Design and manufacturing method of high-power ultraviolet LED chip with vertical structure

A LED chip and vertical structure technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of small size, high manufacturing cost, and low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

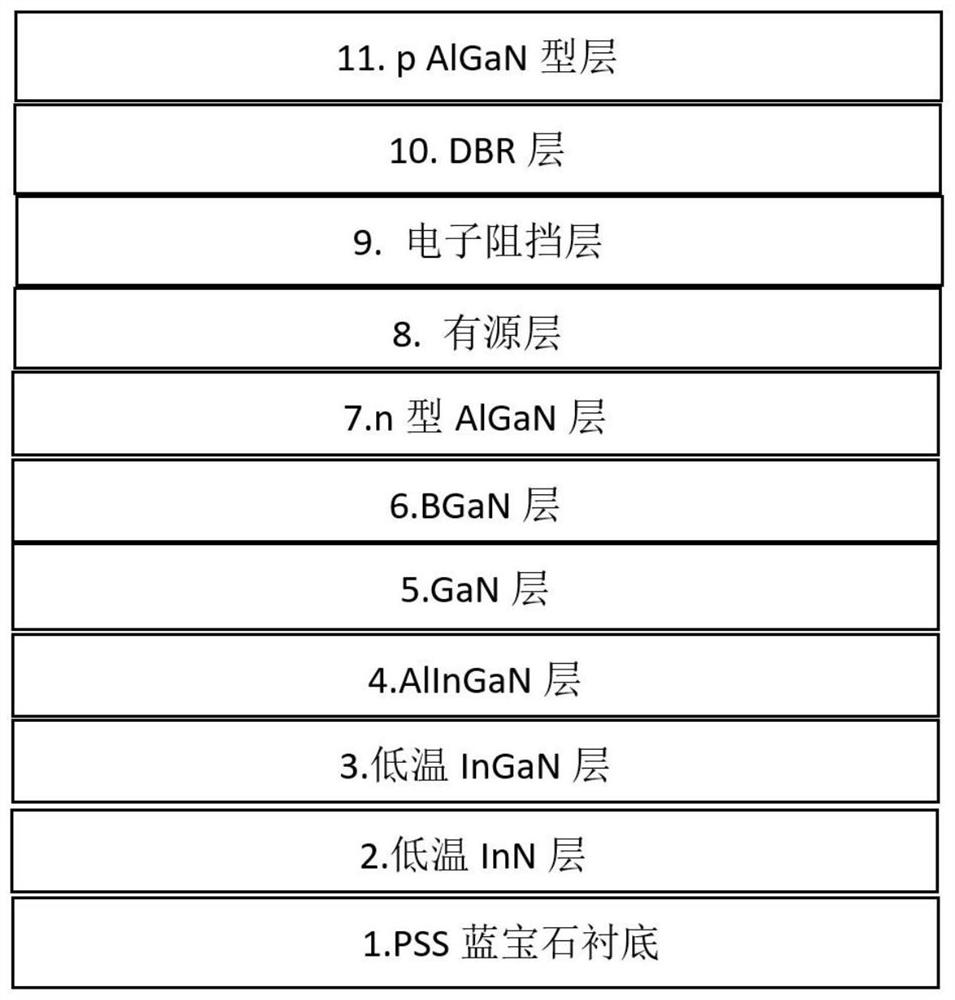

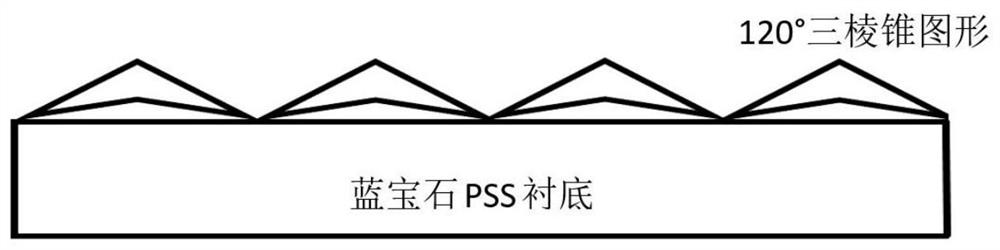

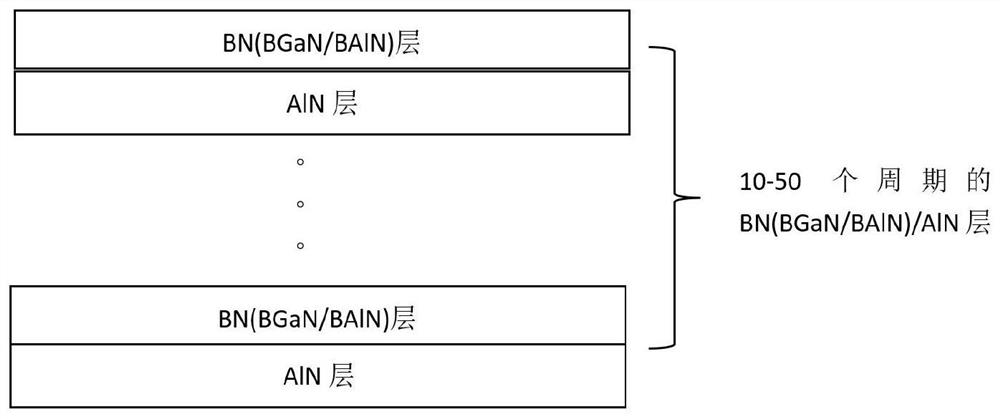

[0033] see Figure 1-5 , the present invention provides a technical solution: a design and manufacturing method of a high-power vertical structure ultraviolet LED chip, the design of the high-power vertical structure ultraviolet LED chip is as follows: a sapphire substrate is used as a growth substrate for heteroepitaxial growth, Using MOCVD technology to complete the entire epitaxial process, the sapphire substrate adopts an image substrate, that is, a PSS substrate. This substrate adopts a special design, which is a triangular pyramid structure with a vertex angle of 120°. A thin layer of low-temperature InN is grown on the PSS. Then grow a layer of InGaN, then grow a thin layer of AlGaInN, then grow a layer of high-temperature GaN, then grow a layer of n-type AlGaN, then grow an active layer, an electron blocking layer, and then grow a DBR reflective layer. The DBR layer is 10-50 BAlN or BGaN or BN and AlN periodic structure layers, doped with magnesium source and less sila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com