Water-soluble gutter oil environment-friendly asphalt separant

A technology of waste oil and release agent, applied in coatings, anti-corrosion coatings, etc., can solve the problems of pollution, unfavorable cleaning, unfavorable asphalt mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

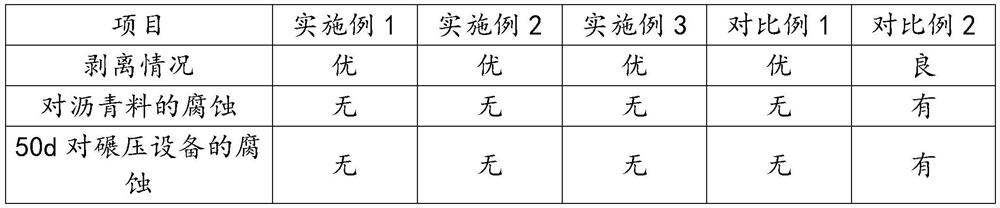

Examples

Embodiment 1

[0036] A water-soluble waste oil environment-friendly asphalt release agent, comprising the following raw materials in parts by weight:

[0037] 100 parts of deionized water, 20 parts of waste oil, 5 parts of glycerin, 5 parts of simethicone, 808 parts of Tween, 6010 parts of Span, 1 part of rust inhibitor, 3 parts of talcum powder, 0.6 parts of sodium benzoate and mass fraction 20 parts of 10% polyvinyl alcohol;

[0038] The water-soluble waste oil environment-friendly asphalt release agent is prepared through the following steps:

[0039] Step 1: Set the temperature to 50°C, mix deionized water, waste oil, glycerin, simethicone, Tween 80 and Span 60, and stir at a speed of 300r / min for 15 minutes to obtain the first mixed solution;

[0040] In the second step, the antirust agent, talcum powder, sodium benzoate, mass fraction of 10% polyvinyl alcohol and the first mixed solution are transported to the colloid mill emulsifier, sheared and blended until no agglomeration, no fl...

Embodiment 2

[0059] A water-soluble waste oil environment-friendly asphalt release agent, comprising the following raw materials in parts by weight:

[0060] 150 parts of deionized water, 30 parts of waste oil, 10 parts of glycerin, 7 parts of simethicone, 809 parts of Tween, 6011 parts of Span, 2 parts of antirust agent, 4 parts of talcum powder, 0.8 parts of sodium benzoate and mass fraction 25 parts of 10% polyvinyl alcohol;

[0061] The water-soluble waste oil environment-friendly asphalt release agent is prepared through the following steps:

[0062] Step 1: Set the temperature to 75°C, mix deionized water, waste oil, glycerin, simethicone, Tween 80 and Span 60, and stir at a speed of 300r / min for 18 minutes to obtain the first mixed solution;

[0063] In the second step, the antirust agent, talcum powder, sodium benzoate, mass fraction of 10% polyvinyl alcohol and the first mixed solution are transported to the colloid mill emulsifier, sheared and blended until no agglomeration, no ...

Embodiment 3

[0082] A water-soluble waste oil environment-friendly asphalt release agent, comprising the following raw materials in parts by weight:

[0083] 200 parts of deionized water, 40 parts of waste oil, 15 parts of glycerin, 8 parts of simethicone, 8010 parts of Tween, 6012 parts of Span, 3 parts of rust inhibitor, 5 parts of talcum powder, 1 part of sodium benzoate and the mass fraction 30 parts of 10% polyvinyl alcohol;

[0084] The water-soluble waste oil environment-friendly asphalt release agent is prepared through the following steps:

[0085] Step 1: Set the temperature to 80°C, mix deionized water, waste oil, glycerin, simethicone, Tween 80 and Span 60, and stir at a speed of 300r / min for 20 minutes to obtain the first mixed solution;

[0086] In the second step, the antirust agent, talcum powder, sodium benzoate, mass fraction of 10% polyvinyl alcohol and the first mixed solution are transported to the colloid mill emulsifier, sheared and blended until no agglomeration, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com