Autologous fat multi-component full-automatic separation, preparation and extraction device and method thereof

An extraction device and fully automatic technology, which is applied in the field of biomedical engineering, can solve the problems of low automation means and low utilization rate, and achieve the effects of high extraction efficiency, reduced possibility of pollution, and complete types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

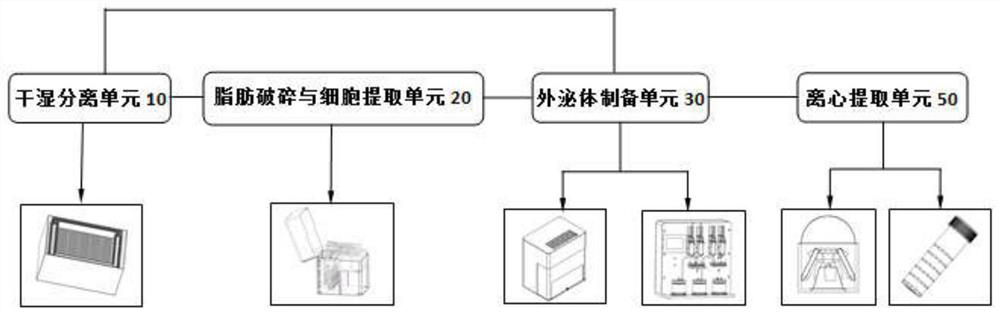

[0063] Such as Figure 1-20 As shown, the autologous fat multi-component automatic separation, preparation and extraction device includes a dry-wet separation unit 10, a fat crushing and cell extraction unit 20, an exosome preparation unit 30 and a centrifugal extraction unit 50, such as figure 1 As shown, the structure diagram of the corresponding unit is in the bottom box, which is convenient for corresponding understanding with the expanded description of each unit below.

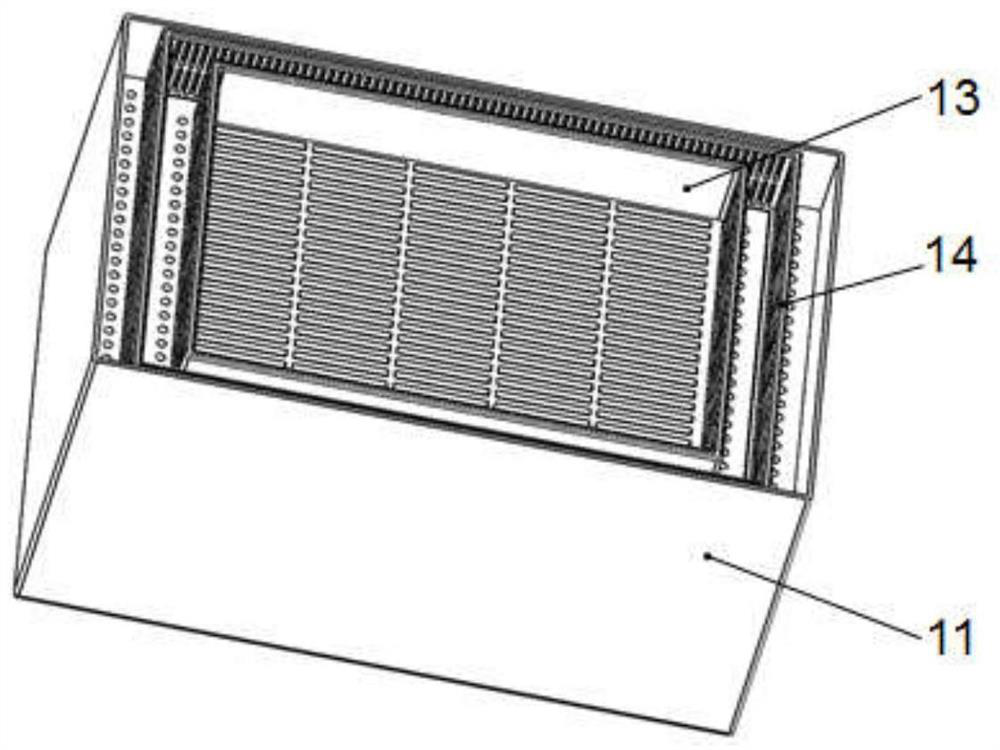

[0064] Such as Figure 2-7 As shown, the dry-wet separation unit 10 in this embodiment includes a separation box 11, and an upper cover 12 is fastened on the separation box 11. The separation box 11 and the upper cover 12 form a sealed box, which can be a square box. Two filter boxes are placed in the separation box 11 from top to bottom, namely the primary filter box 13 and the secondary filter box 14, and the separation box 11 is divided into three sections. In this embodiment, the primary filter box...

Embodiment 2

[0104] Such as Figure 14-18 As shown, based on Example 1, the difference between the autologous fat multi-component automatic separation, preparation and extraction device in this embodiment is that only the exosome preparation unit 30 is replaced, and the exosome preparation unit 30 adopts positive pressure filtration. Filtration. During the filtration process, the internal pressure can not only be kept constant, but also the filter membrane can be flushed with reciprocating flow to improve the filtration effect and shorten the filtration time. It can extract a large amount of exosomes and is suitable for commercial mass production.

[0105] In this embodiment, the exosome preparation unit 30 is a device for performing two-stage filtration of exosomes. Specifically, the exosome preparation unit 30 includes a bottom plate 443 on which a square casing and three tank holders 421 located outside the square casing and distributed side by side from left to right are installed on t...

Embodiment 3

[0113] Such as Figure 23 As shown, a multi-component automatic separation, preparation and extraction method of autologous fat, based on embodiment 1 or embodiment 2, is the process flow of the automatic multi-component separation, preparation and extraction method of autologous fat, and the multi-component automatic autologous fat The separation, preparation and extraction method comprises the following steps:

[0114] Step 1. Open the upper cover 12 of the dry-wet separation unit 10, inject the sucked autologous fat into the uppermost filter box, and separate the sucked autologous fat through different filter boxes to obtain connective tissue, Fats and mixed liquids.

[0115] Step 2. Put the connective tissue or fat obtained in step 1 into the second storage tank 227 of the fat crushing and cell extraction unit 20, start the power supply, and the cleaning solution in the first storage tank 226 is pumped in the first plunger pump 206 Enter the second storage tank 227 under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com