Manufacturing method of high-performance safe soft package lithium ion battery

A technology for ion batteries and manufacturing methods, which can be used in the manufacture of secondary batteries, battery pack components, and final products, and can solve problems such as difficulty in infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

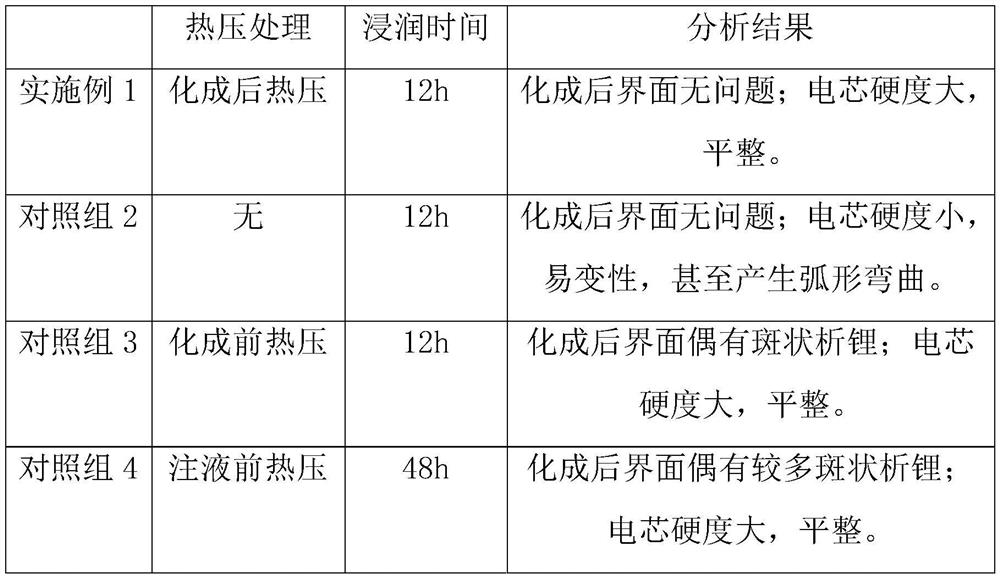

Examples

Embodiment 1

[0027] A method for manufacturing a high-performance safe soft-pack lithium-ion battery, specifically comprising the following steps:

[0028] (1) On the 12-micron thick PE base film, two layers of boehmite ceramic layers with a thickness of 2 microns are first coated, and then two layers of oil-based PVDF adhesive layers are coated using an intercoating process; the melting point of selected oil-based PVDF is 155±2℃, the width of each glued area in the oil-based PVDF adhesive layer is 3mm, and the width of each uncoated area is 0.5mm, the area of the glued area and the non-adhesive area in each oil-based PVDF adhesive layer The ratio is equal to six;

[0029] (2), use the above-mentioned separator to laminate through thermal compounding process, control the angle between the stripe direction of the separator and the direction of the bottom edge of the battery cell to be 45±10° during lamination, and prepare a stacked battery cell;

[0030] (3) After packaging, inject liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com