone mass, and the width of each solid area-4 is 3mm-5mm to ensure the locking strength between the grown bone of the human body and the solid area-4. The pore size of the trabecular bone area 3 is 100 μm-400 μm, which is unevenly distributed, which is conducive to faster and better ingrowth and absorption of bone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com