An arc electron source enhanced glow discharge surface activation process for PVD coating

A glow discharge and surface activation technology, which is applied in metal material coating process, sputtering coating, vacuum evaporation coating, etc., can solve the problems of rough and unsatisfactory workpiece surface, achieve high cleanliness, improve efficiency, The effect of reducing the risk of workpiece sparking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

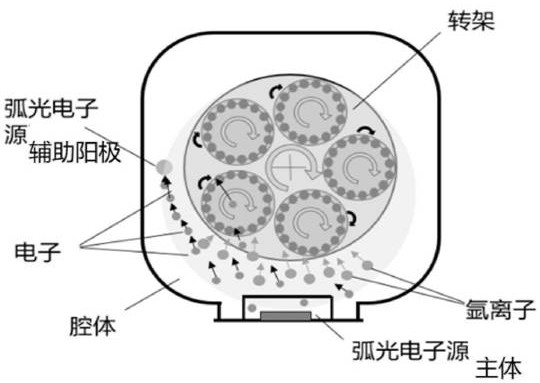

[0066] M2 high-speed steel surface activation process, using HC380 ion coating machine, using arc light electron source to assist surface activation, the principle is as follows figure 1 ,Specific steps are as follows

[0067] 1) Pre-treatment: Polish the HRC62-65 M2 high-speed steel sample after heat treatment, then ultrasonically clean it in alcohol for 10 minutes, dry it fully and put it into the vacuum chamber of the coating machine;

[0068] 2) Vacuuming: the background vacuum of the vacuum chamber is 5.0×10 -3 Pa;

[0069] 3) Heating to 500°C and keeping warm for 60 minutes;

[0070] 4) Enhanced cleaning of the arc electron source: Introduce argon gas, adjust the air pressure to 0.6Pa, turn on the arc electron source: turn on the main power supply of the arc electron source, adjust the cathode arc current to 60A; turn on the auxiliary anode, and adjust the current to 40A. Turn on the pulse bias power supply connected to the workpiece, adjust the negative bias voltage ...

Embodiment 2

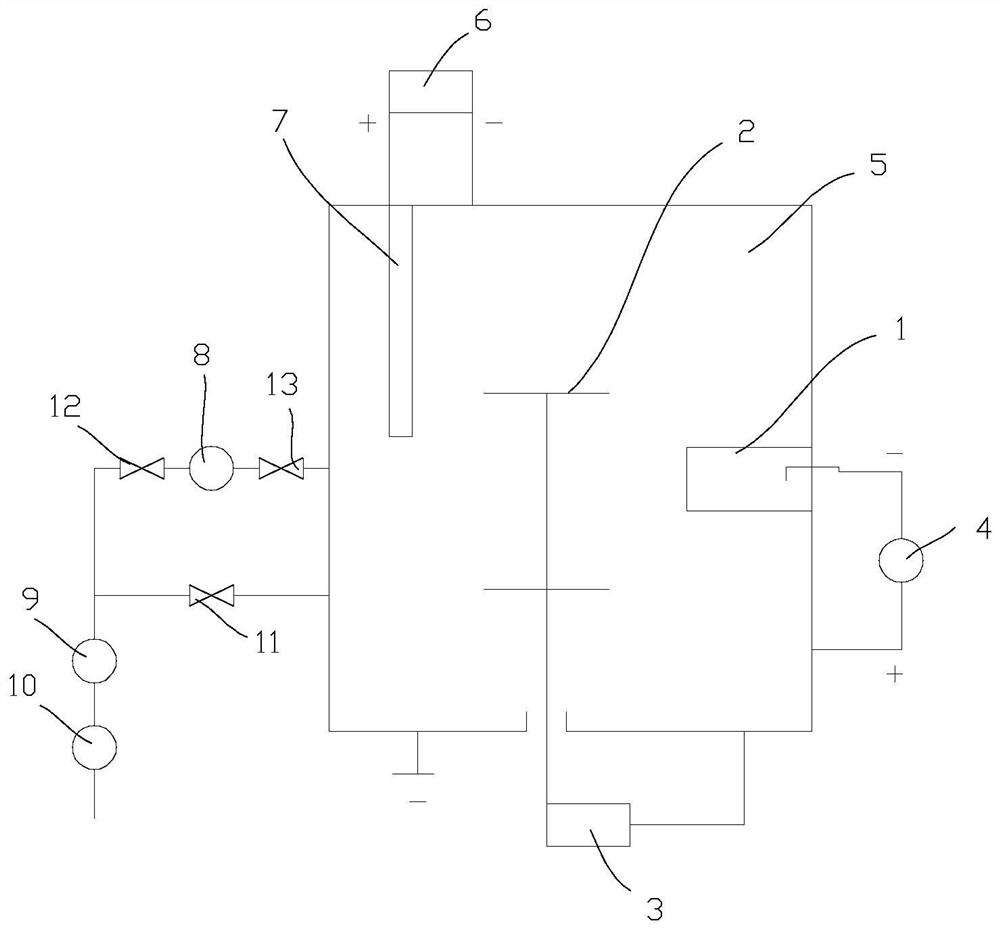

[0077] 304 stainless steel ion surface activation, use HC1912 ion coating machine, use arc light electron source to assist surface activation, the specific steps are as follows

[0078] 1. Pre-treatment: After polishing the 304 steel sample, perform ultrasonic cleaning in alcohol for 10 minutes, fully dry and put it into the vacuum chamber of the coating machine;

[0079] 2. Vacuuming: the background vacuum of the vacuum chamber is 3.0×10 -3 Pa;

[0080] 3. Heat to 200°C and keep warm for 30 minutes;

[0081] 4. Arc light electron source enhances etching activation: argon gas is introduced, and the pressure is adjusted to 0.8Pa. Turn on the main power supply of the arc electron source, adjust the current of the cathode arc target to 60A, turn on the auxiliary anode power supply of the arc electron source, and adjust the auxiliary anode current to 40A. Turn on the pulse bias power supply, adjust the negative bias voltage to 300V, the duty cycle is 50%, and use the arc electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com