High-heat-flow short-time working platform phase change temperature control assembly fin structure design method

A short-time working and temperature-controlled component technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as overheating of equipment, unsatisfactory heat absorption efficiency, and influence of porosity and thermal conductivity, so as to improve working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with drawings and embodiments.

[0069] A fin structure design method for a phase change temperature control component of a high heat flow short-time working platform, comprising the following steps:

[0070] 1) Define design conditions:

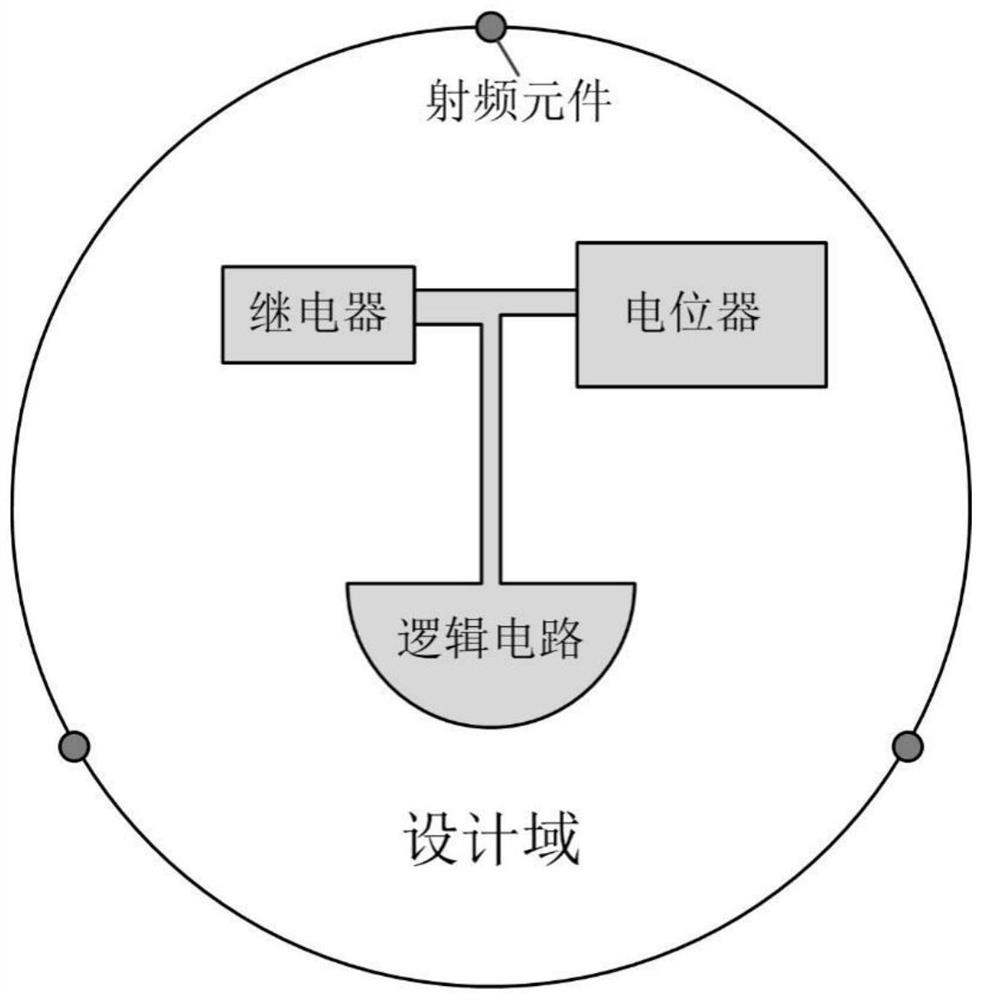

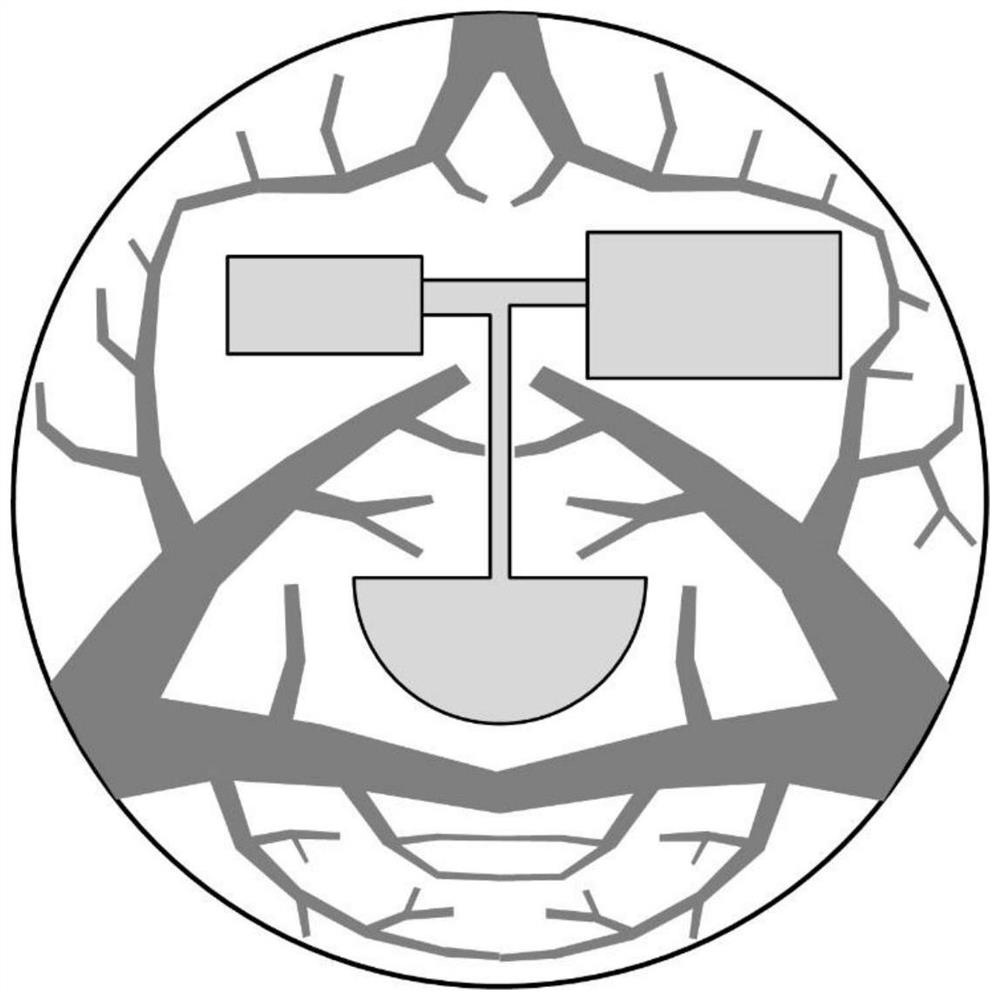

[0071] The area filled with phase-change materials in the thermal control device is taken as the design domain, and its periphery is the adiabatic boundary, and the fixed-point heat originates from the boundary of the design domain. The total area of the design domain is V D , the volume fraction of the overall high thermal conductivity material is limited to β 0 , the design domain of this embodiment is as figure 1 As shown, it can be seen from the figure that undesignable areas such as relays, potentiometers, and logic circuits can be equivalent to non-design areas. Metal fin design domain with variable material;

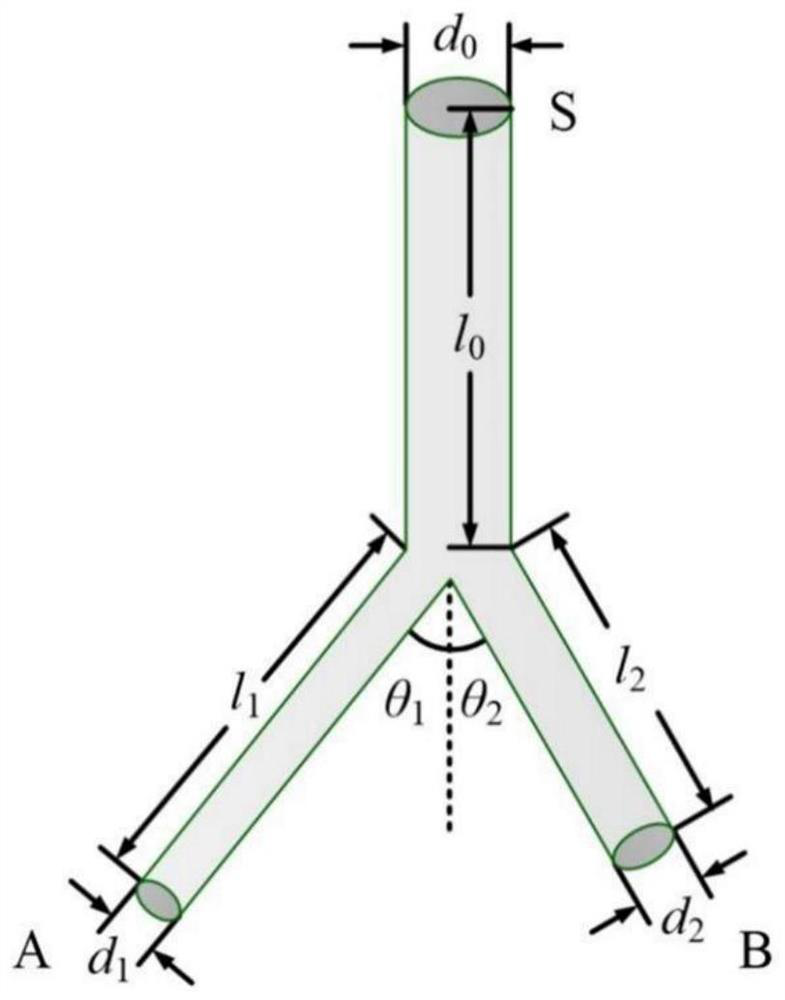

[0072] 2) Design heat conduction channels: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com