Water-based modified polyurethane dispersion, application thereof and hair conditioner prepared from the same

A technology of polyurethane dispersion and hair conditioner, which is applied in the field of water-based modified polyurethane dispersion and its use and the hair conditioner prepared by it, can solve the problems of unsatisfactory hair antistatic effect and the like, and achieve the maintenance of normal colony balance and no appearance. Influence and reduce the effect of dandruff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

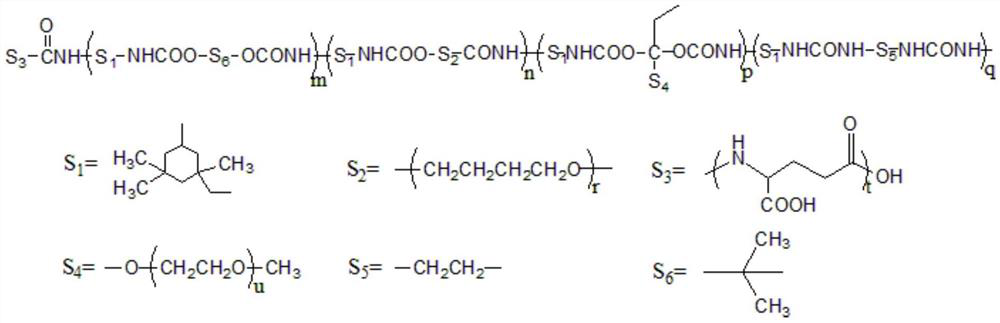

[0087] Example 1 Preparation of Waterborne Modified Polyurethane Dispersion-1

[0088]

[0089] Among them, m, n, p, q, r, t, u represent the number of repeating units,

[0090] m, n, p, q are independently selected from 0-20, m, n, p, q cannot be 0 at the same time, r is from 25-30, t is from 6, u is from 15-25.

[0091] Add 60g of (S1) IPDI (isophorone diisocyanate), 63.6g (S2) PTMEG2000 (polytetrahydrofuran ether glycol), 40g (S4) YmerTMN120 and 0.0662g (S9) BiCAT8108 catalyst, heat up to 80°C for 1 hour, cool down to 55°C, Add 11.8g (S6) neopentyl glycol and 36g (S7) acetone, raise the temperature to 75°C for reaction, take samples every 1h to measure NCO, until NCO reaches the theoretical value, stop the reaction.

[0092] Cool down to 55°C, add 108g (S7) acetone, cool down to 30°C, pour the prepared prepolymer into a dispersion cup, add 332g (S8) deionized water under high-speed shear conditions of 1500r / min, to obtain Aqueous polyurethane emulsion, then add 0.71...

Embodiment 2

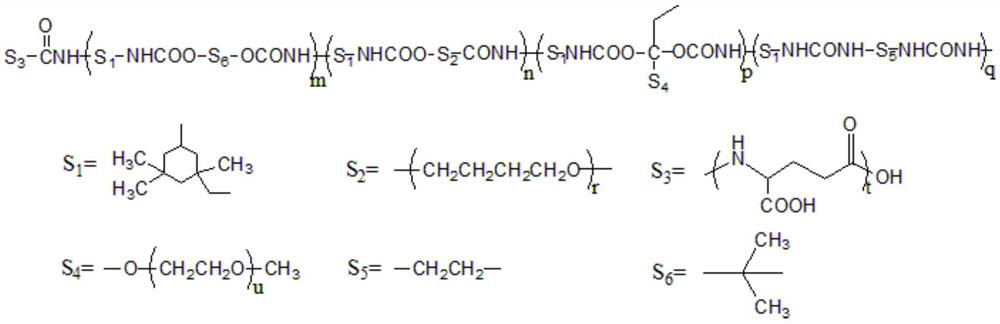

[0094] Example 2 Preparation of Waterborne Modified Polyurethane Dispersion-2

[0095]

[0096] Among them, m, n, p, q, r, t, u represent the number of repeating units,

[0097] m, n, p, q are independently selected from 0-20, m, n, p, q cannot be 0 at the same time, r is from 25-30, t is from 4, u is from 15-25.

[0098] Add 60g of (S1) IPDI (isophorone diisocyanate), 40g (S2) PTMEG2000 (polytetrahydrofuran ether glycol), 40g (S4) YmerTMN120 and 0.0585g (S9) BiCAT 8108 catalyst, heat up to 80°C for 1 hour, cool down to 55°C and add 11.6g (S6) neopentyl glycol and 31.32g (S7) acetone were heated to 75°C for reaction, and NCO was measured every 1 hour until NCO reached the theoretical value, and the reaction was stopped.

[0099]Cool down to 55°C, add 93.98g of acetone, cool down to 30°C, pour the prepared prepolymer into a dispersion cup, add 289g (S8) deionized water under high-speed shear conditions of 1500r / min to obtain water-based polyurethane Emulsion, then add ...

Embodiment 3

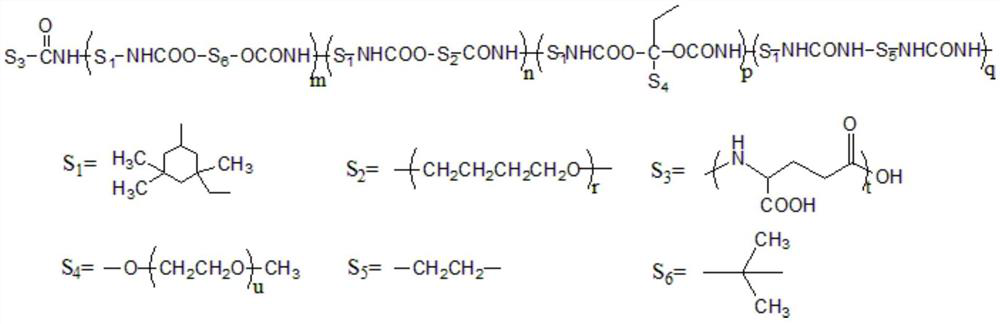

[0101] Example 3 Preparation of Waterborne Modified Polyurethane Dispersion-3

[0102]

[0103] Among them, m, n, p, q, r, t, u represent the number of repeating units,

[0104] m, n, p, q are independently selected from 0-20, m, n, p, q cannot be 0 at the same time, r is from 25-30, t is from 1, u is from 15-25.

[0105] Add 60g of (S1) IPDI (isophorone diisocyanate), 50g (S2) PTMEG2000 (polytetrahydrofuran ether glycol), 40g (S4) YmerTMN120 and 0.0615g (S9) BiCAT 8108 catalyst, heat up to 80°C for 1 hour, cool down to 55°C and add 11.6g (S6) neopentyl glycol and 33.5g (S7) acetone were heated up to 75°C for reaction, and NCO was measured every 1 hour until NCO reached the theoretical value, and the reaction was stopped.

[0106] Cool down to 55°C, add 100g (S7) acetone, cool down to 30°C, pour the prepared prepolymer into a dispersion cup, add 307g (S8) deionized water under high-speed shear conditions of 1500r / min, to obtain Aqueous polyurethane emulsion, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com