Rubber grinding machine

A grinding machine and rubber technology, used in grinding frames, grinding machine parts, grinding machines, etc., can solve the problems of low grinding quality, adverse human health, and affecting grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

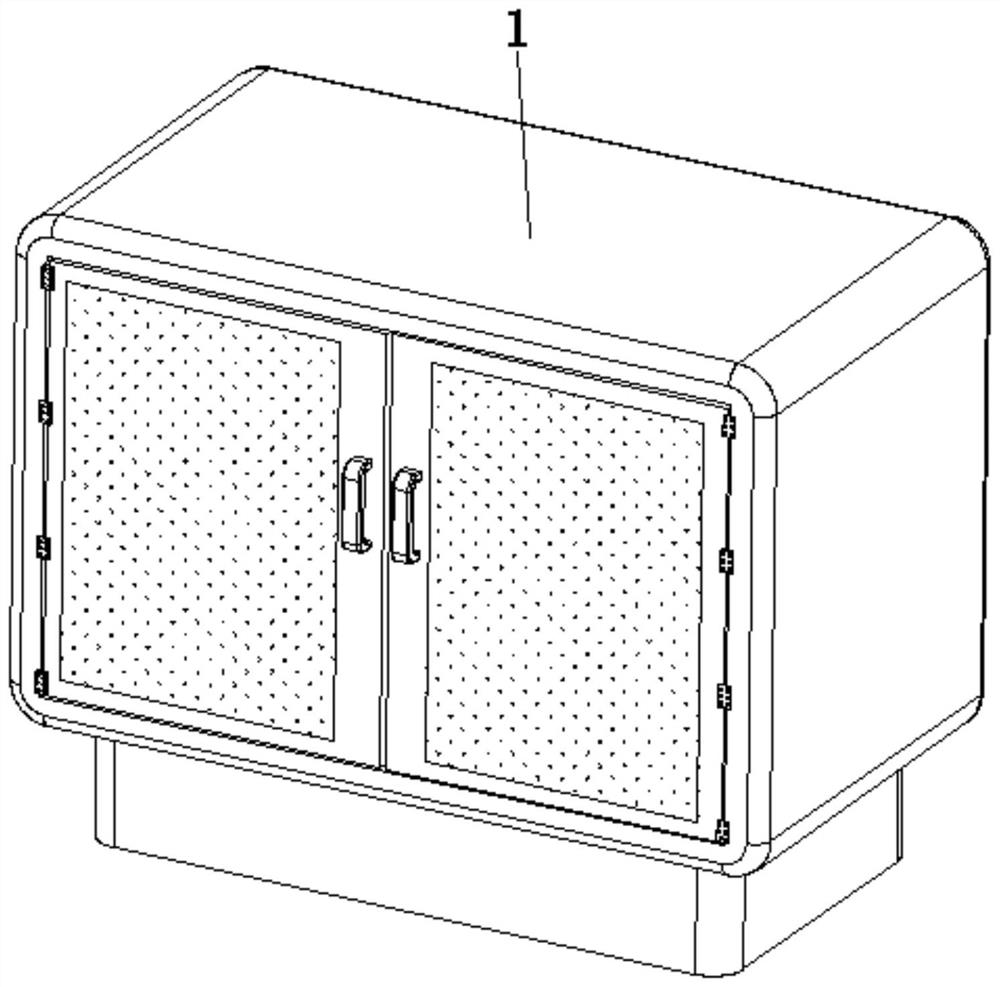

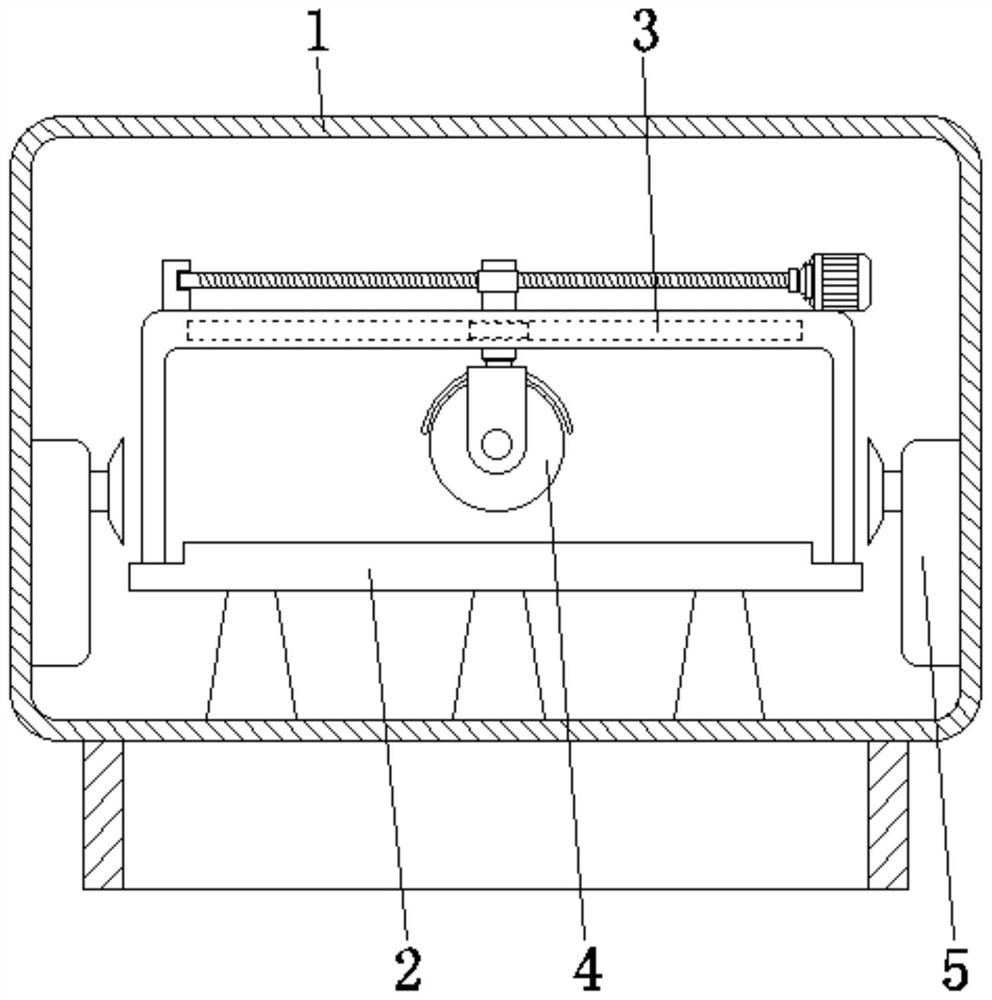

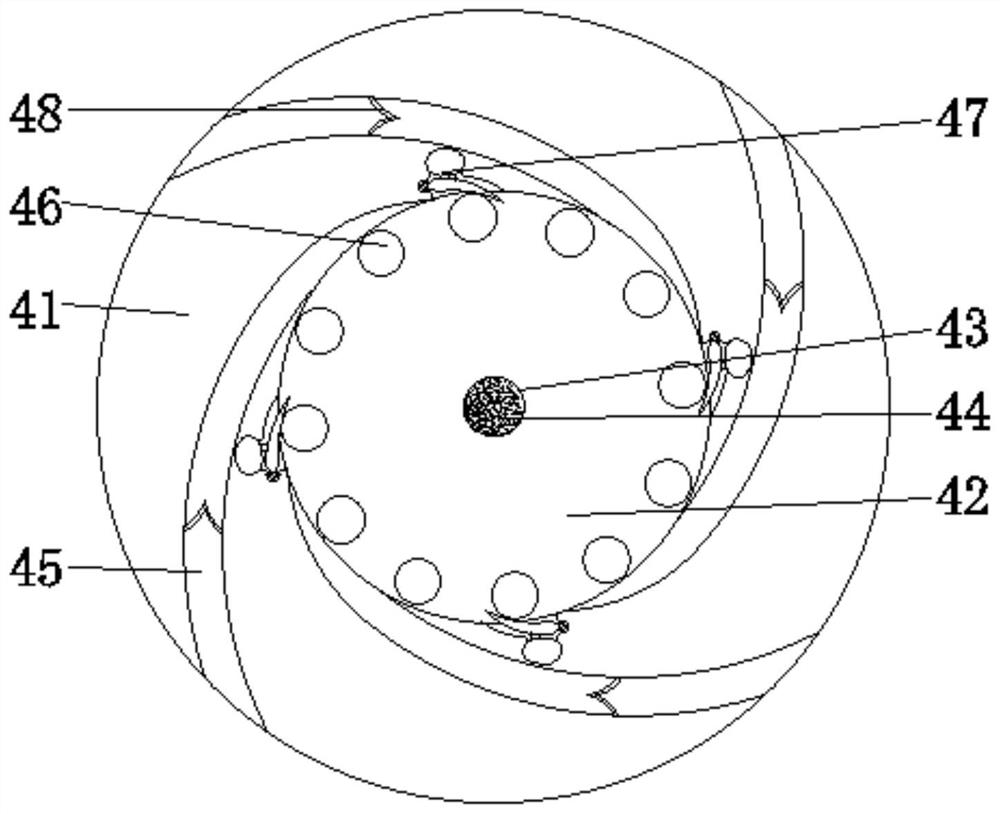

[0033] see Figure 1-7 , the present invention provides a technical solution: a rubber grinding machine, comprising a chassis 1, a workbench 2, a support drive mechanism 3, a grinding device 4, and a vacuum cleaner 5, the workbench 2 is fixed at the bottom center of the inner wall of the chassis 1, and the grinding device 4 is fixed on the top of the workbench 2 through the support drive mechanism 3, the vacuum cleaner 5 is fixed on both sides of the inner wall of the cabinet 1, and the grinding device 4 is provided with a grinding roller 41, a cylindrical inner cavity 42, an exhaust hole 43, a filter screen 44, and a flow guide Air channel 45, friction ball 46, dust removal device 47, filter device 48, cylindrical inner chamber 42 is set in the inner central position of grinding roller 41, exhaust hole 43 is opened in one end of grinding roller 41, filter screen 44 is fixed on the exhaust hole 43, the guide air passage 45 is set inside the grinding roller 41 and communicates ...

Embodiment example 2

[0038] The filtering device 48 is provided with an arc surface housing 481, a flow guide 482, a filter plate 483, an air inlet 484, and an air outlet 485. The flow guide 482 is fixed on one side of the surface of the arc surface housing 481, and the filter plate 483 is fixed In the inside of the curved shell 481 and the inside of the flow guide 482, the air inlet 484 and the air outlet 485 are respectively opened on the surface of the flow guide 482 and the surface of the curved shell 481, and are used to change the path of the air flow and If the speed is moderately reduced, the large particle dust can be filtered in time first, so as not to affect the subsequent collection of dust and avoid blockage.

[0039] When in use, first put the rubber to be polished on the workbench 2. At this time, the motor drives the grinding device 4 to rotate at a high speed, and is driven by the supporting drive mechanism 3 to perform grinding, and then the vacuum cleaner 5 is turned on for dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com