Production method of cyclohexanone ketal perfume for daily cosmetics

A cyclohexanone ketal and production method technology, which is applied in the field of daily chemicals, can solve the problems of reduced catalytic activity, strong inorganic acid corrosion, and many side reactions, and achieves less catalyst consumption, improved dispersion, improved activity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

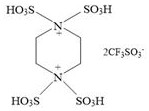

Image

Examples

Embodiment 1

[0028] A kind of preparation method that is used to produce the catalyst of cyclohexanone-1,3-butanediol ketal, is to realize by following specific steps:

[0029] (1) Mesoporous SnO 2 -TiO 2 preparation of

[0030] Dissolve titanyl sulfate, tin tetrachloride and CTAC in deionized water respectively, stir at room temperature for 15 min, then add urea to the above mixed solution and continue to stir for 15 min, then place the resulting mixture in a water bath at 90 °C Stirring treatment for 18h, the resulting product was filtered and washed to no Cl - After drying at 105°C for 16h, the obtained product was roasted at 550°C for 5h to obtain SnO 2 -TiO 2; The addition of the CTAC is 4wt% of the total weight of zirconyl chloride; the concentration of titanyl sulfate in the above mixed solution is 0.2mol / L; the concentration of substance of tin tetrachloride is 0.4mol / L ; The addition of urea is 20 times the amount of the total substance of titanyl sulfate and tin tetrachlorid...

Embodiment 2

[0040] A kind of preparation method that is used to produce the catalyst of cyclohexanone-1,3-butanediol ketal, is to realize by following specific steps:

[0041] (1) Mesoporous SnO 2 -TiO 2 preparation of

[0042] Dissolve titanyl sulfate, tin tetrachloride and CTAC in deionized water respectively, stir at room temperature for 15 min, then add urea to the above mixed solution and continue to stir for 15 min, then place the resulting mixture in a water bath at 90 °C Stirring treatment for 20h, the resulting product was filtered and washed to no Cl - After drying at 105°C for 16h, the obtained product was roasted at 550°C for 5h to obtain SnO 2 -TiO 2 ; The addition of the CTAC is 5wt% of the total weight of zirconyl chloride; the concentration of titanyl sulfate in the above mixed solution is 0.2mol / L; the concentration of substance of tin tetrachloride is 0.2mol / L ; The addition of urea is 20 times the amount of the total substance of titanyl sulfate and tin tetrachlori...

Embodiment 3

[0052] A kind of preparation method that is used to produce the catalyst of cyclohexanone-1,3-butanediol ketal, is to realize by following specific steps:

[0053] (1) Mesoporous SnO 2 -TiO 2 preparation of

[0054] Dissolve titanyl sulfate, tin tetrachloride and CTAC in deionized water respectively, stir at room temperature for 15 min, then add urea to the above mixed solution and continue to stir for 15 min, then place the resulting mixture in a water bath at 90 °C Stirring treatment for 24h, the resulting product was filtered and washed to no Cl - After drying at 105°C for 16h, the obtained product was roasted at 550°C for 5h to obtain SnO 2 -TiO 2 ; The addition of the CTAC is 6wt% of the total weight of zirconyl chloride; the concentration of titanyl sulfate in the above mixed solution is 0.4mol / L; the concentration of substance of tin tetrachloride is 0.2mol / L ; The addition of urea is 20 times the amount of the total substance of titanyl sulfate and tin tetrachlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com