Anti-explosion centrifugal fan and anti-explosion method thereof

A technology of centrifugal fan and explosion-proof motor, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., and can solve problems such as unfavorable safety production, low fan safety, equipment and personnel injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

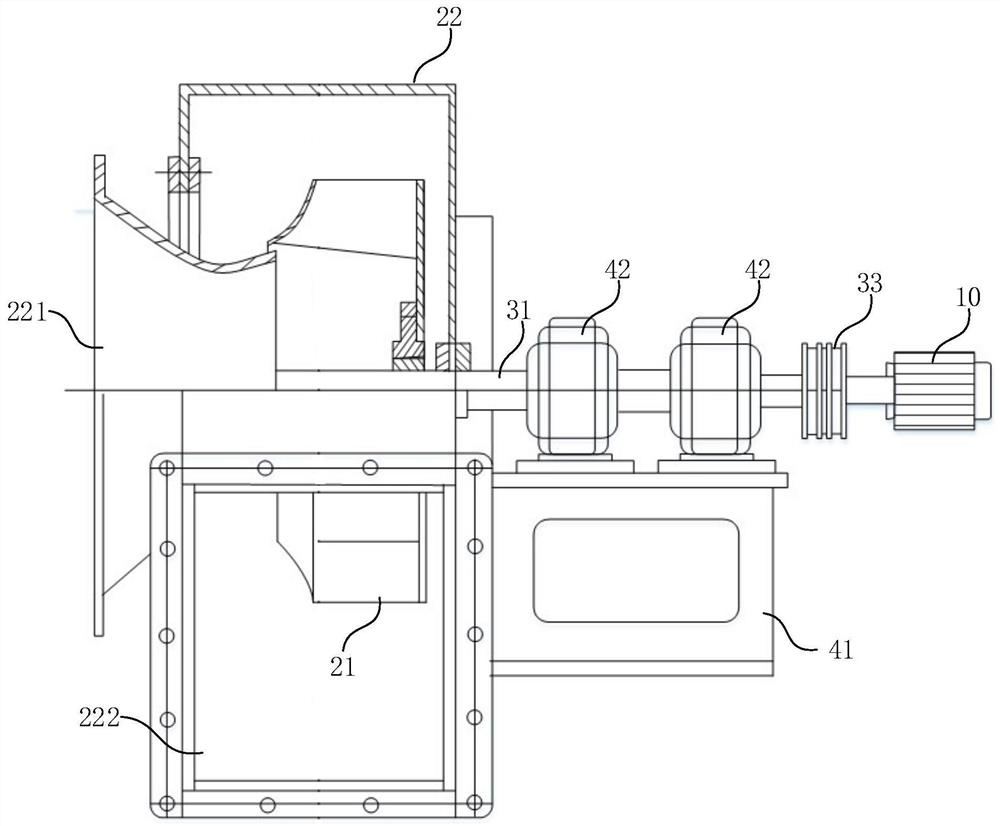

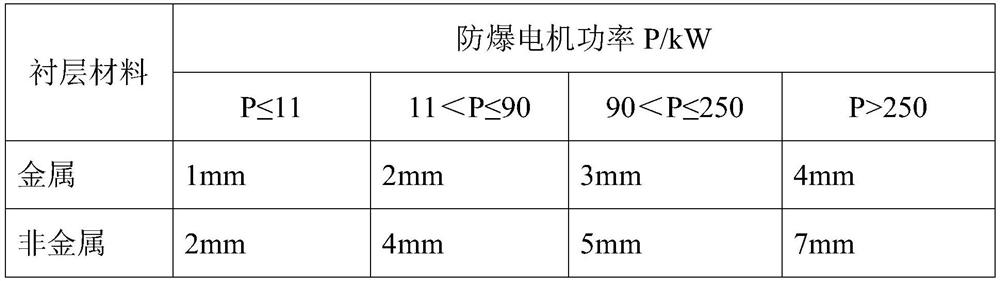

[0048] refer to figure 1 As shown, in the explosion-proof centrifugal fan of this embodiment, the electric power of the explosion-proof motor 10 is 5.5kW. The impeller 21 is made of 630 stainless steel, and its strength is 1.2 times the equivalent stress value of the maximum running speed. The casing 22 is made of 304 stainless steel and can withstand an impact pressure of 1.0 MPa through the impact test. The inner wall of the casing 22 is provided with a lining layer made of polytetrafluoroethylene with a thickness of 2mm. The axial and radial minimum one-sided gap between the impeller 21 and the casing 22 is 5 mm. The impeller 21 and the main shaft 31 are fixedly installed through a combination of a tapered bush and a flat key.

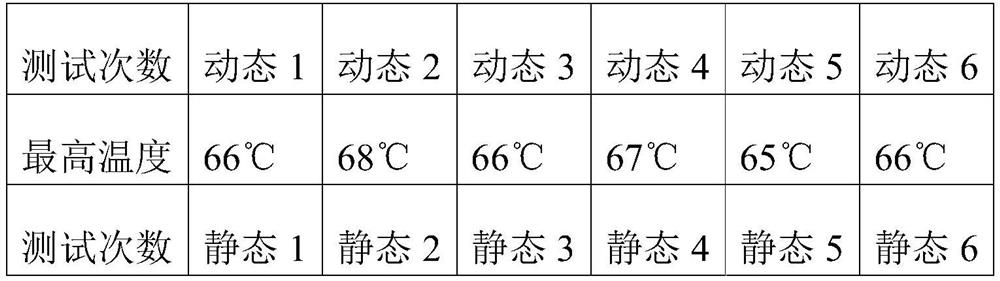

[0049] The explosion-proof centrifugal fan of this embodiment is subjected to a flame propagation test. The ethylene / air mixture is introduced into the test circuit pipeline, and the mixed gas is fully circulated by opening the throttle valve on t...

Embodiment 2

[0054] refer to figure 1 As shown, in the explosion-proof centrifugal fan of this embodiment, the electric power of the explosion-proof motor 10 is 18.5kW. The impeller 21 is made of 630 stainless steel, and its strength is 1.2 times the equivalent stress value of the maximum running speed. The casing 22 is made of 316 stainless steel, and has passed the impact test and can withstand an impact pressure of 1.0 MPa. The inner wall of the casing 22 is provided with a lining layer, which is made of stainless steel and has a thickness of 2mm. The axial and radial minimum one-sided gap between the impeller 21 and the casing 22 is 4 mm. The impeller 21 and the main shaft 31 are fixedly installed through a combination of a tapered bush and a flat key.

[0055] The explosion-proof centrifugal fan of this embodiment is subjected to a flame propagation test. The ethylene / air mixture is introduced into the test circuit pipeline, and the mixed gas is fully circulated by opening the throt...

Embodiment 3

[0061] refer to figure 1 As shown, in the explosion-proof centrifugal fan of this embodiment, the electric power of the explosion-proof motor 10 is 18.5kW. The impeller 21 is made of aluminum alloy, and its strength is 1.2 times the equivalent stress value of the maximum running speed. The casing 22 is made of cast iron and can withstand an impact pressure of 1.0 MPa through an impact test. The inner wall of the casing 22 is provided with a lining layer made of brass with a thickness of 2mm. The axial and radial minimum one-sided gap between the impeller 21 and the casing 22 is 5 mm. The impeller 21 and the main shaft 31 are fixedly installed through a combination of a tapered bush and a flat key.

[0062] The explosion-proof centrifugal fan of this embodiment is subjected to a flame propagation test. The ethylene / air mixture is introduced into the test circuit pipeline, and the mixed gas is fully circulated by opening the throttle valve on the test circuit until the air inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| explosion pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com