Catalytic production process of deuterated benzene

A production process, the technology of deuterated benzene, which is applied in the field of catalytic production process of deuterated benzene, can solve the problems such as the speed of catalyst addition is not reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Mix 500mL of benzene and 1000mL of heavy water, add 30g of platinum carbon, heat and stir in a closed reaction at 110°C for 12 hours, separate and distill to obtain the target product deuterated benzene;

[0049] Wherein, the platinum carbon is added at a rate as in Table 1, and the deuteration rate results of the final target product are shown in Table 1.

[0050] Table 1

[0051]

[0052]

[0053]As can be seen from the data in Table 1, the deuterium rate of the target product is related to the addition rate of platinum-carbon, and when the rate of addition of platinum-carbon is added at a rate of 15 to 35% / minute of the total weight, the deuterium rate of the target product is the highest. Both exceed 90%; while the addition rate of platinum carbon is too fast, such as sample 9, once platinum carbon is added completely, the deuterium rate of the target product is only 74%; the addition rate of platinum carbon is too slow, such as sample 1, with When adding...

Embodiment 2

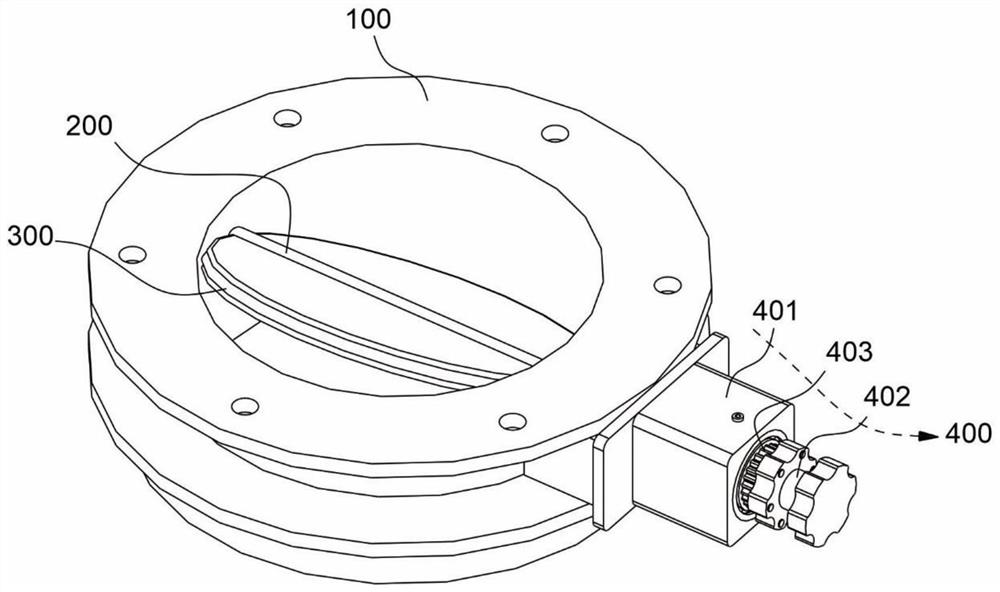

[0055] refer to Figure 1 to Figure 3 , is the first embodiment of the present invention. This embodiment provides a manual powder valve. Platinum carbon is added to the mixed solution of benzene and heavy water through the manual powder valve. The manual powder valve is specially designed for experiments. The manual powder valve controls the addition speed of platinum carbon to study the effect of the addition speed of platinum carbon to the mixed solution of benzene and heavy water on the deuteration rate of the final target product.

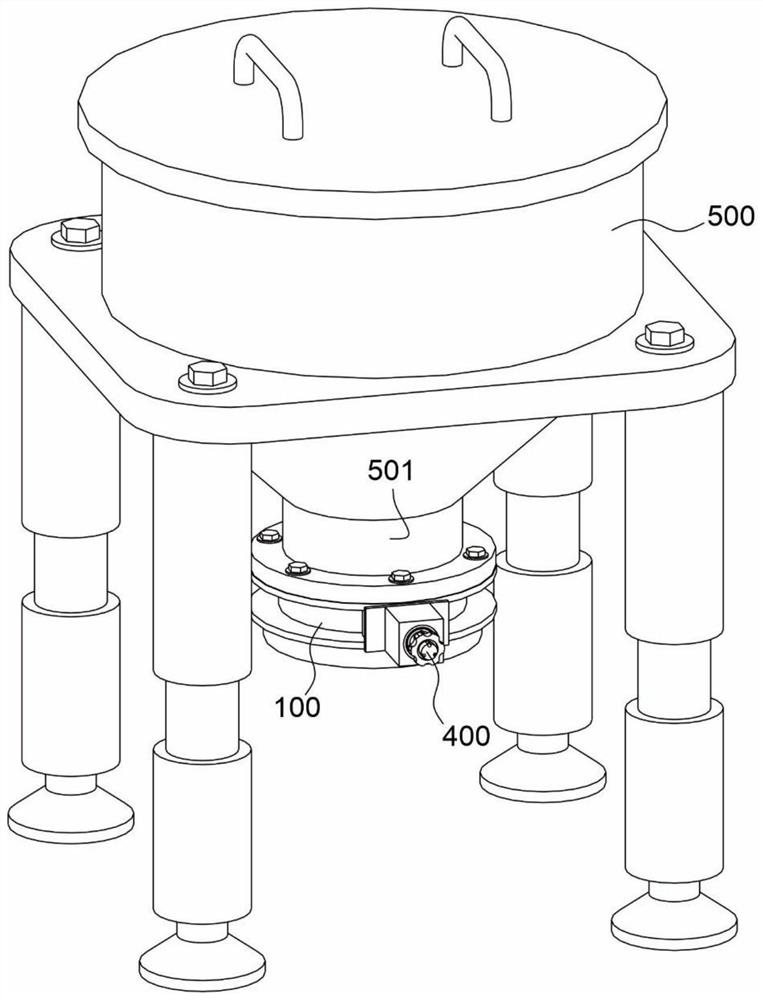

[0056] Specifically, such as figure 1 As shown, the manual powder valve is set at the discharge port 501 of the tank body 500, and the platinum carbon is stored in the tank body 500 in advance, and the discharge speed of the platinum carbon is controlled through the operation of the manual powder valve.

[0057] In this embodiment, the structure of the manual powder valve is similar to the butterfly valve in the prior art, which includes a va...

Embodiment 3

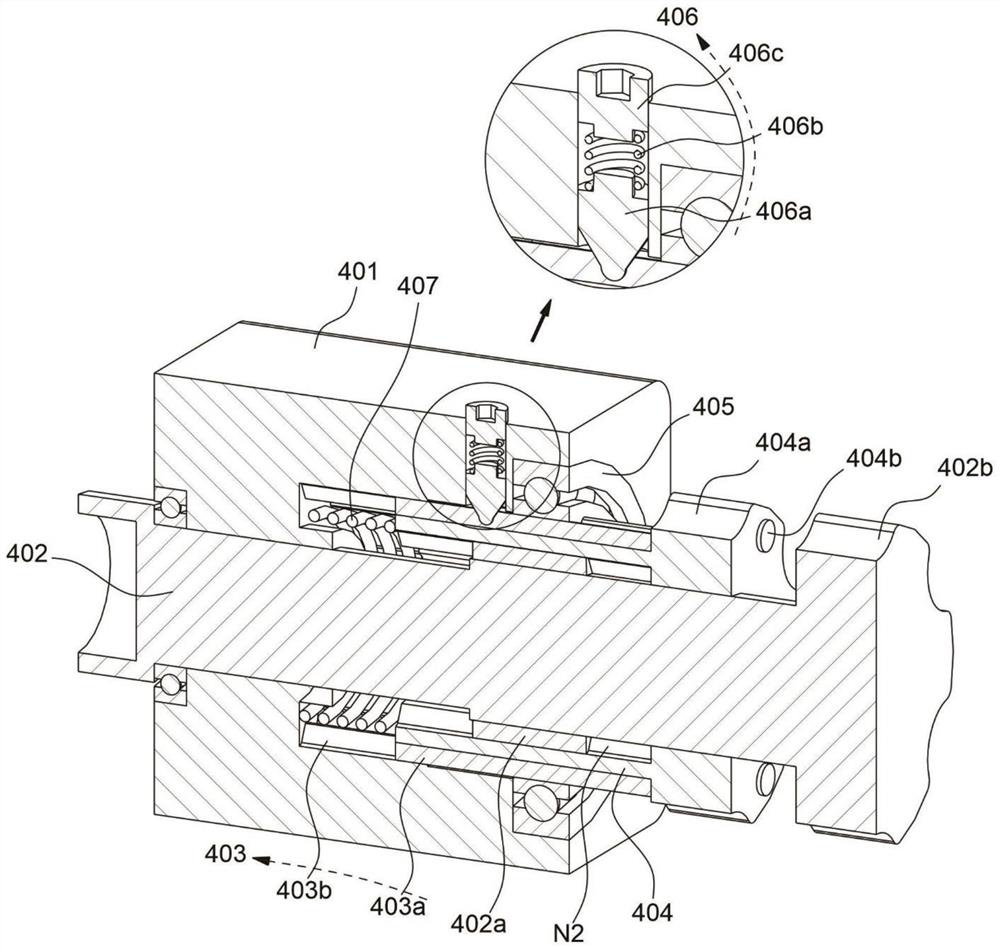

[0063] refer to Figure 2 to Figure 6 , this embodiment is different from the first embodiment in that: in order to facilitate the axial movement of the first connecting member 403a on the operating shaft 402, the first connecting member 403a is provided with a slide tube 404 sleeved on the outside of the operating shaft 402 , the first connecting piece 403a moves on the operating shaft 402 through the sliding tube 404, and the first connecting piece 403a can be moved axially conveniently by operating the sliding tube 404 to move;

[0064] Wherein, the support 401 is provided with an accommodating chamber N1 for accommodating the slide tube 404 and a through hole N4 for the operation shaft 402 to pass through. The inner diameter of the accommodating chamber N1 is larger than the inner diameter of the through hole N4. The rotating bearing connected, the operating shaft 402 passes through the through hole N4, and can rotate in the through hole N4 under the support of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com