Method for cleaning etched semiconductor wafer

A semiconductor and post-cleaning technology, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficult to completely remove products and affect chip performance, and achieve strong repeatability. Avoid static electricity and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

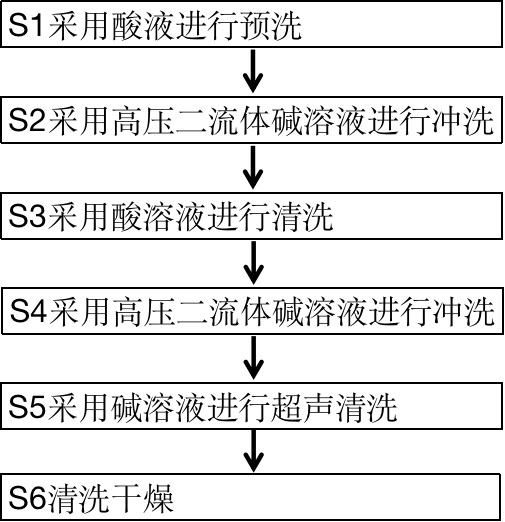

[0067] A method for cleaning a GaN semiconductor wafer after etching, characterized in that the cleaning method comprises the following steps:

[0068] S1 is pre-washed with acid solution; the acid pre-wash solution includes nitric acid, ozone and water, the temperature is 75 ° C, ultrasonic cleaning is used, and the frequency is 230KHz;

[0069] S2 is flushed with a high-pressure two-fluid alkaline solution; the high-pressure two-fluid alkaline cleaning solution contains sodium hydroxide and water, the volume ratio is 1.5:135, and the high pressure is 125 PSI, and the alkaline solution is used in the form of two fluids during the flushing process. Wafers are rinsed;

[0070] S3 is cleaned with an acid solution; the acid cleaning solution contains sulfuric acid, hydrogen peroxide and water at a temperature of 128°C, and ultrasonic cleaning is used at a frequency of 650KHz.

[0071] S4 uses a high-pressure two-fluid alkaline solution to rinse; the high-pressure alkaline cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com